Pretty tight ...

Contact us

Pretty tight these are the manufacturing tolerances for aeronautical parts at BBAT in Wildau/Brandenburg. They manufacture rotor housings for jet engines in small volumes using m&h touch probes and software 3D Form Inspect.

Plus or minus 2 hundredths on diameters from 500mm to 800mm in relatively thin-walled housings made of tough heat-resistant steel – these are the accuracy challenges BBAT faces every day. They manufacture small quantities of housing components for jet engines, inside which air end turbine blades run. These components are used in several turbine engines for business jets and small commercial aircraft.

BBAT, or Berlin Brandenburg Aerospace Technology AG, is a joint venture of several suppliers to the aeronautical industry which, since 2008, has specialised in manufacturing out problems on these highly sophisticated turbine components. At BBAT, the turbine rings are mechanically machined and coated. The components are delivered to the engine manufacturers’ assembly department ready for installation.

BBAT, or Berlin Brandenburg Aerospace Technology AG, is a joint venture of several suppliers to the aeronautical industry which, since 2008, has specialised in manufacturing out problems on these highly sophisticated turbine components. At BBAT, the turbine rings are mechanically machined and coated. The components are delivered to the engine manufacturers’ assembly department ready for installation.

Clamping and cutting of the tough materials and relatively unstable components is particularly difficult. Close tolerances must be achieved on the machine with a high degree of reliability as any errors detected later cannot be easily corrected. Reclamping a component on the machine for reworking is almost impossible and not advisable in terms of cost-efficiency and on-schedule manufacturing.

To alleviate these potential problems they have attached particular importance to the selection of tooling and ancillary equipment. In a temperature-controlled workshop they machine on 5-axis Alzmetall machining centres equipped with the Siemens 840D control. High repeatability is as important as troublefree manufacturing for small batch production. Only clamping twice, the turbine housings are completely machined using both milling and turning cycles. BBAT achieves the required close tolerances of only 4 hundredths using a sophisticated manufacturing cycle with integrated measurement on the machine using touch probes and 3D Form Inspect software from m&h. “Without m&h we would need expensive gauges and special equipment”, tells Klaus Hanreich. “As well as additional costs, this would mean high expenditure of time plus the danger of individual errors.”

To alleviate these potential problems they have attached particular importance to the selection of tooling and ancillary equipment. In a temperature-controlled workshop they machine on 5-axis Alzmetall machining centres equipped with the Siemens 840D control. High repeatability is as important as troublefree manufacturing for small batch production. Only clamping twice, the turbine housings are completely machined using both milling and turning cycles. BBAT achieves the required close tolerances of only 4 hundredths using a sophisticated manufacturing cycle with integrated measurement on the machine using touch probes and 3D Form Inspect software from m&h. “Without m&h we would need expensive gauges and special equipment”, tells Klaus Hanreich. “As well as additional costs, this would mean high expenditure of time plus the danger of individual errors.”

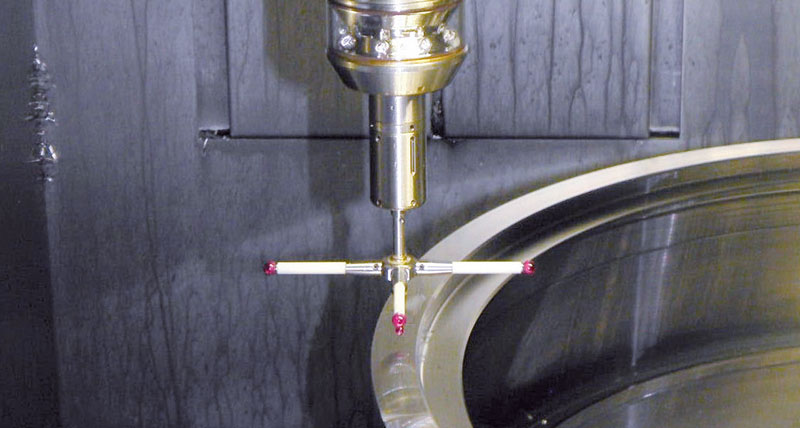

3D Form Inspect compares the contours from CAD engineering with the actual dimensions of the workpiece while it is still clamped on the machine. The geometries being measured can already be determined on the CAD drawing or with a mouse click on a computer in the workshop at any time. The software generates the touch probe programme and executes collision control with the workpiece contours. The 5-axis version also enables the measuring of undercuts and geometries inclined in space. Swivelling errors of the 4th and 5th axis are automatically compensated. Size and contours of all m&h touch probes and styli, optional extensions and crossform styli are saved in the software and taken into consideration. The software is capable of managing several touch probes in different combinations. This not only achieves reduced programming effort but also creates operational safety. Calibration of touch probes on a measuring sphere registers thermal and static changes on the machine and ensures reliable measuring values.

We would not be able to manufacture like this without m&h.

Turbine rings, made of hard to cut nickel-chromium steel, are measured before and after finishing. Thus workpieces remain clamped on the machine until they are sure that the close tolerance of +/- 2 hundredths has been achieved. “Without this technology, cost-efficient manufacture would not be possible,” states managing director Klaus Hanreich. A lot of measuring values can be found using the probing cycles inside the Siemens 840D control but they are not sufficient to generate all the required measuring values on the workpiece. This is why Klaus Hanreich adds: “It doesn’t work without m&h software”.

At BBAT, they have invested a lot of time and energy developing a closed evaluation loop for measuring values, verification and resulting conclusions for the respective machining programmes. The measured values flow into a self-developed programming routine that not only detects possible false measurements but also creates a reference to the machining parameters and tool data by multiple measurements and statistical evaluations. The operator can immediately take the correction values required for finish machining from these lists. This is an individual feedback solution created by BBAT which requires always using the same machining programmes. Over time, BBAT has further optimised the process and has been able to shorten the necessary measuring routines. “Initially, measuring took us about 2 hours per workpiece,” tells Klaus Hanreich. “Today, it takes us around 5 minutes.”

At BBAT, they have invested a lot of time and energy developing a closed evaluation loop for measuring values, verification and resulting conclusions for the respective machining programmes. The measured values flow into a self-developed programming routine that not only detects possible false measurements but also creates a reference to the machining parameters and tool data by multiple measurements and statistical evaluations. The operator can immediately take the correction values required for finish machining from these lists. This is an individual feedback solution created by BBAT which requires always using the same machining programmes. Over time, BBAT has further optimised the process and has been able to shorten the necessary measuring routines. “Initially, measuring took us about 2 hours per workpiece,” tells Klaus Hanreich. “Today, it takes us around 5 minutes.”

When asked about the main effects of integrated measuring on the machine, his response is enthusiastic. “Pre-inspection on the machine provides reliability of the production process. We are able to control the results of the cutting process from an early stage and react immediately if needed. Now the influences of tools and cutting can be determined and corrected. This allows high precision while safely maintaining such close tolerances“.

The pride in his words comes from many tests, inhouse software expansions and continuous improvement. They know that one of their customers tried to manufacture the components themselves to the same reliability but within a comparably short period of time they’d failed. “Measuring on the machine using m&h is just one link in our excellent process chain but it’s a particularly important one”. Klaus Hanreich sums up, “We would certainly do it again the same way”.