A true partner right from the start

Voith Turbo - Germany

Contact us

Voith Turbo manufactures drive components that are firmly established in the everyday and high-end product markets. They provide the necessary pulling power for China‘s superfast ZEFIRO 380 train as well as for propelling buses and other vehicles all over the world. At its Garching factory near Munich, the company produces gearboxes, retarders and vibration dampers for commuter buses, goods vehicles, tractors and other vehicles. For over 40 years, Voith Turbo has relied upon DEA coordinate measuring machines from Hexagon Metrology in its Garching production facility and uses this trusted technology to ensure that everything fits.

This all began in 1969 with a manually operated DEA measuring machine. „The history of DEA coordinate measuring machines forms a vital piece of our history too,“ says Vladimir Bezner, who is responsible for quality assurance at Voith Turbo. Over a period of more than 40 years, Voith Turbo has invested in a total of ten DEA measuring machines. And most of the machines are still in use today by the company. During this time three DEA measuring machines were shipped from Bavaria to subsidiaries in Russia and Brazil – and are still faithfully performing their duties despite their impressive age. Vladimir Bezner is enthusiastic about his coordinate measuring machines: „Crucial to us at the time and still so today was the excellent price-performance ratio offered by DEA machines.“

This all began in 1969 with a manually operated DEA measuring machine. „The history of DEA coordinate measuring machines forms a vital piece of our history too,“ says Vladimir Bezner, who is responsible for quality assurance at Voith Turbo. Over a period of more than 40 years, Voith Turbo has invested in a total of ten DEA measuring machines. And most of the machines are still in use today by the company. During this time three DEA measuring machines were shipped from Bavaria to subsidiaries in Russia and Brazil – and are still faithfully performing their duties despite their impressive age. Vladimir Bezner is enthusiastic about his coordinate measuring machines: „Crucial to us at the time and still so today was the excellent price-performance ratio offered by DEA machines.“

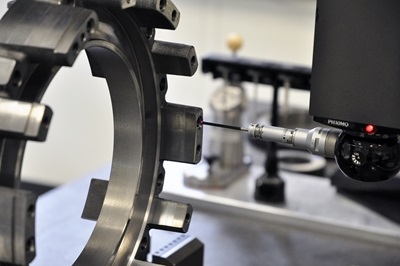

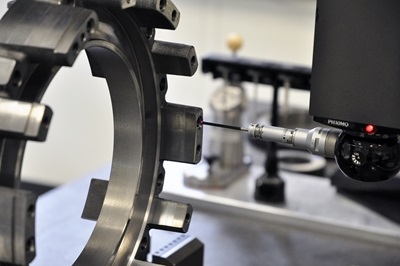

The situation at the Garching works today: two DEA Scirocco measuring machines, each with a measurement range of 1000 x 1500 x 900 mm, are used in the measuring room close to the production lines to inspect parts produced for gearboxes. A further DEA Scirocco 10.15.9 is available for the retarder and damper production lines. The team in the measuring room works a three-shift pattern to provide support to production with initial samples, intermediate checks and special inspections such as component audits. Form and position tolerances of disc carriers, planet-gear carriers or housings are examples of the inspected parameters. The usual tolerances here are of the order of a few hundredths of a millimetre.

The measurements are mainly performed by the metrology technicians: „Our team carries out over 90% of the measurement jobs in less than 45 minutes,“ says Bezner. For some tasks they rely on operator self-inspections. All the coordinate measuring machines have PC-DMIS metrology software installed on them and have been programmed for all the measurement processes. When performing their component inspections, the operatives work from an easy-to-follow user interface. One click on a photograph of the component is all it takes for the inspector to start the appropriate measuring program completely automatically.

The fourth in the quartet and almost a spring chicken in comparison – a DEA GLOBAL with a measurement range of 1200 x 3000 x 1000 mm and a measurement uncertainty of 2,2 + 3,3 L/1000 micrometres has its own place in a second, smaller measuring room. Voith Turbo exploits the full potential of this coordinate measuring machine above all on the initial sample inspection of supplier products. It is further employed for random checks on supplied parts, such as gearbox housings.

The fourth in the quartet and almost a spring chicken in comparison – a DEA GLOBAL with a measurement range of 1200 x 3000 x 1000 mm and a measurement uncertainty of 2,2 + 3,3 L/1000 micrometres has its own place in a second, smaller measuring room. Voith Turbo exploits the full potential of this coordinate measuring machine above all on the initial sample inspection of supplier products. It is further employed for random checks on supplied parts, such as gearbox housings.

Whether it‘s hardware or software, Hexagon Metrology products cannot help but impress. Starting with the DEA IOTA followed by the DEA Mistral and DEA Scirocco models right up to the current DEA GLOBAL series – Voith Turbo has been with Hexagon Metrology from the beginning and looks forward to a confident future.

This all began in 1969 with a manually operated DEA measuring machine. „The history of DEA coordinate measuring machines forms a vital piece of our history too,“ says Vladimir Bezner, who is responsible for quality assurance at Voith Turbo. Over a period of more than 40 years, Voith Turbo has invested in a total of ten DEA measuring machines. And most of the machines are still in use today by the company. During this time three DEA measuring machines were shipped from Bavaria to subsidiaries in Russia and Brazil – and are still faithfully performing their duties despite their impressive age. Vladimir Bezner is enthusiastic about his coordinate measuring machines: „Crucial to us at the time and still so today was the excellent price-performance ratio offered by DEA machines.“

This all began in 1969 with a manually operated DEA measuring machine. „The history of DEA coordinate measuring machines forms a vital piece of our history too,“ says Vladimir Bezner, who is responsible for quality assurance at Voith Turbo. Over a period of more than 40 years, Voith Turbo has invested in a total of ten DEA measuring machines. And most of the machines are still in use today by the company. During this time three DEA measuring machines were shipped from Bavaria to subsidiaries in Russia and Brazil – and are still faithfully performing their duties despite their impressive age. Vladimir Bezner is enthusiastic about his coordinate measuring machines: „Crucial to us at the time and still so today was the excellent price-performance ratio offered by DEA machines.“

Trusty trio promotes production

The situation at the Garching works today: two DEA Scirocco measuring machines, each with a measurement range of 1000 x 1500 x 900 mm, are used in the measuring room close to the production lines to inspect parts produced for gearboxes. A further DEA Scirocco 10.15.9 is available for the retarder and damper production lines. The team in the measuring room works a three-shift pattern to provide support to production with initial samples, intermediate checks and special inspections such as component audits. Form and position tolerances of disc carriers, planet-gear carriers or housings are examples of the inspected parameters. The usual tolerances here are of the order of a few hundredths of a millimetre.The measurements are mainly performed by the metrology technicians: „Our team carries out over 90% of the measurement jobs in less than 45 minutes,“ says Bezner. For some tasks they rely on operator self-inspections. All the coordinate measuring machines have PC-DMIS metrology software installed on them and have been programmed for all the measurement processes. When performing their component inspections, the operatives work from an easy-to-follow user interface. One click on a photograph of the component is all it takes for the inspector to start the appropriate measuring program completely automatically.

Supplier check with DEA GLOBAL

The fourth in the quartet and almost a spring chicken in comparison – a DEA GLOBAL with a measurement range of 1200 x 3000 x 1000 mm and a measurement uncertainty of 2,2 + 3,3 L/1000 micrometres has its own place in a second, smaller measuring room. Voith Turbo exploits the full potential of this coordinate measuring machine above all on the initial sample inspection of supplier products. It is further employed for random checks on supplied parts, such as gearbox housings.

The fourth in the quartet and almost a spring chicken in comparison – a DEA GLOBAL with a measurement range of 1200 x 3000 x 1000 mm and a measurement uncertainty of 2,2 + 3,3 L/1000 micrometres has its own place in a second, smaller measuring room. Voith Turbo exploits the full potential of this coordinate measuring machine above all on the initial sample inspection of supplier products. It is further employed for random checks on supplied parts, such as gearbox housings.

Capacity bonus from offline programming

The investment in a PC-DMIS offline programming station has paid off handsomely for Voith Turbo, Garching. The design department at Voith Turbo‘s HQ in Heidenheim creates CAD models, which form the base data. PC-DMIS was the first metrology software to bring CAD data into the measuring room and is therefore ideal for these applications. Metrology technician Alfred Schadenfroh uses the CAD data as the basis for the programming. „I can extract the volumetric model from the I-DEAS CAD program and use it to create the measuring program offline,“ says Schadenfroh. „Compared to our previous practice, where we would have done the programming on the coordinate measuring machine for the gearbox production line, we have raised our capacity by 30% – thanks to the offline programming station.“Whether it‘s hardware or software, Hexagon Metrology products cannot help but impress. Starting with the DEA IOTA followed by the DEA Mistral and DEA Scirocco models right up to the current DEA GLOBAL series – Voith Turbo has been with Hexagon Metrology from the beginning and looks forward to a confident future.