Romax Spectrum

Romax Spectrum enables full system powertrain NVH simulation, from gear and electric machine design through to vehicle sound quality, so that you can develop high quality products faster, with reduced reliance on physical prototyping.

Want to learn more?

Romax: Integrated powertrain simulation

Romax Spectrum is part of the Romax portfolio, an integrated toolset for ePowertrain engineering from concept exploration to virtual product sign-off.

The challenge

Modern powertrain design places great challenges on the NVH engineer: Make it quiet without compromising durability or efficiency while simultaneously accelerating the development process and reducing development costs. New noise environments for ePowertrains (higher rotation speeds and no engine masking of gear and motor noise) along with new vehicle and powertrain architectures mean that NVH must be considered thoroughout development from concept to final optimisation so that problems can be ironed out through simualtion alone before they become real.

The solution

Successful design for NVH requires a combination of accurate, trusted simulation plus the ability to consider dynamic behaviour from the earliest design phase. When this is rolled into a workflow that is optimised for simulation speed and efficiency, you are empowered to simulate and optimise your design to create high quality products faster and with less prototyping, testing and troubleshooting.

Overview

Romax Spectrum meets the challenges of today’s powertrain NVH development processes, providing fast, easy to interpret answers which allow in-depth analysis, problem resolution and optimisation of noise and vibration caused by gears and motors.

Rapid design

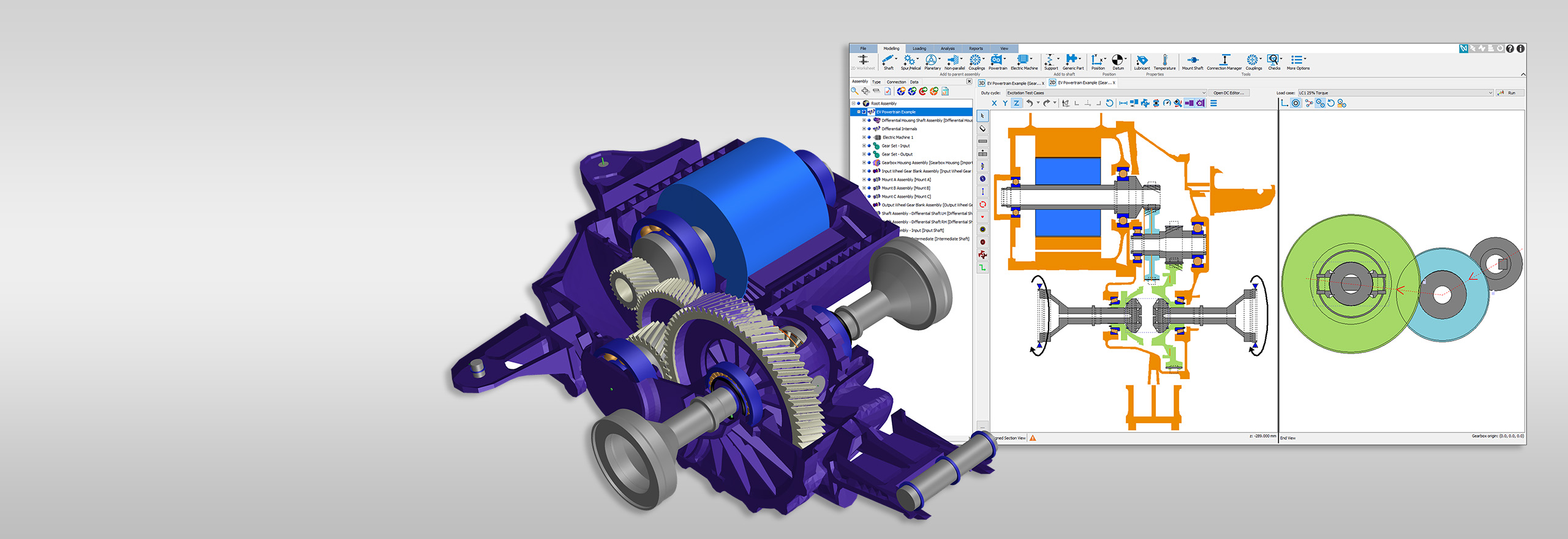

Build parametric models of any full drive system rapidly (in minutes), with an easy-to-use drag-and-drop 2D modelling interface and a live reflection of the model in 3D visualisation. Models (starting with basic shaft, gear, bearing arrangements) can be created from scratch, imported from other Romax products, from CAD geometry, or via a number of other interfaces such as REXS.

- Romax offers multi-fidelity component models across the full system:

- Model helical, spur and planetary gears as loading (ratio only), concept (teeth/module defined), detailed (macro/micro geometry)

- Model bearings initially as linear stiffnesses, then select from comprehensive bearing catalogs or design a custom bearing

- Import/create and condense FE components (or import from FEA), and model flexible FE bearings and gear blanks

Models can then be converted to MBD, CAD, CFD and other formats to save time on data re-entry.

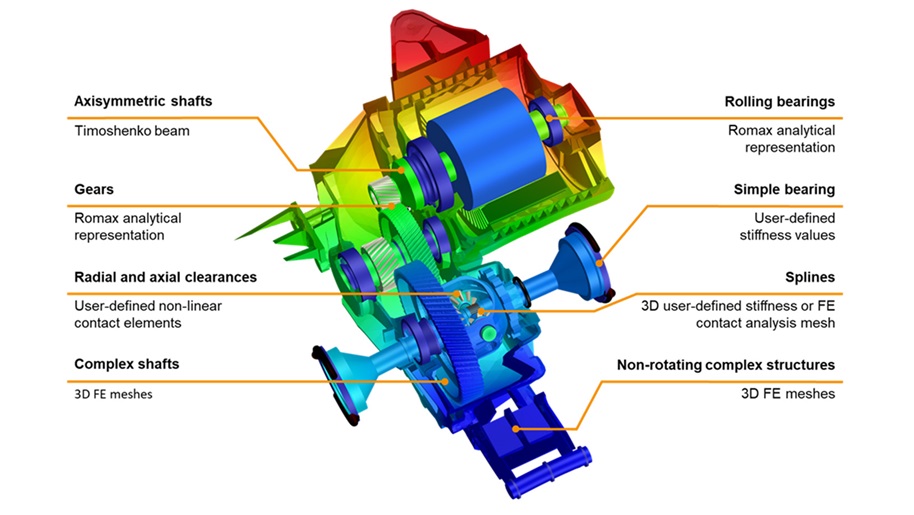

Combining state of the art gear and bearing contact models with the latest standards and stress-based life calculations, Romax offers fast, proven prediction of component performance and full-system structural deformations. Romax’ holistic approach to system simulation considers the cumulative effect of the complex interactions between all components:

- shaft deflections

- gear misalignments and shifting contacts

- housing flexibility

- non-linear, load-dependent bearing stiffness

- component stresses and loads

Analyses are appropriate to model fidelity, ranging from fast approximations when evaluating design concepts to more detailed analyses during virtual testing and design for manufacture. Thanks to its hybrid approach of FE, analytical and empirical methods, Romax is able to provide this analysis very quickly. The most computationally-efficient and accurate method is used for each part, and combined into a fully-coupled system simulation that provides the optimal blend of speed and accuracy, specifically designed for powertrain simulation.

Thanks to its fast yet accurate frequency domain analysis approach, Romax Spectrum is well-suited for NVH investigations throughout development, starting from the early design stages.

You can use the validated analysis approach of Romax Spectrum to predict gear and electric machine noise and vibration performance and make engineering decisions with confidence. Considering the NVH performance early and often during development means that you can identify and prevent problems through simulation before they become problems in the real world, giving you higher quality products with less prototyping.

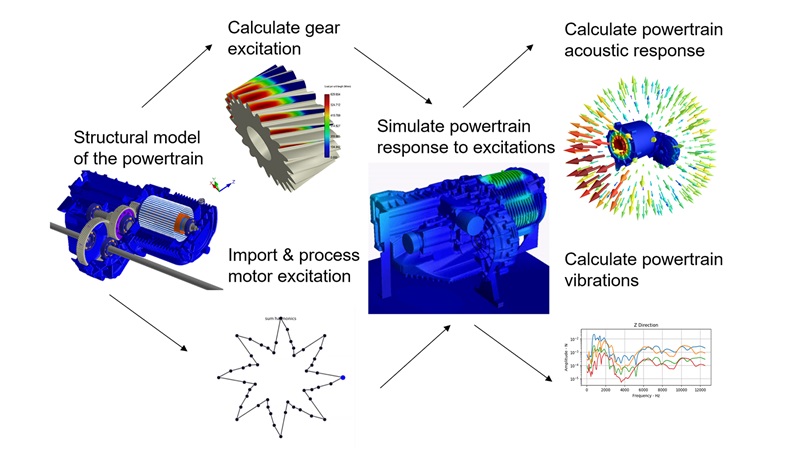

- Excitations: validated analysis to predict dynamic gear excitations, including unique planetary gear simulation, and links to electromagnetic software to calculate motor forces.

- System vibration – Frequency domain simulation of system vibration response giving you instant access to the answers you need along with the engineering insight into how to make your design better

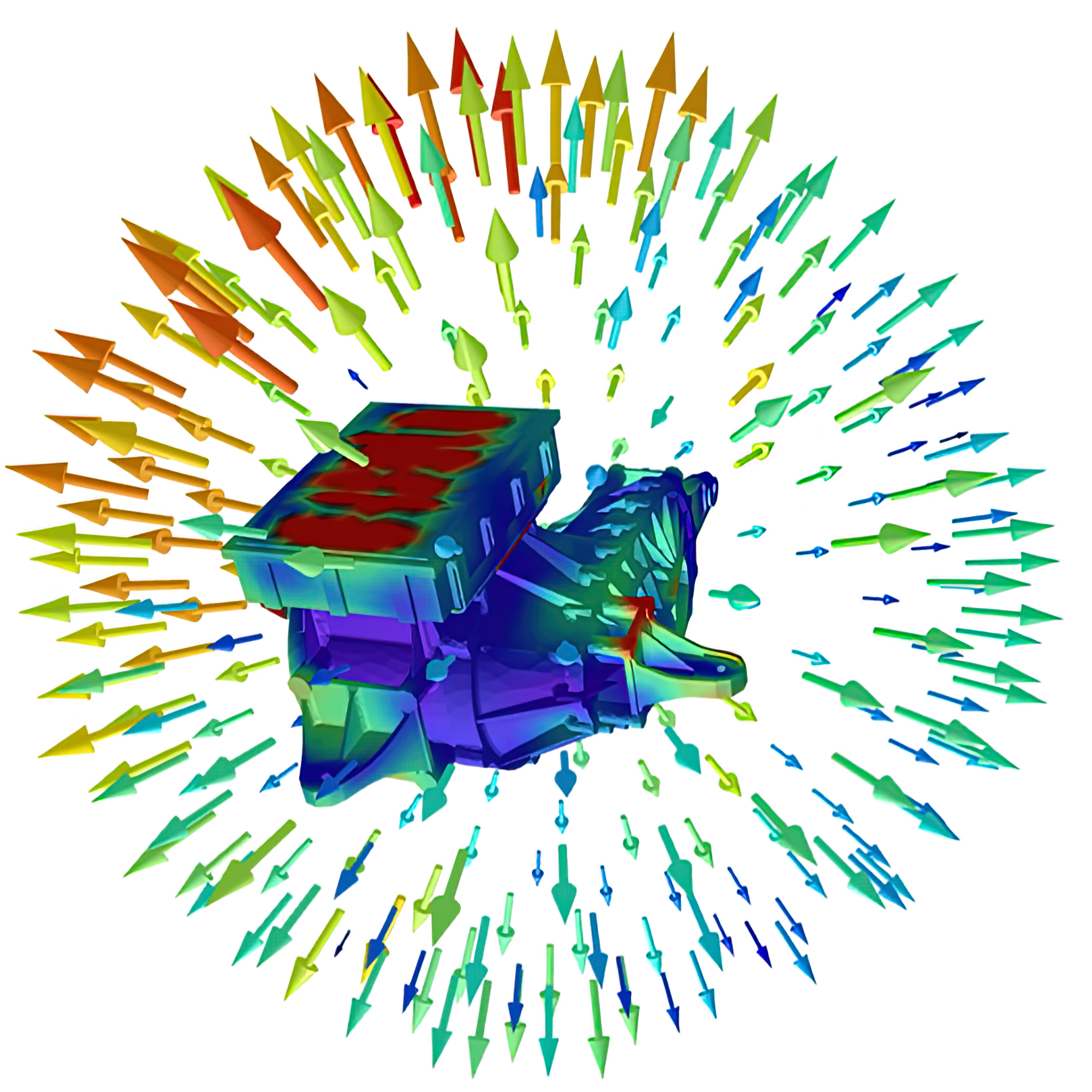

- Radiated noise – Embedded acoustic solver brings complex simulation to the non-expert with automated calculations to see if your design meets its noise targets

Romax Spectrum Acoustic Analysis adds radiated noise capabilities to the vibration simulation and analysis provided by Romax Spectrum to give you a thorough understanding of NVH performance in electro-mechanical powertrains.

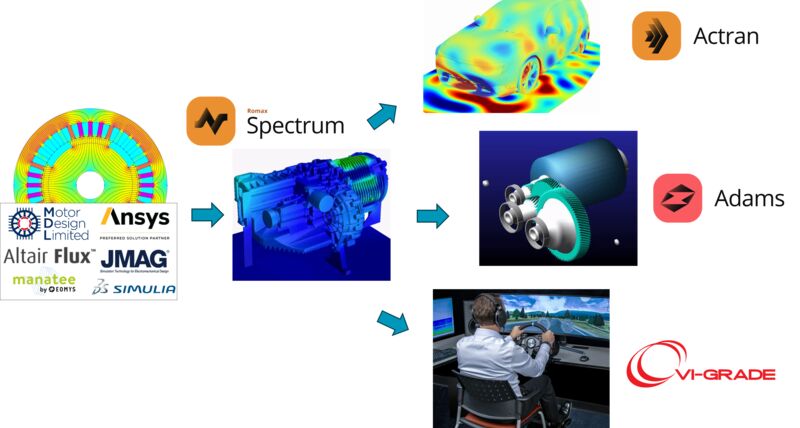

Based on renowned and trusted meshing and solver technology from Actran, Romax Spectrum’s Acoustic Analysis product option forms a complete end-to-end process which allows you to predict radiated noise quickly and simply, without any in-depth experience of acoustic simulation. In combination with Romax Spectrum’s vibration prediction and system dynamic analysis tools, you can identify and mitigate the root causes of radiated noise problems in a single software product.

For acoustic experts, Romax Spectrum’s interface to Actran means you can explore and optimize noise performance further and in more detail.

Integrated ePowertrain design

Romax Spectrum is part of the Romax portfolio, which means you can use the same model in common file formats for multi-attribute, multi-fidelity, full system design, simulation and optimization. Our product range starts with Romax Concept, the perfect platform for early stage investigation and design space exploration, and extends through Romax Enduro, Romax Spectrum and Romax Energy, for analysis and optimization of efficiency, durability and NVH within a single model. Romax Spin adds world-leading bearing design and analysis capabilities, while Romax Evolve provides the perfect tool for electric machine designers looking to test out the structural and NVH performance of their motor.

Beyond Romax, we have interfaces with dozens of other tools in the Hexagon portfolio and beyond. So, whether you are wanting to take your Romax powertrain into a full vehicle MBD model in Adams, or import electromagnetic loss data to be considered in the efficiency prediction of your electric machine, Romax will sit at the heart of your workflow.

-

Case studies

-

Webinars

-

White papers