scSTREAM | HeatDesigner

Fastest and easiest CFD software for electronics and architecture

Ready to learn more?

Overview:

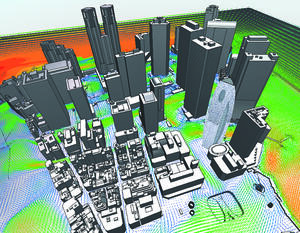

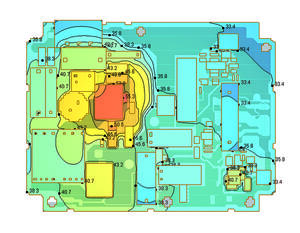

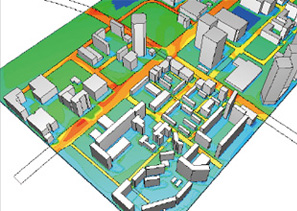

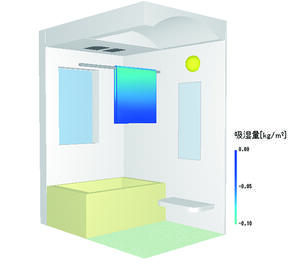

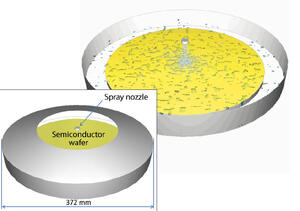

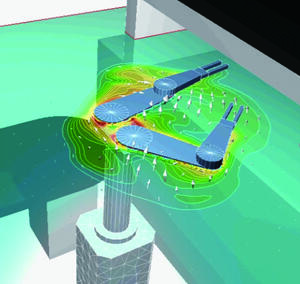

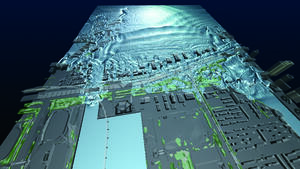

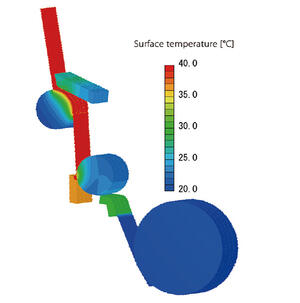

scSTREAM is a general-purpose CFD tool that uses Cartesian or cylindrical structured mesh to enable easy mesh generation and high-speed simulations to be performed in a fraction of the time. Due to the meshing nature and analysis system that enables large-scale calculation, scSTREAM works best at processing extensive simulations, where users are required to solve thermal problems of electronic devices and indoor environment, wind flow, and heat island phenomena.

Software Features

For more details on the latest version, please visit Cradle CFD Support Home Page

-

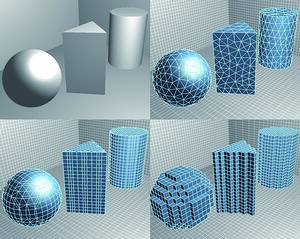

Various methods to represent shapes

-

Large-scale calculation

-

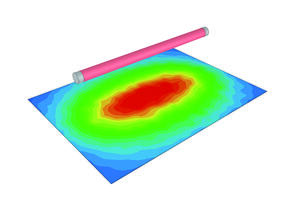

Radiation

-

Reading wiring patterns

-

Solar radiation (ASHRAE, NEDO)

-

Humidity / dew condensation

-

Particle tracking

-

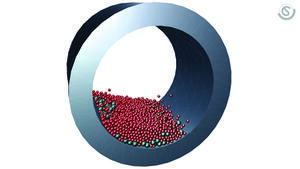

Discrete element method (DEM)

-

Moving objects

-

Free surface

-

Thermal comfort, heat stress risk and ventilation efficiency indices

-

Panel (heat conduction / transfer / thermal transport)

Learn more about Cradle CFD products and services at www.cradle-cfd.com