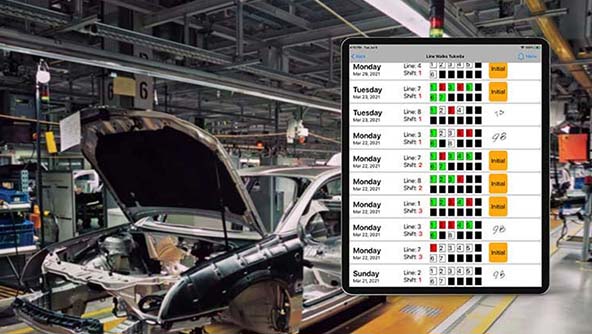

Nexus Connected Worker Audits

Maximise output and equipment performance with user-friendly digital audits, visual guidance, and autonomous maintenance tracking for seamless production line transitions and maintenance management.

Enhance efficiency and safety

Ensures safe machinery and optimal output through operator-friendly digital audits, visual guidance, and data utilisation

Enhancing efficiency and safety through user-friendly digital audits

Connected Worker Audits streamline operations by ensuring machinery safety and maximising output through user-friendly digital audits, visual guidance, and data utilisation. Capabilities like Line Clearance, Autonomous Maintenance Tracking, and Pre-Shift Inspection empower operators to efficiently prepare production lines during transitions or changeovers while enhancing equipment performance. Workers can independently manage and monitor maintenance tasks, thereby maintaining quality and operational integrity through thorough assessments of equipment and processes at the close of each work shift.