m&h LS-R-4.8 Radio laser scanner for machine tools

The wireless laser scanner that works automatically with a tool changer

Would you like to know more?

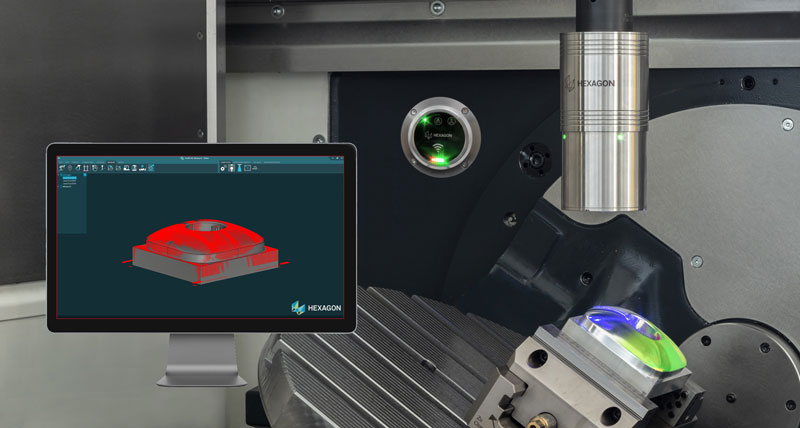

The m&h LS-R-4.8 is a wireless laser scanner for machine tools. Data is transmitted via radio to the machine control and measuring software, which is why the sensor can be changed in and out of the tool changer without any manual steps.

Accurate machine tool measurement typically involves capturing data for a limited number of points on a part. With a metrology-grade laser scanner integrated into the machine tool, users can quickly capture and analyse a complete, data-rich image of a part and act to address flaws while the part is still clamped. The results bring new levels of speed, precision and flexibility to machine tool inspection, while minimising the need for external measurement devices.

Equipped with a blue line laser, the m&h LS-R-4.8 quickly and precisely captures data equally well on shiny or dark surfaces. The design is optimised for the harsh environment in machine tools and the large field of view is ideal to capture all relevant areas of a clamped part.

In combination with the radio receiver m&h RC-R-100, the laser scanner can be used flexibly and is fully automated. In addition, other Hexagon sensors and machine tool probes can be integrated into the production process.

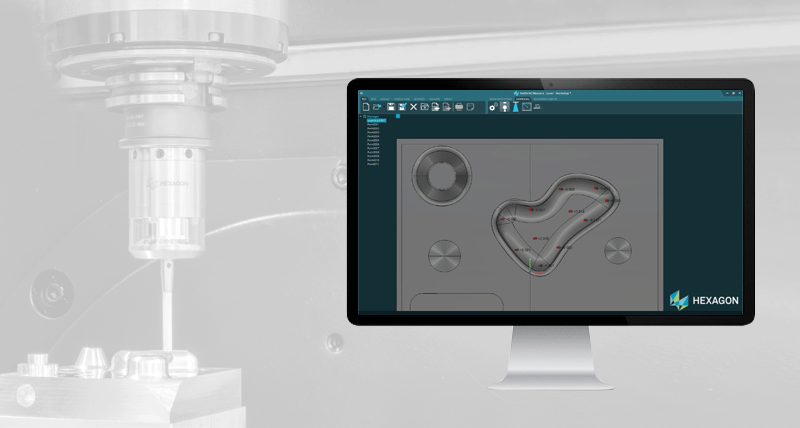

Its intuitive, highly functional software is compatible with controls from Fanuc, Siemens and Heidenhain and supports measurements with up to 5 axes.

Accurate machine tool measurement typically involves capturing data for a limited number of points on a part. With a metrology-grade laser scanner integrated into the machine tool, users can quickly capture and analyse a complete, data-rich image of a part and act to address flaws while the part is still clamped. The results bring new levels of speed, precision and flexibility to machine tool inspection, while minimising the need for external measurement devices.

Equipped with a blue line laser, the m&h LS-R-4.8 quickly and precisely captures data equally well on shiny or dark surfaces. The design is optimised for the harsh environment in machine tools and the large field of view is ideal to capture all relevant areas of a clamped part.

In combination with the radio receiver m&h RC-R-100, the laser scanner can be used flexibly and is fully automated. In addition, other Hexagon sensors and machine tool probes can be integrated into the production process.

Its intuitive, highly functional software is compatible with controls from Fanuc, Siemens and Heidenhain and supports measurements with up to 5 axes.

-

Downloads

-

Features & benefits

-

Related information

-

Technical data

Buy Machine Tool accessories online

Identify your spare parts with confidence and benefit from fast UPS delivery

About Machine Tool Measurement

Measuring on the machine tool, whether for workpiece inspection, temperature or tool control, is a valuable source of information in the machining process.

m&h RC-R-100 Radio receiver

The radio receiver m&h RC-R-100 communicates with radio-wave touch probes in the 2.4 GHz range and can be easily mounted in the machine room.

HxGN NC Measure

Highly versatile and easy to use, HxGN NC Measure modular software simplifies the inspection of a wide range of parts directly on the machine tool.