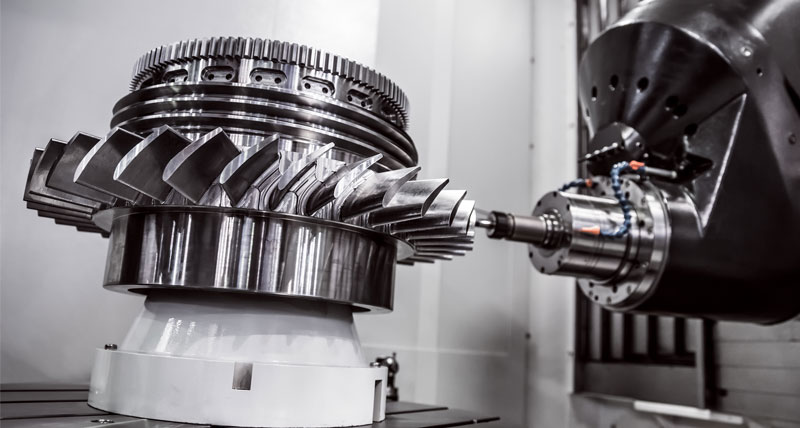

Machine tool probing for aero engine fan casings

On-machine inspection solutions for aero engine fan casing measurement

Contact us

Fan cases are a critical component of aircraft safety. These turbofan components must be produced to the highest quality to ensure they aren’t penetrated by debris in the event of fan blade damage and to bear the subsequent load imbalance.

Fan cases are expensive components, both in terms of their material and production processes. As such, if any mistakes found in inspection lead to scrap, this would be very costly. Machine tool probing, on the other hand, enables manufacturers to inspect in between machining steps.

The inner surface of a fan case has very tight tolerances to ensure the most efficient clearance between the fan blade leading edge and the casing. Hexagon’s on-machine probing allows the fan casing to remain on the machine until the close tolerances have been achieved, saving time in transporting the part and machining costs. By enabling early identification of machining effects like tooling and chipping, these machine tool probing solutions drive greater precision in the quality assurance of key fan casing characteristics like cylindricity and flanged ends.

As well as generating collision-free inspection paths, Hexagon’s software solutions deliver closed loop control of fan case machining, enabling manufacturers to compare in real time the contours from the CAD design file with the actual dimensions of the fan case while it is on in the machine.

Our solutions

Explore Hexagon solutions for machine tool probing for fan casing machining