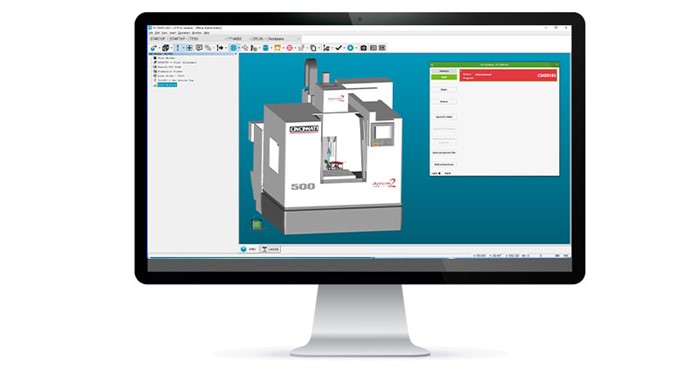

PC-DMIS NC

PC-DMIS NC – Metrology software for CNC machines

Ready to get started?

Reduce scrap and rework

PC-DMIS NC software products are advanced, in-process metrology systems for CNC machines. They simplify the job of writing inspection routines for NC machines but do not compromise on the sophisticated programming, measurement, evaluation and reporting tools of the baseline product.

PC-DMIS NC products gives you the tools to reduce scrap by selectively measuring subgroups of features during setup and periodically during production. They can monitor CNC performance and ferret out faults associated with things like programming errors, bad setups and excessive tool wear. They also give you the information you need to evaluate how your machines are performing over time. With their built-in analytical capabilities, PC-DMIS NC products have the ability to quickly spot problems on a particular feature and immediately alert you.

The time spent setting up jobs and aligning parts and fixtures doesn't add value to a manufacturing process. PC-DMIS NC products lets you do these tasks quickly and easily. It simplifies the jobs of setup and alignment, reducing the need for manual inspection.

Because PC-DMIS NC software products are part of the Enterprise Metrology Solutions (EMS) System, they give you access to software like DataPage+, our SPC package that lets you statistically monitor the performance of equipment. In day-to-day operations, you may run into all sorts of problems related to CNC operations. PC-DMIS NC products coupled with EMS gives you access to a software system with the capabilities to work though difficulties and get on with the job of making parts. Measuring extremely large parts, qualifying raw castings and calculating complex alignments that were either extremely difficult or impossible now become straightforward programming tasks.