Ready for departure

MTU Aero Engines - Germany

Contact us

Boarding a plane to fly from one continent to another within hours has become an everyday event for us. Behind that are over a hundred years of aviation history and a great deal of high tech, such as engines produced by MTU Aero Engines. In its quality assurance, MTU relies on the power of measuring systems by Hexagon Metrology.

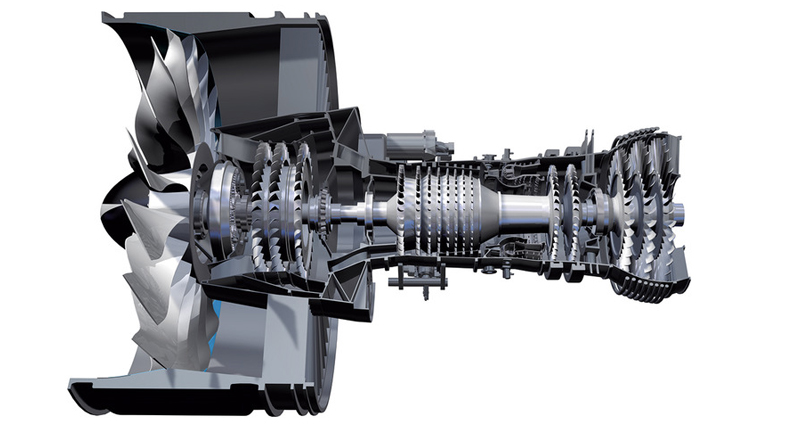

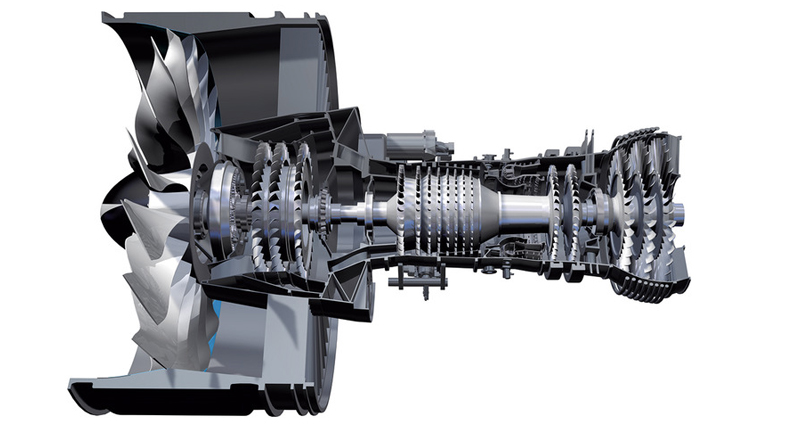

MTU Aero Engines develops, produces, sells and maintains civil and military engines for airplanes and helicopters, as well as industrial gas turbines. A key success element in the MTU portfolio is the geared turbofan jet engine, a joint venture project with the USA-based aviation company Pratt & Whitney.

MTU takes care of the first four stages for the highpressure compressor - a blisk construction amongst others - and contributes the fast-turning low-pressure turbine. From a production technology point of view, blisks are complex components in which blades and disks are integrated in one component. Pratt & Whitney is happy that its order books are continually swelling. The increase in orders presents a challenge for MTU: it is intended to increase the production of the technically sophisticated blisks at the main MTU facility in Munich from 600 to 3,500 pieces by 2016. A steep ramp-up.

In order to be able to cope with the order volume, MTU has built a 10,000 square metre large building on the company site in Munich especially for this purpose. The infrastructure in this building, including the measuring room, has been designed to exactly suit the work processes.

In order to be able to cope with the order volume, MTU has built a 10,000 square metre large building on the company site in Munich especially for this purpose. The infrastructure in this building, including the measuring room, has been designed to exactly suit the work processes.

"Our basic philosophy is to have very stable production processes", explains Stefan Hertling, Director Quality Inspection Production at MTU. "To achieve that, we need metrology which we can use to check the blisks as efficiently as possible. Short measuring times, reduced measurement uncertainty, process stability and evidence of test instrument capability were the main criteria in the search for a metrology partner."

In preparation for the new blisk competence centre, MTU organised a competition in which ten measuring system manufacturers took part. It was a fair competition in which Germany‘s leading jet engine manufacturer commissioned the participants to carry out critical metrology tasks on a sample component with typical characteristics and profile errors. In the end, Hexagon Metrology PTS prevailed as the winner. Hexagon Metrology PTS proposed a high-precision Leitz PMM-C coordinate measuring machine with integrated rotary table, the flexible QUINDOS software and the option for offline programming using the I++ Simulator.

With the winning system, it was possible to drastically shorten the measuring times stipulated by MTU. When measuring the sample component, Hexagon Metrology PTS achieved an overall measuring time that was reduced by 65% while maintaining test process capability. The measuring time for the blade profiles was reduced even more - by 75%. Stefan Hertling: "The option of being able to produce measuring programmes offline is also a massive improvement. This means that we can use the measuring machines exclusively for our own measuring tasks." Thanks to the offline programming, MTU is no longer tied to the production cycle. They no longer need the operator, the machine or the blisk in its physical form to produce a programme. The measuring process is completely programmed and optimised in the virtual measuring environment, which is a 100 percent representation of the real measuring situation, including the machine, the component, fixturing and probe configurations etc. This is where the I++ Simulator software package by Hexagon Metrology PTS is useful.

Both partners opted for very close cooperation right from the very start. Hexagon Metrology PTS also provided much support at the programming stage. "We are determined to produce efficient measuring programmes that are available in time for blisk production. In order to ensure this in the face of this steep ramp-up, it was clear that we would need expert support for this software, which is new for us. The cooperation was very close and successful", says Hertling.

Both partners opted for very close cooperation right from the very start. Hexagon Metrology PTS also provided much support at the programming stage. "We are determined to produce efficient measuring programmes that are available in time for blisk production. In order to ensure this in the face of this steep ramp-up, it was clear that we would need expert support for this software, which is new for us. The cooperation was very close and successful", says Hertling.

The geometries to be included in the programme were not just of the standard type. Helmut Müller, Managing Director of Hexagon Metrology PTS, followed the project very closely: "Measuring blisks is highly complicated. In addition to normal geometries, there are free-form surfaces, blade profiles, the position of the blades and other characteristics to be taken into account. The objective was to be able to run each blisk programme on each coordinate measuring machine. At the same time it was important to keep the operation manageable - in spite of the fact that the underlying software is very versatile. Furthermore, we aimed to have as few different key combinations as possible. We had to do much preparatory work to establish this infrastructure."

The effort has proved to be worth it. The total of eight Leitz PMM-C measuring machines are being installed step by step and in the same configuration. Using a standard fixturing system, the ten-strong metrology team of MTU Aero Engines is able to clamp all types of blisks, as well as measure these items during production and carry out a final inspection. MTU is ready for departure thanks to the measurement concept provided by Hexagon Metrology PTS.

MTU Aero Engines develops, produces, sells and maintains civil and military engines for airplanes and helicopters, as well as industrial gas turbines. A key success element in the MTU portfolio is the geared turbofan jet engine, a joint venture project with the USA-based aviation company Pratt & Whitney.

MTU takes care of the first four stages for the highpressure compressor - a blisk construction amongst others - and contributes the fast-turning low-pressure turbine. From a production technology point of view, blisks are complex components in which blades and disks are integrated in one component. Pratt & Whitney is happy that its order books are continually swelling. The increase in orders presents a challenge for MTU: it is intended to increase the production of the technically sophisticated blisks at the main MTU facility in Munich from 600 to 3,500 pieces by 2016. A steep ramp-up.

Metrology experts required

In order to be able to cope with the order volume, MTU has built a 10,000 square metre large building on the company site in Munich especially for this purpose. The infrastructure in this building, including the measuring room, has been designed to exactly suit the work processes.

In order to be able to cope with the order volume, MTU has built a 10,000 square metre large building on the company site in Munich especially for this purpose. The infrastructure in this building, including the measuring room, has been designed to exactly suit the work processes."Our basic philosophy is to have very stable production processes", explains Stefan Hertling, Director Quality Inspection Production at MTU. "To achieve that, we need metrology which we can use to check the blisks as efficiently as possible. Short measuring times, reduced measurement uncertainty, process stability and evidence of test instrument capability were the main criteria in the search for a metrology partner."

In preparation for the new blisk competence centre, MTU organised a competition in which ten measuring system manufacturers took part. It was a fair competition in which Germany‘s leading jet engine manufacturer commissioned the participants to carry out critical metrology tasks on a sample component with typical characteristics and profile errors. In the end, Hexagon Metrology PTS prevailed as the winner. Hexagon Metrology PTS proposed a high-precision Leitz PMM-C coordinate measuring machine with integrated rotary table, the flexible QUINDOS software and the option for offline programming using the I++ Simulator.

Drastically improved

With the winning system, it was possible to drastically shorten the measuring times stipulated by MTU. When measuring the sample component, Hexagon Metrology PTS achieved an overall measuring time that was reduced by 65% while maintaining test process capability. The measuring time for the blade profiles was reduced even more - by 75%. Stefan Hertling: "The option of being able to produce measuring programmes offline is also a massive improvement. This means that we can use the measuring machines exclusively for our own measuring tasks." Thanks to the offline programming, MTU is no longer tied to the production cycle. They no longer need the operator, the machine or the blisk in its physical form to produce a programme. The measuring process is completely programmed and optimised in the virtual measuring environment, which is a 100 percent representation of the real measuring situation, including the machine, the component, fixturing and probe configurations etc. This is where the I++ Simulator software package by Hexagon Metrology PTS is useful.

Close cooperation

Both partners opted for very close cooperation right from the very start. Hexagon Metrology PTS also provided much support at the programming stage. "We are determined to produce efficient measuring programmes that are available in time for blisk production. In order to ensure this in the face of this steep ramp-up, it was clear that we would need expert support for this software, which is new for us. The cooperation was very close and successful", says Hertling.

Both partners opted for very close cooperation right from the very start. Hexagon Metrology PTS also provided much support at the programming stage. "We are determined to produce efficient measuring programmes that are available in time for blisk production. In order to ensure this in the face of this steep ramp-up, it was clear that we would need expert support for this software, which is new for us. The cooperation was very close and successful", says Hertling.The geometries to be included in the programme were not just of the standard type. Helmut Müller, Managing Director of Hexagon Metrology PTS, followed the project very closely: "Measuring blisks is highly complicated. In addition to normal geometries, there are free-form surfaces, blade profiles, the position of the blades and other characteristics to be taken into account. The objective was to be able to run each blisk programme on each coordinate measuring machine. At the same time it was important to keep the operation manageable - in spite of the fact that the underlying software is very versatile. Furthermore, we aimed to have as few different key combinations as possible. We had to do much preparatory work to establish this infrastructure."

The effort has proved to be worth it. The total of eight Leitz PMM-C measuring machines are being installed step by step and in the same configuration. Using a standard fixturing system, the ten-strong metrology team of MTU Aero Engines is able to clamp all types of blisks, as well as measure these items during production and carry out a final inspection. MTU is ready for departure thanks to the measurement concept provided by Hexagon Metrology PTS.