Aero engine spools and shafts inspection

Dimensional measurement solutions for quality assurance of aero engine spools and shafts

Contact us

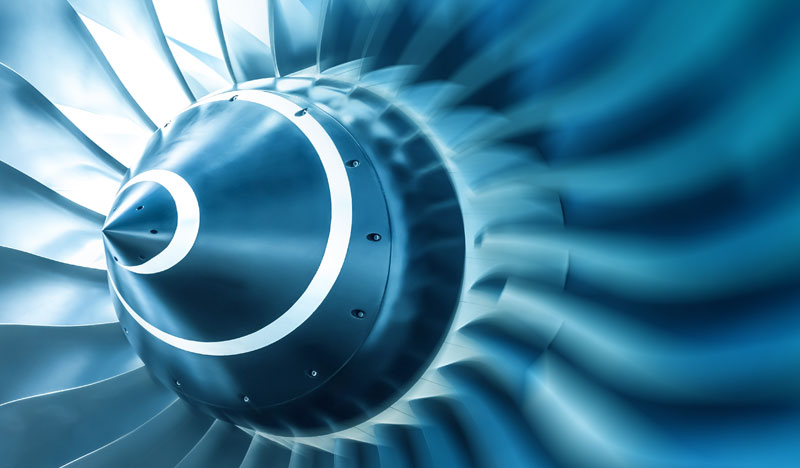

Shafts and spools are at the core of the aero engine, transmitting power created by the turbines to drive the compressor. As such, high-accuracy measurement of these components is required to ensure the efficient and safe operation of the turbofan.

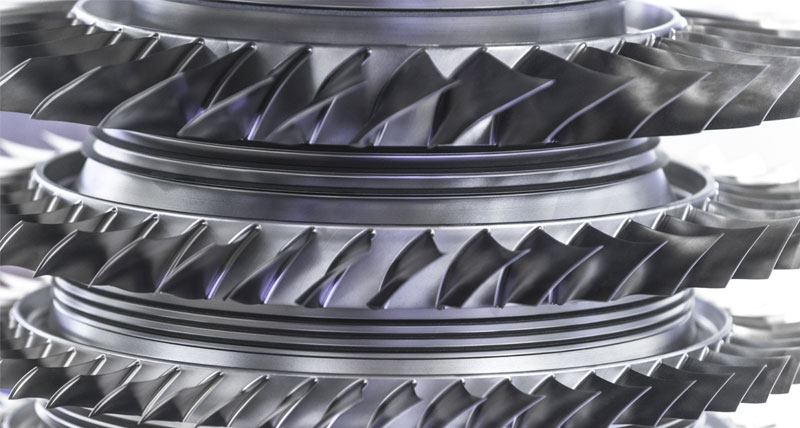

Since spools and shafts operate at high rotational speeds, any imbalance in the positive locking joints will cause significant vibration, leading to accelerated wear and ultimately engine failure. Likewise, the alignment and geometries of splines need to meet tight tolerances to protect the teeth from wear and ensure smooth rotation and transmission. Aero engine spools are often fitted with multiple rows of blades, requiring precise measurement to capture their profiles. Spools and shafts are large, one-piece assemblies, which can make rejects costly, so it’s necessary to have measurement solutions that can quickly capture the entire length and circularity of the part and enable prompt remedial action when required.

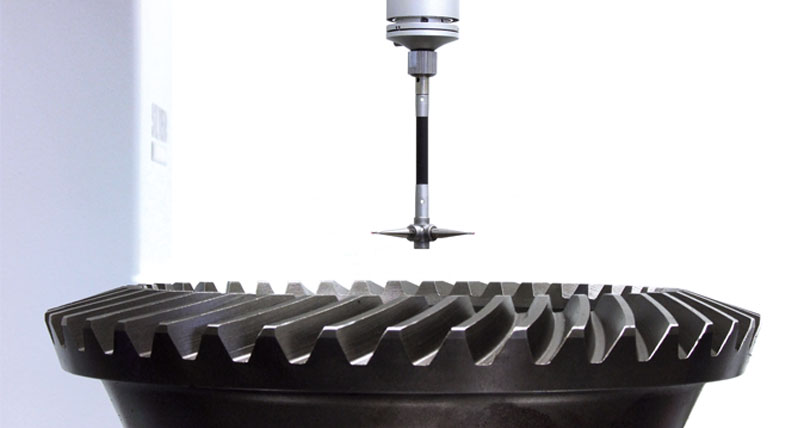

Hexagon offers 3D coordinate measuring machine (CMM) solutions that offer the accuracy and flexibility required to measure large aero engine spools and shafts. Gear features are captured with a highly precise tactile scanning probe, supporting accuracy demands in the submicron range. 4-axis scanning capability increases access to difficult-to-reach drum features and shortens the measuring cycle. Specialised software offers user-friendly programming and automated measurement of the variety of geometries that will be encountered in spools and shafts, from the multiple cylindricity requirements of the part such as coaxiality and concentricity tolerancing.

Our solutions

Explore Hexagon solutions for aeroengine spool and shaft inspectionUltra-High Accuracy CMMs

Achieve the precision and accessibility required for smaller shaft and spool inspection with the 4-axis scanning of the Leitz PMM-C and SP-S2 Scan+ probe.

Large-Volume CMMs

Combine excellent part accessibility for bigger shafts and spools with minimised uncertainty using the DELTA SLANT gantry CMM.

Versatile Metrology Software

The parametrised measurement programming of QUINDOS is ideally suited to the variety of measuring tasks involved in spools and shafts inspection.