Asahi Intecc utilises simulation to develop delivery devices that carry markers to the vicinity of cancers more efficiently

Asahi Intecc Co., Ltd. is using the nonlinear structural analysis software, Marc, to develop delivery devices that carry markers to the vicinity of cancers in preparation for endoscopic surgery, having introduced the MSCOne software licensing system to enable its engineers to easily access Computer Aided Engineering (CAE) products from MSC Software, part of Hexagon’s Manufacturing Intelligence division.

Asahi Intecc, based in the city of Seto, in Japan, manufactures ‘minimally invasive treatment’ products that help to keep operation wounds as small as possible, and minimise pain. This contributes to the patients’ overall quality of life and leads to early discharge from hospital, reducing medical expenses.

As an R&D-focussed company, Asahi Intecc mainly develops and manufactures products that are used in medical devices that are indispensable for catheter treatment, such as guide wires, using unique technologies that have been created through the process of responding to the advanced needs of its customers.

Asahi Intecc's products have been developed based on its medium-term management plans of 'Strategic development of the global market and expansion of affected / treatment areas' and 'Creation of new businesses in global niche market'. As a result, there's an increasing need to create and establish previously unexplored functions and structures. As such, it’s important for the Company to ensure that the direction of design is correct at the initial phase, and to employ agile development processes so that its team can bring new value to the market at the earliest possible time.

The company invested in OneMSC in 2020, which is a flexible licensing system that allows the Company to access any Computer Aided Engineering (CAE) software they need from the Hexagon portfolio. They use Marc to understand how the endoscopic delivery device will deform when subjected to forces within the body. Through MSCOne, they also use the visualisation capabilities of the Cradle scFLOW software to generate high-quality polyhedral mesh elements and to construct complicated models.

The latest CT scanning technology makes it cheaper and easier for cancer to be detected when it is still extremely small. But even if CT scans pick up signs of cancer on some organs, especially the lungs, it may be difficult to pinpoint its exact location during surgery, and that’s where Marc helped.

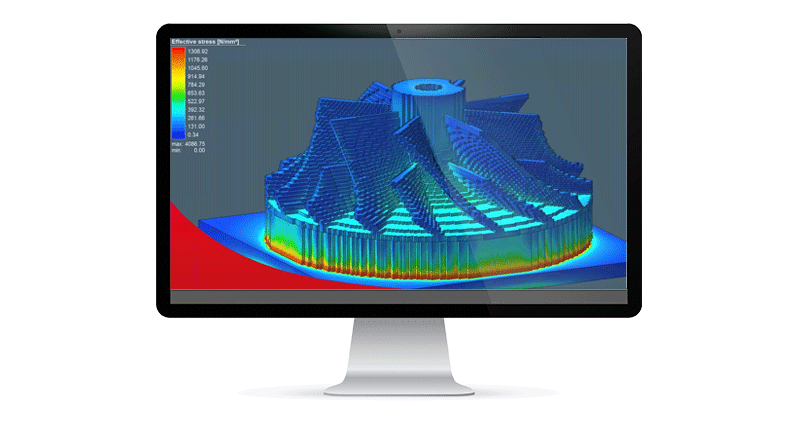

Marc is a powerful, general-purpose, nonlinear finite element analysis solution that accurately simulates the device’s behaviour under static, dynamic and multi-physics loading scenarios. Its versatility in modelling nonlinear material behaviours and transient environmental conditions makes it ideal to help Asahi Intecc design a delivery system to place a marker near the cancer.

A coiled wire known as a retaining fin, is attached to the marker. The marker is carried to the cancer site by the delivery device, with the retaining fin housed in a dedicated cylinder, and ejected at its destination. The fins are then deployed into their original coiled shape, attaching themselves to the organ, placing the marker there.

The deployment of the retaining fins is very fast, so it is usually difficult to see with the naked eye, and the initial value of deployment differs depending on the stored state. As such, the opening pattern varies, making it difficult to verify that a design works as intended.

The Asahi Intecc team has been able to resolve this issue, and visualise how the spring coils will be stored and deployed – even taking large deformations into account – by using numerical analysis with Marc to help develop the delivery device. This gives them the ability to verify the behaviour of the mooring fin will when implemented in different surroundings, and greatly improves their development efficiency.

Senior Researcher at Asahi Intecc, Hiroyuki Aiba, says “Marc’s advanced analysis makes it possible to confirm at the idea stage how the new structure will accurately perform, before taking the traditional steps of trial production and experimentation. It promotes fresher ideas and highlights manufacturing risks.”

They are also currently considering using MSCOne to advance fluid analyses with Cradle scFLOW. “This software makes it possible to find the highest performing structures at an early stage of the design process; again, an effective way of improving the efficiency of how a product is developed, and getting it to market quickly.”

The company made decision to invest in MSCOne after sample analysis from a number of vendors and feedback about them. It was attracted by Marc’s analysis, Hexagon’s consulting ability, and the fact that MSCOne gives them access to analysis software that can be used across a wide range of complex areas.

Having experienced the convenience of MSCOne, the Company is looking forward to developing other products in Asahi Intecc’s extensive medical portfolio using the Hexagon CAE portfolio.