Quality from challenging processes to mass-production processing

Since its establishment and across decades of development and manufacturing, Kotobuki Seiko has always relied on high-quality measurement machines and the support offered by Hexagon in Japan to ensure the quality of their business

Kotobuki Seiko’s President Kenji Kimura made up his mind to establish a company when he was in his 20s, with the vision of creating products using his own innovative methods.

Today, Kotobuki Seiko engages in a wide range of manufacturing operations, from lathe turning to machining and composite processing, while focusing mainly on cutting operations related to aluminum and various other materials. The company is committed to manufacturing, development, technological improvement and product creation under the motto of “Satisfying our customers’ diverse needs by making full use of advanced technology”.

“At the time of our founding, we were mainly engaged in difficult-to-machine processes that no other company had the capacity to handle,” explains Kenji Kimura. “Recently, we have been focusing more on the manufacture of mass-produced parts. We are expanding the scope of our manufacturing in response to the needs of the times, while naturally taking on the challenges of new technology.”

“At the time of our founding, we were mainly engaged in difficult-to-machine processes that no other company had the capacity to handle,” explains Kenji Kimura. “Recently, we have been focusing more on the manufacture of mass-produced parts. We are expanding the scope of our manufacturing in response to the needs of the times, while naturally taking on the challenges of new technology.”

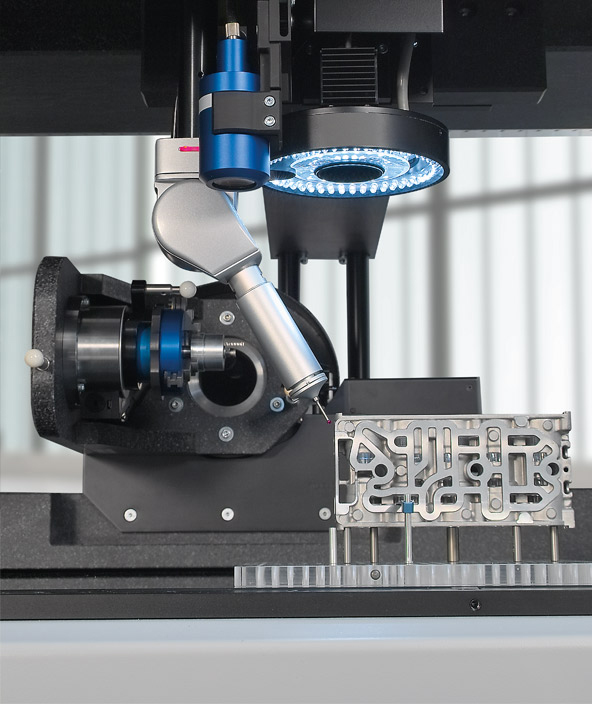

The first Hexagon product Kotobuki Seiko used was a multisensor vision machine, installed about 20 years ago. “It was much better at detecting the edges of a chamfer than the competition – that is why we chose Hexagon’s product,” recalls Kenji Kimura.

“In terms of product functionality, the software interface is very easy to use, and the measured values are good because they are consistent with the accuracy of our various machines. No matter which tool we are measuring, we get the same accuracy.”

“Speed is essential when launching a product in the machining industry, and the repeatable accuracy of Hexagon’s product during trial processing and measurement contributes to high precision during the dimensional matching and setup stages, resulting in faster launch speeds.”

Kotobuki Seiko Executive Vice President Takeshi Kimura also appreciated the ‘cool look’ of the machine: “I like the design of the Global S, including the very practical LEDs, because it matches the design of our metrology lab. Appearance is also important and the employees like to work with nice looking machines.”

Regarding service and support, Kotobuki Seiko has been very satisfied with Hexagon’s local offering. “I still remember the support after the purchase,” says Kenji Kimura. “I still remember that at the end of last year, when we had a problem that we had no way to solve by ourselves, they helped us out a lot. Even though it was the end of the year holidays, it was still work, and deadlines do not wait for us. It is very helpful to have an environment where we can get immediate help when we need it.”

Measuring is an essential step, but analysis before starting a large production project is also important. “I think the need for analysis at various stages of production will continue to increase, and will lead to a stable production of products,” explains Kenji Kimura. “Nowadays, nobody can allow themselves to find that something was not right during one part of the production process. Now that we have the means of analysis, including various technologies allowing us full flexibility, we know in advance where the stress will be applied, so we can determine where and how best to reduce the stress during machining, and where to place the support during machining.

Measuring is an essential step, but analysis before starting a large production project is also important. “I think the need for analysis at various stages of production will continue to increase, and will lead to a stable production of products,” explains Kenji Kimura. “Nowadays, nobody can allow themselves to find that something was not right during one part of the production process. Now that we have the means of analysis, including various technologies allowing us full flexibility, we know in advance where the stress will be applied, so we can determine where and how best to reduce the stress during machining, and where to place the support during machining. “For example, strength analysis can be used to apply loads to tools, so if we have analysis, we can simulate in advance how the product will bend and how it will be bent, so we can make a jig and apply a machining load. Especially when the product is not a block but a thin die-cast or forged product, the thickness of the product changes rapidly, and the product bends when machining is applied to it. By analysing how the fixture accommodates these changes and incorporating the results into fixture design internally, we can achieve better results. We link the analysis results with fixture installation to streamline work processes and reduce time requirements.”

“For example, strength analysis can be used to apply loads to tools, so if we have analysis, we can simulate in advance how the product will bend and how it will be bent, so we can make a jig and apply a machining load. Especially when the product is not a block but a thin die-cast or forged product, the thickness of the product changes rapidly, and the product bends when machining is applied to it. By analysing how the fixture accommodates these changes and incorporating the results into fixture design internally, we can achieve better results. We link the analysis results with fixture installation to streamline work processes and reduce time requirements.”Thanks to this process, the company can create more quality products, while shortening their manufacturing times.

“And this is all also thanks to Hexagon,” concludes Kotobuji Seiko’s President Kenji Kimura.