Measuring under challenging conditions

WeserWind GmbH – Germany

Contact us

Quality and dimensional accuracy are the be-all and end-all of offshore wind turbine manufacturing, because individual system components are assembled on the open sea. Offshore deployment of staff and installation ships is costly and expenses must be kept as low as possible.

Offshore wind turbines are installed out at sea, often in water depths of up to 50 m. The stresses of wind and waves are transferred to the seabed through the foundation structures. Large wind turbines in deeper waters are founded on several base points, for example by using tripods. Tripods are manufactured from large-sized steel tubes and form a stable three-legged base. With the help of Hexagon’s coordinate measuring device DPA, the offshore construction company WeserWind ensures the dimensional accuracy of its tripods, which can reach heights of approximately 60 m and weights of up to 960 t.

WeserWind GmbH is part of Georgsmarienhütte Holding GmbH (GMH) and produces large-scale steel structures in Bremerhaven. In addition to various individual structures for offshore wind farms such as transformer stations and their foundation structures, the company focuses on the serial production of foundation structures. Prefabrication is carried out in the two production facilities on a former shipyard in Bremerhaven, while the final assembly of complex steel structures is done in a hall specially built for serial production with a height of 45 m and a length of 180 m.

With these resources, WeserWind operates the world’s only facility for serial production of tripods. In 2013 WeserWind delivered its 100th tripod and established itself as a competent and reliable partner in the challenging environment of steel structures.

Innovative metrology meets massive structures

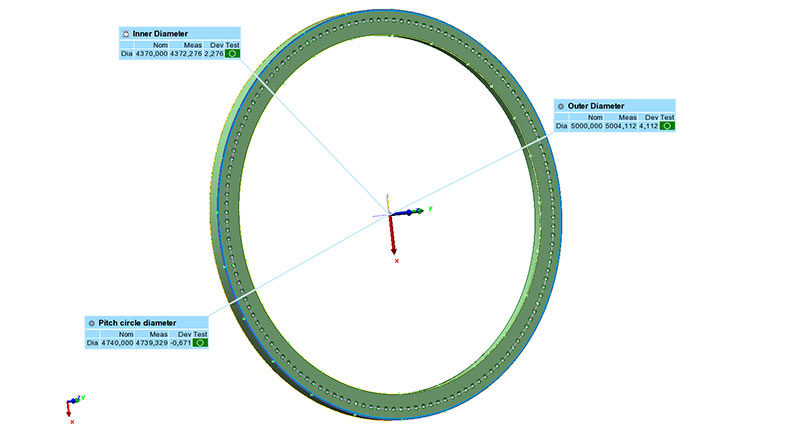

The mobile 3D measurement system DPA has been successfully used by WeserWind since 2011. Measurement tasks include the inclination of the flange plane, hole pattern of the flange, ovality of the flange and angle of the head and foot braces. This enables early detection and adjustment of deviations before completion, ensuring the reliability of subsequent assembly processes at high sea.

The measurement work is done at a height of 55 to 60 m under difficult conditions: high altitudes, strong winds, unstable subsoils. No problem for DPA! The measuring system is lightweight and portable, and therefore also suitable for working in extraordinary production or testing environments. The DPA can show off its skills where laser trackers or tachymeters capitulate!

First, the measurement object is signalized with targets or measuring adapters at relevant geometric points. The object is photographed from different directions with the digital camera, so that all significant areas are covered. The digital images are processed in the evaluation computer and the 3D coordinates of the signaled geometry points are automatically calculated. The average measurement of a flange, including signaling, image acquisition and automated report generation, takes less than an hour.

First, the measurement object is signalized with targets or measuring adapters at relevant geometric points. The object is photographed from different directions with the digital camera, so that all significant areas are covered. The digital images are processed in the evaluation computer and the 3D coordinates of the signaled geometry points are automatically calculated. The average measurement of a flange, including signaling, image acquisition and automated report generation, takes less than an hour.

The measurements are carried out by the industrial surveyors Technologiekontor Bremerhaven (TKB) on behalf of WeserWind. Together with the Hexagon support engineers, WeserWind and TKB have developed a measurement concept for tripods. Hexagon offers special adapters to simply measure the geometric elements, such as the drilling pattern. What’s more, Hexagon has developed an automated test sequence with report creation. The DPA-measuring system is extremely flexible and is also used for other measuring tasks, such as roundness measurement, CAD comparison, deformation analysis and welding distortions.

A project (FKZ: 0325054) funded by the German Federal Ministry for the Environment (BMU) included an analysis of 3D measurement technology applications. After first tests with a tachymeter, photogrammetry and laser tracker, WeserWind opted for the portable 3D measuring system DPA. Project Manager Remo Pelzer of WeserWind explains the reasons for choosing Hexagon: “In our daily work we deal with very large components that must be manufactured and assembled under tight tolerances. A suitable measurement system must not only be able to achieve maximum accuracy, but on top of that must be able to meet extreme environmental conditions in production and at sea. No other measurement system offers these capabilities in combination with great versatility and mobility.”

We give thanks to the WeserWind GmbH in Bremerhaven (Germany) for the friendly support.

Offshore wind turbines are installed out at sea, often in water depths of up to 50 m. The stresses of wind and waves are transferred to the seabed through the foundation structures. Large wind turbines in deeper waters are founded on several base points, for example by using tripods. Tripods are manufactured from large-sized steel tubes and form a stable three-legged base. With the help of Hexagon’s coordinate measuring device DPA, the offshore construction company WeserWind ensures the dimensional accuracy of its tripods, which can reach heights of approximately 60 m and weights of up to 960 t.

Challenging offshore projects for sustainable success

Challenging offshore projects for sustainable success

WeserWind GmbH is part of Georgsmarienhütte Holding GmbH (GMH) and produces large-scale steel structures in Bremerhaven. In addition to various individual structures for offshore wind farms such as transformer stations and their foundation structures, the company focuses on the serial production of foundation structures. Prefabrication is carried out in the two production facilities on a former shipyard in Bremerhaven, while the final assembly of complex steel structures is done in a hall specially built for serial production with a height of 45 m and a length of 180 m.

With these resources, WeserWind operates the world’s only facility for serial production of tripods. In 2013 WeserWind delivered its 100th tripod and established itself as a competent and reliable partner in the challenging environment of steel structures.

Innovative metrology meets massive structures

The mobile 3D measurement system DPA has been successfully used by WeserWind since 2011. Measurement tasks include the inclination of the flange plane, hole pattern of the flange, ovality of the flange and angle of the head and foot braces. This enables early detection and adjustment of deviations before completion, ensuring the reliability of subsequent assembly processes at high sea.

The measurement work is done at a height of 55 to 60 m under difficult conditions: high altitudes, strong winds, unstable subsoils. No problem for DPA! The measuring system is lightweight and portable, and therefore also suitable for working in extraordinary production or testing environments. The DPA can show off its skills where laser trackers or tachymeters capitulate!

First, the measurement object is signalized with targets or measuring adapters at relevant geometric points. The object is photographed from different directions with the digital camera, so that all significant areas are covered. The digital images are processed in the evaluation computer and the 3D coordinates of the signaled geometry points are automatically calculated. The average measurement of a flange, including signaling, image acquisition and automated report generation, takes less than an hour.

First, the measurement object is signalized with targets or measuring adapters at relevant geometric points. The object is photographed from different directions with the digital camera, so that all significant areas are covered. The digital images are processed in the evaluation computer and the 3D coordinates of the signaled geometry points are automatically calculated. The average measurement of a flange, including signaling, image acquisition and automated report generation, takes less than an hour.The measurements are carried out by the industrial surveyors Technologiekontor Bremerhaven (TKB) on behalf of WeserWind. Together with the Hexagon support engineers, WeserWind and TKB have developed a measurement concept for tripods. Hexagon offers special adapters to simply measure the geometric elements, such as the drilling pattern. What’s more, Hexagon has developed an automated test sequence with report creation. The DPA-measuring system is extremely flexible and is also used for other measuring tasks, such as roundness measurement, CAD comparison, deformation analysis and welding distortions.

DPA meets all requirements

DPA meets all requirements

A project (FKZ: 0325054) funded by the German Federal Ministry for the Environment (BMU) included an analysis of 3D measurement technology applications. After first tests with a tachymeter, photogrammetry and laser tracker, WeserWind opted for the portable 3D measuring system DPA. Project Manager Remo Pelzer of WeserWind explains the reasons for choosing Hexagon: “In our daily work we deal with very large components that must be manufactured and assembled under tight tolerances. A suitable measurement system must not only be able to achieve maximum accuracy, but on top of that must be able to meet extreme environmental conditions in production and at sea. No other measurement system offers these capabilities in combination with great versatility and mobility.”We give thanks to the WeserWind GmbH in Bremerhaven (Germany) for the friendly support.