Nobody gets past security

Kiekert - Germany

Contact us

Night club doormen mercilessly decide who can spend the evening in the club and who has to peep through steamed-up windows in their trainers from the outside. The Optiv Classic measuring devices from Hexagon Metrology perform the same function at Kiekert. At the incoming goods department, they check vendor parts and issue a decisive "go" or "no go".

Kiekert AG is the world‘s leading supplier of high-quality locking system technology for the automotive industry. With development and production locations across the globe, the locking system specialist is locally accessible to customers in every major automotive region of the world. The company‘s particular focus on high-quality product development is mirrored in their modern product range. Over a third of their technologies are less than three years old and make Kiekert the world‘s number-one provider of sidedoor locking systems. The same high quality standards apply at every Kiekert production location – it‘s what the company‘s international customers expect.

At first glance, a car lock seems like a trivial thing. Global Laboratory Manager Bettina Brandt puts things into perspective: “A lock is quite comparable to a Swiss watch. Between 70 and 125 individual parts interlock with and engage one another. Deviations in the hundredth of a millimetre range in a single part can result in lock malfunction.” Ultimately, every Kiekert lock has to lock reliably and open just as reliably. This is ensured thanks to the high standard of quality in every area of the business.

Klaus Hense, Senior Manager of Global Supplier Quality, explained: “Naturally, we conduct advance quality planning with our suppliers, carry out audits and have put best practices in place. Without a filter in our incoming goods department, there would always be a risk of a defective part slipping through. We continuously develop and refine our incoming goods inspection to keep it up to date.”

A few years ago, each factory still developed its own methodology for incoming goods inspection. The factory in Mexico, for example, produced expensive, typebound gauge sets for each vendor part. Since costs tended to continue rising, attempts were made to find another solution.

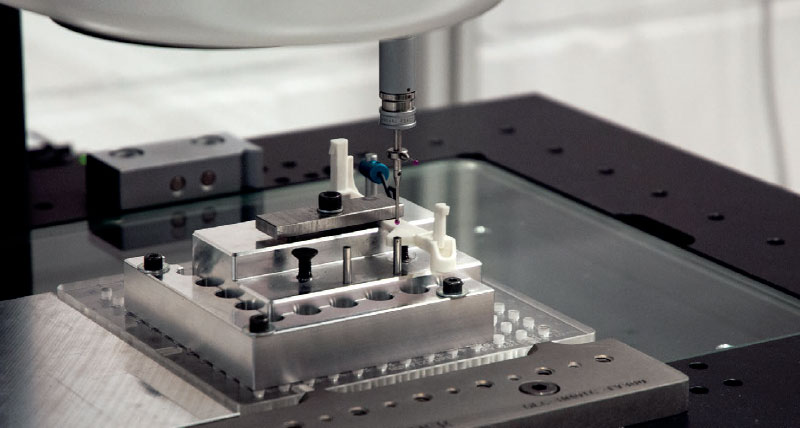

Since 2012, Kiekert have been using a globally uniform, measuring, documenting and assessable solution, the Optiv Classic 321 GL multi-Sensor measuring systems from Hexagon Metrology, which are compatible with the latest standards and with every vendor part. These change-friendly systems enable Kiekert to keep up with the dynamics of the automotive market and its frequent model changes.

Global concept implemented locally

In the meantime, all Kiekert factories have been outfitted with identical CNC-controlled 3D measuring machines. This ensures that the measuring strategy is implemented using the same equipment at all production facilities. Measuring programs can be exchanged between factories, where only the user interface needs to be adapted to the respective local languages.

At the same time, the devices serve as a quasi early warning system. Kiekert can detect right away if the parts are still ok or if certain measures need to be taken. This enables the company to seek dialogue with suppliers immediately and implement measures in a targeted way.

Bettina Brandt added: “When selecting a measuring system, it was especially important to us that users are able to operate the device without having any specialised knowledge in the area. It should be as easy to operate as a gauge.” This approach is reflected in the user interface of the PC-DMIS Vision measuring software. It‘s designed to guide the user through the measurement process solidly and reliably. Photos visualise how parts have to be clamped on the measuring device, for example.

The Optiv Classic devices are so flexible that it was even possible to integrate a bar code scanner into the process. The operator scans the code of the incoming part, and the appropriate measuring program starts up automatically.

A results converter turns the measurement data into Excel files. This makes the results comparable and transparent. A warning system immediately forwards measurement results lying outside the tolerance range to the responsible quality personnel for complaint processing.

The “doormen“ at Kiekert are rising to the occasion. Their job remains the same: Ensuring absolutely secure locks, in every Kiekert factory, in any situation.

Kiekert AG is the world‘s leading supplier of high-quality locking system technology for the automotive industry. With development and production locations across the globe, the locking system specialist is locally accessible to customers in every major automotive region of the world. The company‘s particular focus on high-quality product development is mirrored in their modern product range. Over a third of their technologies are less than three years old and make Kiekert the world‘s number-one provider of sidedoor locking systems. The same high quality standards apply at every Kiekert production location – it‘s what the company‘s international customers expect.

At first glance, a car lock seems like a trivial thing. Global Laboratory Manager Bettina Brandt puts things into perspective: “A lock is quite comparable to a Swiss watch. Between 70 and 125 individual parts interlock with and engage one another. Deviations in the hundredth of a millimetre range in a single part can result in lock malfunction.” Ultimately, every Kiekert lock has to lock reliably and open just as reliably. This is ensured thanks to the high standard of quality in every area of the business.

Getting a handle on the supply flow

The supply flow is also complex. 350 suppliers provide the Kiekert factories with 5,000 different parts, mainly punched parts, precision punched parts and injectionmoulded parts made of plastic. For example, one million individual parts are delivered to the factory in the Czech Republic, Kiekert‘s largest factory, on a daily basis. How do you get a handle on this kind of nearly inconceivable flow of goods?Klaus Hense, Senior Manager of Global Supplier Quality, explained: “Naturally, we conduct advance quality planning with our suppliers, carry out audits and have put best practices in place. Without a filter in our incoming goods department, there would always be a risk of a defective part slipping through. We continuously develop and refine our incoming goods inspection to keep it up to date.”

A few years ago, each factory still developed its own methodology for incoming goods inspection. The factory in Mexico, for example, produced expensive, typebound gauge sets for each vendor part. Since costs tended to continue rising, attempts were made to find another solution.

Since 2012, Kiekert have been using a globally uniform, measuring, documenting and assessable solution, the Optiv Classic 321 GL multi-Sensor measuring systems from Hexagon Metrology, which are compatible with the latest standards and with every vendor part. These change-friendly systems enable Kiekert to keep up with the dynamics of the automotive market and its frequent model changes.

Global concept implemented locally

In the meantime, all Kiekert factories have been outfitted with identical CNC-controlled 3D measuring machines. This ensures that the measuring strategy is implemented using the same equipment at all production facilities. Measuring programs can be exchanged between factories, where only the user interface needs to be adapted to the respective local languages.At the same time, the devices serve as a quasi early warning system. Kiekert can detect right away if the parts are still ok or if certain measures need to be taken. This enables the company to seek dialogue with suppliers immediately and implement measures in a targeted way.

Bettina Brandt added: “When selecting a measuring system, it was especially important to us that users are able to operate the device without having any specialised knowledge in the area. It should be as easy to operate as a gauge.” This approach is reflected in the user interface of the PC-DMIS Vision measuring software. It‘s designed to guide the user through the measurement process solidly and reliably. Photos visualise how parts have to be clamped on the measuring device, for example.

The Optiv Classic devices are so flexible that it was even possible to integrate a bar code scanner into the process. The operator scans the code of the incoming part, and the appropriate measuring program starts up automatically.

A results converter turns the measurement data into Excel files. This makes the results comparable and transparent. A warning system immediately forwards measurement results lying outside the tolerance range to the responsible quality personnel for complaint processing.

More than just a gauge

The universal incoming goods inspection concept will also be exported to Russia in the near future, where the newest Kiekert factory is being built. “Naturally, the potential of Optiv machines exceeds the functionality of a gauge. They can be fitted with tactile and optical sensors, for example,” confirmed Klaus Hense. “As soon as we get the new location up and running, I can well imagine that we‘ll be using the devices in Russia for initial sampling and problem analysis, in addition to incoming goods inspection.”The “doormen“ at Kiekert are rising to the occasion. Their job remains the same: Ensuring absolutely secure locks, in every Kiekert factory, in any situation.