VISI Reverse

The shortcut from 3D scan to manufacturing

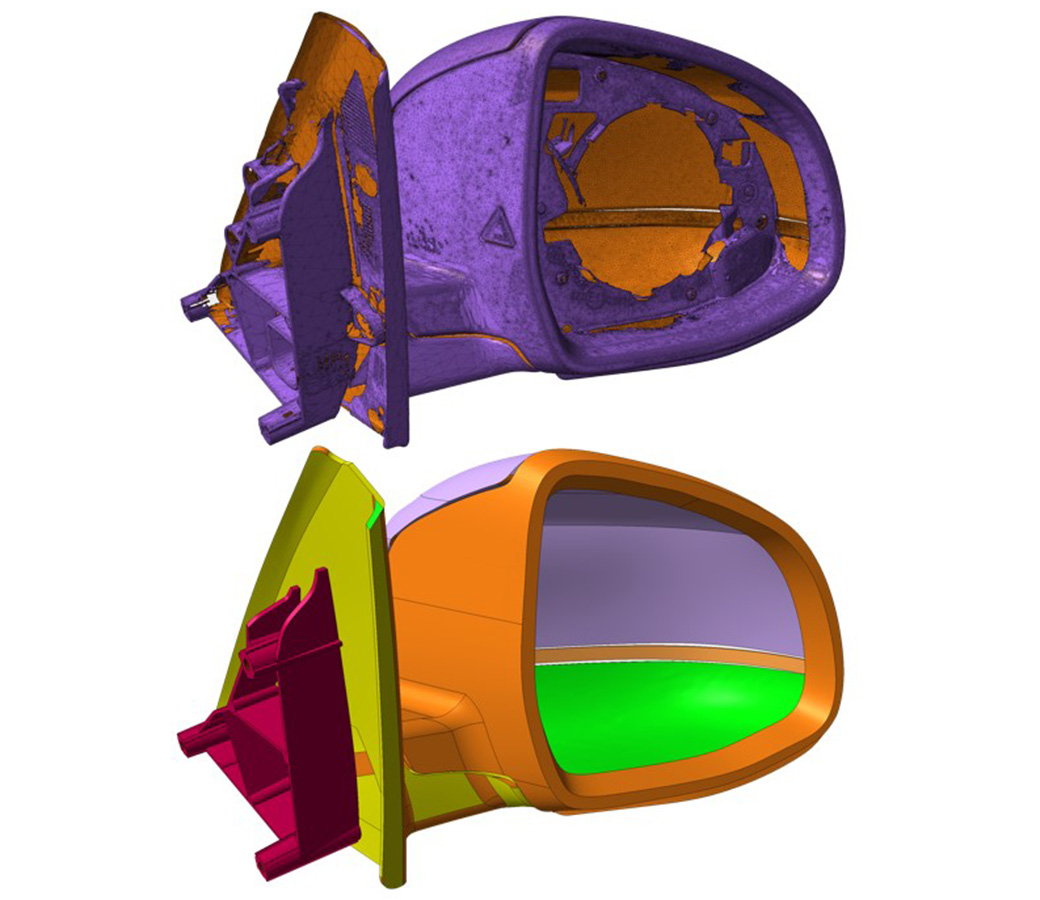

Editable models from scan data

VISI Reverse combines hybrid modelling CAD functionality with 3D scan data processing abilities.

Ready to learn more?

Product capabilities

Features at a glance:

- Direct import of point cloud from scanning device

- Automatic mesh creation / cleaning / smoothing

- Dynamic wireframe grid construction

- Automatic surface creation

Modelling your thoughts

Real world challenges require real world solutions. VISI Reverse allows you to create editable CAD models from 3D scanned data and integrate them into our Mold or Stamping Die workflow.

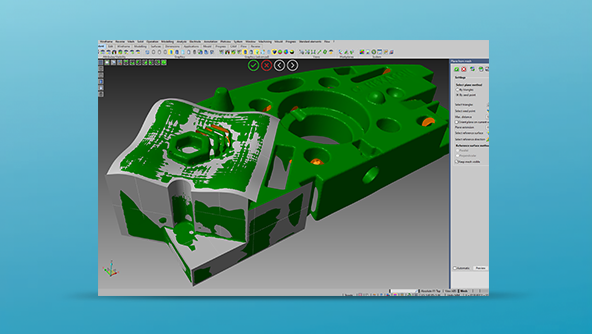

Saving time to design

Reconstructing geometrical object from point data, adjusting and correcting the model with CAD commands, defining punches, die plates and create the tool could take you weeks, but thanks to the intuitive, semi-automatic and complete array of functions offered in VISI Reverse you can shorten considerably the time required to complete your manufacturing process.

Leverage your past

The success of the future lays its foundation on the past, so many projects are inspired by existing ones. Easily scan your prototype, existing models into VISI, adapt and improve it. With VISI Reverse any new project can start from a tangible object.

Manufacturing the real world

Using VISI Reverse you can design and customize components which are perfectly adapted with the existing products. Recreate broken or worn part, create replacement parts, design new model revisions are just some of the many applications of this new VISI module.

Powerful and flexible

VISI Reverse is born to import unlimited scanned data directly from Hexagon portable devices such as the Absolute Arm or the Leica Absolute tracker, or from a generic CSV file format and to convert these data point clouds into a usable mesh, a fully editable geometrical model or a hybrid model.VISI Reverse comes loaded with point cloud filtering, processing and optimizing tools, mesh editing, refining and smoothing algorithms, and with many different semi-automatic functions to create surfaces that will fit the original 3D scan data. With VISI Reverse, you can scan your world, re-design and manufacture… all in one system.

Portable measuring arms and 3D laser scanners

Hexagon Manufacturing Intelligence provides industrial metrology systems for when dimensional measurement matters. 3D digital capture of shapes and surfaces using lasers is an effortless and precise process. Portable scanning allows you to take measurements directly in the manufacturing environment, where process improvements are the most beneficial.Portable measuring arms and 3D laser scanners

Hexagon Manufacturing Intelligence provides industrial metrology systems for when dimensional measurement matters. 3D digital capture of shapes and surfaces using lasers is an effortless and precise process. Portable scanning allows you to take measurements directly in the manufacturing environment, where process improvements are the most beneficial.