Quality at first sight

SEAT - Spain.

Contact us

SEAT, which is part of the Volkswagen group, doesn’t just manufacture cars to very high levels of technical performance. It also ensures its customers perceive its cars’ quality at a glance. The look, touch and feel of a car are an important part of the overall customer experience, with perceived quality playing an essential role in any buying decision.

SEAT’s technical measuring centre at its headquarters in Martorell, outside Barcelona, demonstrates the company’s commitment to perfecting all aspects of how its customers experience its cars.

The Spanish company produces more than 440,000 cars annually at its Martorell site, including its popular Arona and Ibiza ranges and the Audi A1. At the technical measuring centre metrology tools and software from Hexagon Manufacturing Intelligence help ensure that the 4,000 pieces that make up each car fit together perfectly as a whole.

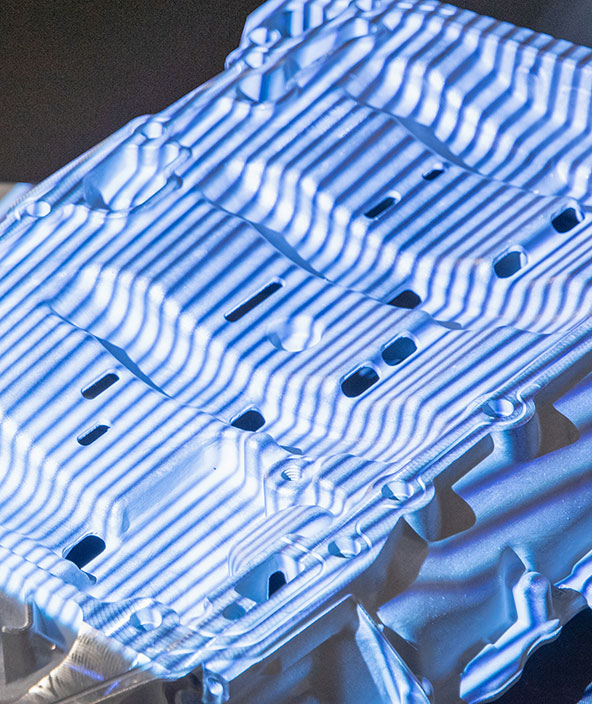

The breadth of Hexagon’s tools and software enables SEAT’s quality control teams to always choose the most effective instrument for the job, whether it’s a probe to measure shiny or transparent surfaces, or a white light scanner to analyse fit and finish.

Together Hexagon’s 3D probing and scanning technologies allow SEAT’s metrology teams to measure and capture data from components, serial produced parts, sub-assemblies and prototype vehicles. The Absolute Arm from Hexagon, for example, supports seamless switching between a tactile probe and a laser scanning tool so that the operator can move easily between applications, geometries and surface types. The Leica Absolute Tracker lets them measure large volumes quickly in a single set-up, as well as capturing data in difficult to reach areas. And the WLS400M white light scanner system captures both large and small surfaces quickly and reliably.

Hexagon’s software also helps SEAT use metrology data effectively. The Financial Times in 2018 recognised SEAT as a European leader in digitalisation and being able to capture and analyse quality control data quickly and then act on the information is crucial to the Martorell site’s operations.

With Hexagon’s software, SEAT’s engineers can quickly qualify the dimensional fit and finish of the exterior and interior of the vehicle and identify whether they need to take action. And because they are capturing data digitally, they can share analysis and insight both internally and with suppliers, who can make any necessary adjustments.

PC-DMIS, which is the world’s most widely deployed measurement software, is among the Hexagon software tools deployed at Martorell. Others include CoreView, which combines visualisation and analysis capabilities to let operators pinpoint the root cause of a problem and ascertain how to resolve it and Q-DAS statistical process control solutions.

“Several years ago, we could make one measurement per second with touch technology. Today, it is complemented by photogrammetry and laser scanning, boosting our capacity to 200,000 measurements,” explains Pedro Vallejo, head of measurement technology and Meisterbock at SEAT.

“These developments give us much more information and enable us to understand the performance of each car part in less time, making it much more effective to introduce improvements.”

SEAT’s technical measuring centre at its headquarters in Martorell, outside Barcelona, demonstrates the company’s commitment to perfecting all aspects of how its customers experience its cars.

The Spanish company produces more than 440,000 cars annually at its Martorell site, including its popular Arona and Ibiza ranges and the Audi A1. At the technical measuring centre metrology tools and software from Hexagon Manufacturing Intelligence help ensure that the 4,000 pieces that make up each car fit together perfectly as a whole.

The breadth of Hexagon’s tools and software enables SEAT’s quality control teams to always choose the most effective instrument for the job, whether it’s a probe to measure shiny or transparent surfaces, or a white light scanner to analyse fit and finish.

Together Hexagon’s 3D probing and scanning technologies allow SEAT’s metrology teams to measure and capture data from components, serial produced parts, sub-assemblies and prototype vehicles. The Absolute Arm from Hexagon, for example, supports seamless switching between a tactile probe and a laser scanning tool so that the operator can move easily between applications, geometries and surface types. The Leica Absolute Tracker lets them measure large volumes quickly in a single set-up, as well as capturing data in difficult to reach areas. And the WLS400M white light scanner system captures both large and small surfaces quickly and reliably.

Hexagon’s software also helps SEAT use metrology data effectively. The Financial Times in 2018 recognised SEAT as a European leader in digitalisation and being able to capture and analyse quality control data quickly and then act on the information is crucial to the Martorell site’s operations.

With Hexagon’s software, SEAT’s engineers can quickly qualify the dimensional fit and finish of the exterior and interior of the vehicle and identify whether they need to take action. And because they are capturing data digitally, they can share analysis and insight both internally and with suppliers, who can make any necessary adjustments.

PC-DMIS, which is the world’s most widely deployed measurement software, is among the Hexagon software tools deployed at Martorell. Others include CoreView, which combines visualisation and analysis capabilities to let operators pinpoint the root cause of a problem and ascertain how to resolve it and Q-DAS statistical process control solutions.

“Several years ago, we could make one measurement per second with touch technology. Today, it is complemented by photogrammetry and laser scanning, boosting our capacity to 200,000 measurements,” explains Pedro Vallejo, head of measurement technology and Meisterbock at SEAT.

“These developments give us much more information and enable us to understand the performance of each car part in less time, making it much more effective to introduce improvements.”

With thanks to SEAT for supplying the video and for their support.