Romax Enduro

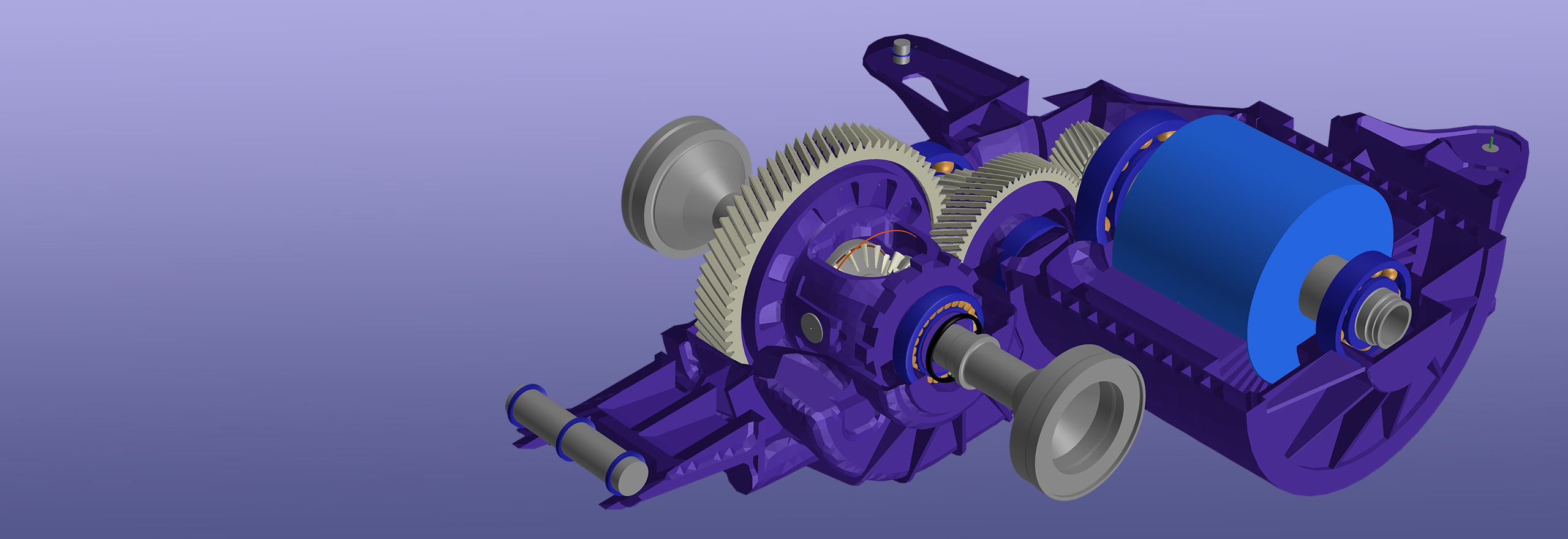

Part of the Romax toolset, Romax Enduro offers fast and easy modelling, detailed system-level structural simulation, state of the art component rating and advanced gear and spline analysis for powertrain durability design and optimisation. With Enduro, powertrain engineers and gear designers can design durable and robust geared electro-mechanical systems.

Want to learn more?

Romax: Integrated powertrain simulation

Romax Enduro is part of the Romax portfolio, an integrated toolset for ePowertrain engineering from concept exploration to virtual product sign-off.

The challenge

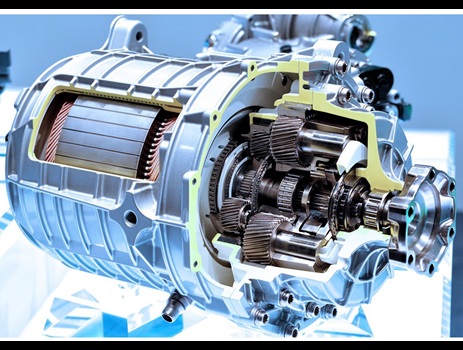

Durability has always been a key driveline performance target. The shift towards electric is driving demand for new transmission architectures across numerous vehicle platforms, when subject matter expertise is at a premium. Conducting thorough analysis early can help engineers optimise transmission durability, while minimising prototyping and reducing time to market and manufacturing costs.

The solution

Romax Enduro is a sophisticated, yet easy to use structural design, analysis and optimisation solution for the development of Right First Time, durable electro-mechanical drivetrain systems. Validated time and again by customers and research projects, Romax Enduro is the trusted solution for durability analysis across multiple industries.

Overview

Romax Enduro enables powertrain engineers to:

- Quickly assess system and component loads, deflections and misalignments and size and refine the drivetrain layout

- Calculate component ratings over duty cycles according to common engineering standards such as ISO 6336, ISO 281, ISO/TS 16281

- Perform detailed stress analysis on components such as loaded tooth contact analysis (LTCA) and root stress analysis and optimise details like micro-geometry while accounting for manufacturing

- Run parametric studies to find optimum designs, assess sensitivity and predict robustness to manufacturing variability

- Drive the simulation model from an external application through a command line interface

- Collaborate with peers internally and externally, who may use different tools, while maintaining data accuracy with ease through various import and export options

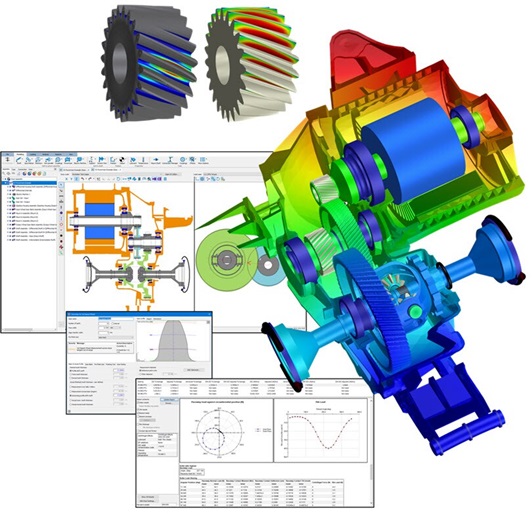

Rapid design

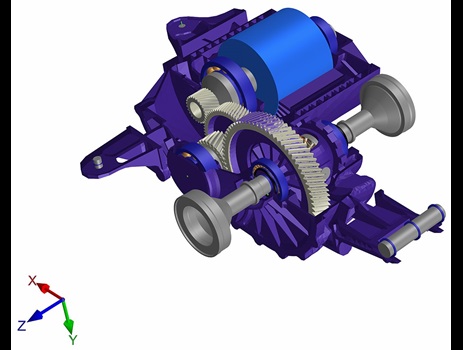

Build parametric models of any full drive system rapidly (in minutes), with an easy-to-use drag-and-drop 2D modelling interface and a live reflection of the model in 3D. Models (starting with basic shaft, gear, bearing arrangements) can be created from scratch, imported from other Romax products, from CAD geometry, or via a number of other interfaces such as REXS.

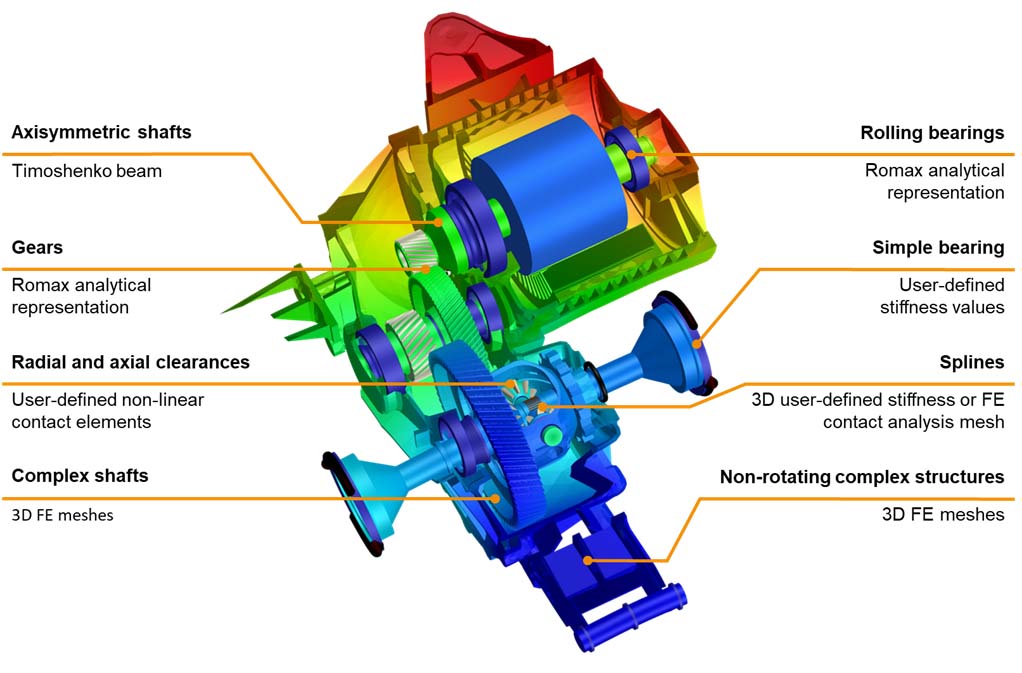

- Romax offers multi-fidelity component models across the full system:

- Model helical, spur and planetary gears as loading (ratio only), concept (teeth/module defined), detailed (macro/micro geometry)

- Model bearings initially as linear stiffnesses, then select from comprehensive bearing catalogs or design a custom bearing

- Import/create and condense FE components (or import from FEA), and model flexible FE bearings and gear blanks

Models can then be converted to MBD, CAD, CFD and other formats to save time on data re-entry.

Combining state of the art gear and bearing contact models with the latest standards and stress-based life calculations, Romax offers fast, proven prediction of component performance and full-system structural deformations. Romax’ holistic approach to system simulation considers the cumulative effect of the complex interactions between all components:

- Shaft deflections

- Gear misalignments and shifting contacts

- Housing flexibility

- Non-linear, load-dependent bearing stiffness

- Component stresses and loads

Analyses are appropriate to model fidelity, ranging from fast approximations when evaluating design concepts to more detailed analyses during virtual testing and design for manufacture. Thanks to its hybrid approach of FE, analytical and empirical methods, Romax is able to provide this analysis very quickly. The most computationally-efficient and accurate method is used for each part, and combined into a fully-coupled system simulation that provides the optimal blend of speed and accuracy, specifically designed for powertrain simulation.

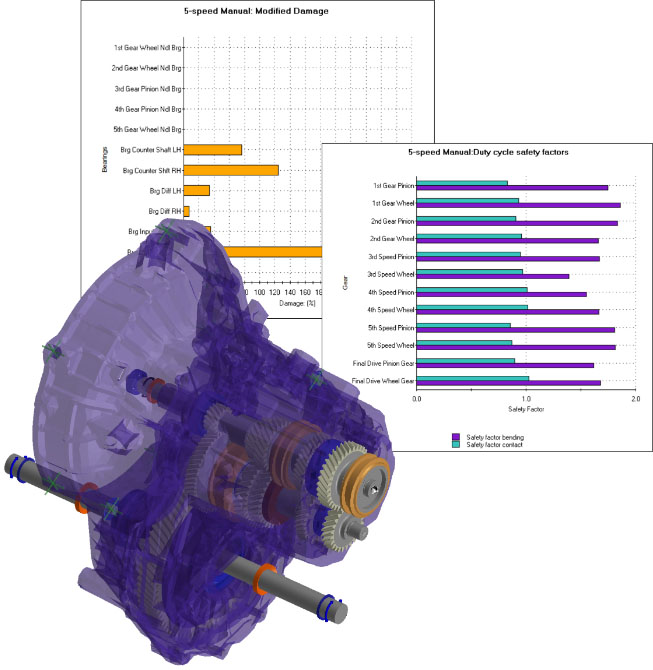

Perform durability analysis at a component or full-system level, including:

DIN, ISO and AGMA rating (gear contact and bending, micro-pitting, scuffing, gear tooth flank fracture, bearing life, shaft fatigue, spline rating).

- Bearing durability: proven, independent models for rolling element bearing stiffness and durability, including flexible FE bearing rings, and detailed hydrodynamic journal bearing analysis, including profile modifications, grooves and holes.

- Synchroniser sizing

- Duty cycles generation from measured data

- Effect of manufacturing tolerances

- Detailed gear and spline contact results

- Load case and duty cycle durability reports

Build up gear designs to suitable levels of fidelity: loading gears, for fast design iteration of ratios and layouts and calculation of system loads without needing detailed geometry; concept gears, for selection of module and tooth number combinations; and detailed gears, with full macro- and micro-geometry parameters.

Micro geometry can be defined from typical design inputs such as crowning, slope, tip relief, etc., or specified as an arbitrary grid, or imported from measurements using the Gear Data Exchange (GDE) format from metrology systems such as QUINDOS, or generated from a gear finishing simulation utilising powerful manufacturing simulation from Dontyne Systems.

Gear analyses capabilities include:

- Calculate contact loads, contact stresses, load lines, flash temperature, transmission error

- Analyse gear micro geometry

- Analyse gear root stress

- Consider virtual gear manufacturing through interfaces to gear design and manufacturing software for accurate geometry import and contact analysis

Romax Enduro offers various optimisation processes and variability analyses, for high quality, robust design.

- Perform full factorial, Monte Carlo, Sensitivity, genetic optimisation, and custom studies

- Optimise gear geometry, component preload, or any other parameter in the entire model

- Study variability within tolerances and component performance over a very large number of cases and duty cycles

- Understand the design space and create optimised and robust designs

Romax’s XML batch interface enables control of Romax processes through the command line or via automation with external applications such as Excel, Matlab, Python, modeFRONTIER, Isight, Optimus, HEEDS etc.

Reporting can also be automated utilising customisable templates, making it easy to robustly generate the required results in the desired format as part of an automated process.

Integrated ePowertrain design

Romax Enduro is part of the Romax portfolio, which means you can use the same model in common file formats for multi-attribute, multi-fidelity, full system design, simulation and optimization. Our product range starts with Romax Concept, the perfect platform for early stage investigation and design space exploration, and extends through Romax Enduro, Romax Spectrum and Romax Energy, for analysis and optimization of efficiency, durability and NVH within a single model. Romax Spin adds world-leading bearing design and analysis capabilities, while Romax Evolve provides the perfect tool for electric machine designers looking to test out the structural and NVH performance of their motor.

Beyond Romax, we have interfaces with dozens of other tools in the Hexagon portfolio and beyond. So, whether you are wanting to take your Romax powertrain into a full vehicle MBD model in Adams, or import electromagnetic loss data to be considered in the efficiency prediction of your electric machine, Romax will sit at the heart of your workflow.

-

Case studies

-

Webinars

-

White papers