Q-DAS destra | Statistical Package

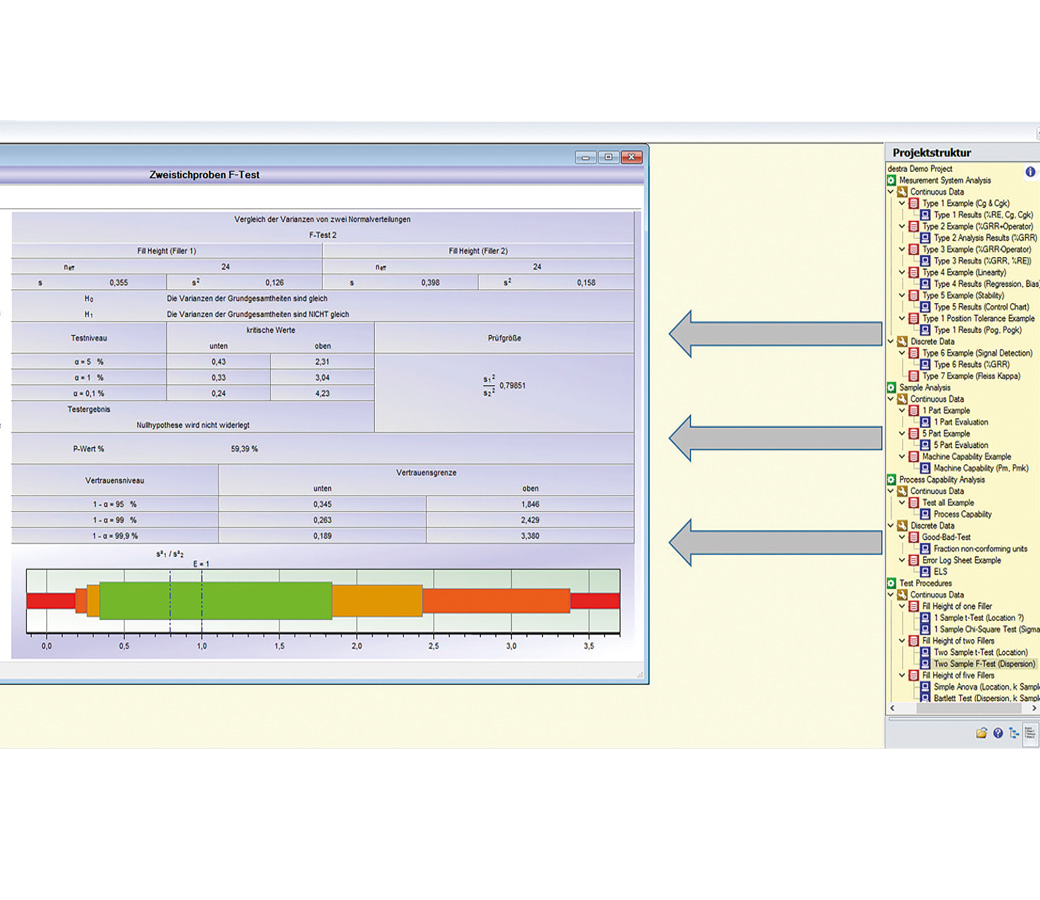

Process improvement is the deliberate optimisation of available process conditions and destra provides you with a rich set of statistical methods in order to do so. Statistical procedures test the statistical significance of different relations. Destra also supports the application of simple statistical methods for process improvement, so-called Shainin methods.

Process optimisation

Statistical package for process optimisation and process improvement by means of statistical tests and Shainin methods.

Ready to learn more?

Reliability study

destra helps users to plan lifetime analyses, evaluate data collected in an experiment and show the results in graphics. It is a solution for comprehensive data analysis in acceptance and new development projects in industry.Product capabilities

Reliability check

Reliability analyses check whether a product meets its requirements under specific conditions over time.

- End-of-life test

- Censoring (type I, type II and hybrid censoring schemes)

- Sudden death test

- Eckel procedure for field failure

- Success run tests.

Design of experiments is a tool for analysing cause-and-effect relationships between factors and responses, and for optimising products and processes. A well-structured acquisition of data plays a major role.

- Intuitive user interface to create individual experimental designs

- Appealing and significant graphics of results

- Optimisation of several responses.

The analysis of variance and regression supports you in adapting mathematical models to cause-and-effect relationships between factors and responses.

- Excellent model designs

- Various designs for analysis of variance

- Formula editor

- Mixed effects

- Hierarchically nested models

- Unbalanced data

- Visual model diagnostics

- Cook’s distance, leverage values and residuals.

A machine capability analysis provides evidence that the machines are able to produce specified product characteristics with required accuracy. After starting the process, operators measure further parts; these measurement results form the basis for preliminary process capability. In long-term process analysis, process results are illustrated based on distribution time models which in turn help to calculate short-term and long-term capabilities and to select suitable quality control charts.

- Best suitable distribution time model

- Quality control charts

- Evaluation of results.

Process analysis is based on statistical evaluations of characteristic values. The measurement process records these values. In order to avoid misinterpretations, the recorded measured values have to reflect the real situation with reasonable certainty. Various procedures and methods help to assess whether the measurement process is suitable for the intended purpose.

Extensions:

-

Form Designer

-

Serial interfaces

-

Q-DM Datamanagement