ESPRIT EDGE

Revolutionize your manufacturing operations with true digital twin technology, artificial intelligence, next generation automation tools, and robust CAM programming to safely and efficiently drive all of your CNC machinery.

CAM for CNC Machine tool Programming

Powered by Artificial Intelligence and driven with Digital Twin technology

Product

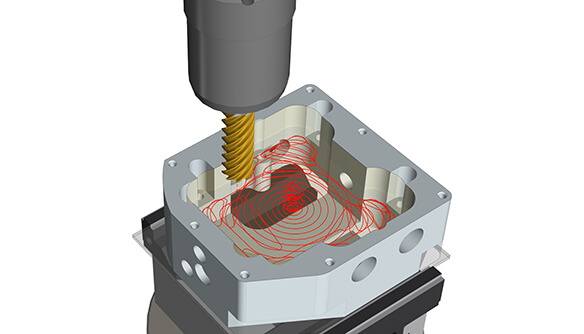

Milling 3- to 5-Axis

ESPRIT EDGE provides a comprehensive suite of milling cycles that can be utilized on CNC machines of any range.

Product

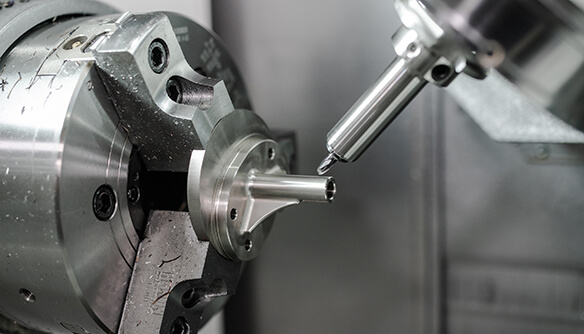

Turning and Millturn

ESPRIT EDGE offers versatile turning and part handling cycles for all types of CNC lathes or millturn machines and integrates milling, turning, and probing operations into a single program.

Product

Wire EDM

Tailored solutions are available for different wire EDM brands and machines, optimizing performance by leveraging machine-specific knowledge to set ideal cutting conditions.

Product

High-Speed Machining

ESPRIT EDGE offers high-speed machining cycles for 2.5-, 3-, 4-, and 5-axis roughing that yield benefits like reducing cycle times and extending tool life.

Product

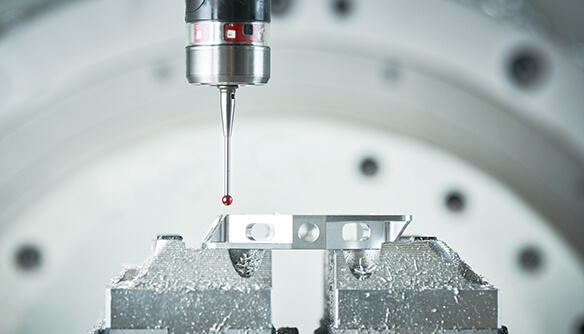

On-Machine Inspection

On Machine inspection capability helps streamlining the entire process by combining machining and inspection capabilities into a single program.

Product

Metal Additive Manufacturing

The software enables simultaneous programming for both additive and subtractive processes, facilitating a natural workflow for both hybrid and dedicated additive machines.

Product

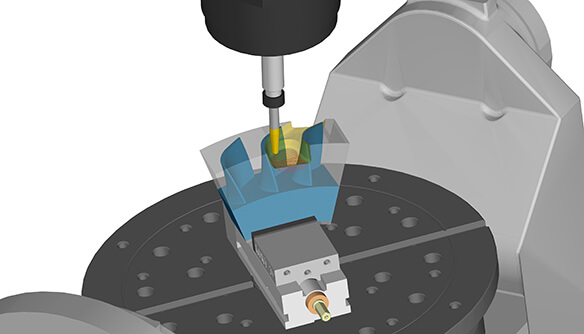

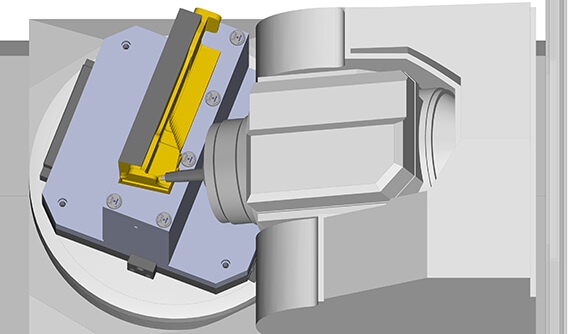

Virtual Machine Setup

ESPRIT EDGE's digital twin incorporates machine models, controller emulators, machine parameters, and post processors, enabling precise simulation and the generation of machine-optimized G-code.

Product

Turn-key Post Processing

With turnkey post processors, you can visualize the entire machining process and machine environment in dynamic, solid-shaded graphics including the machine kinematics.