Materials lifecycle management for aerospace

Solutions to capture and manage data about materials from integrated processes throughout the aerospace product lifecycle

Contact us

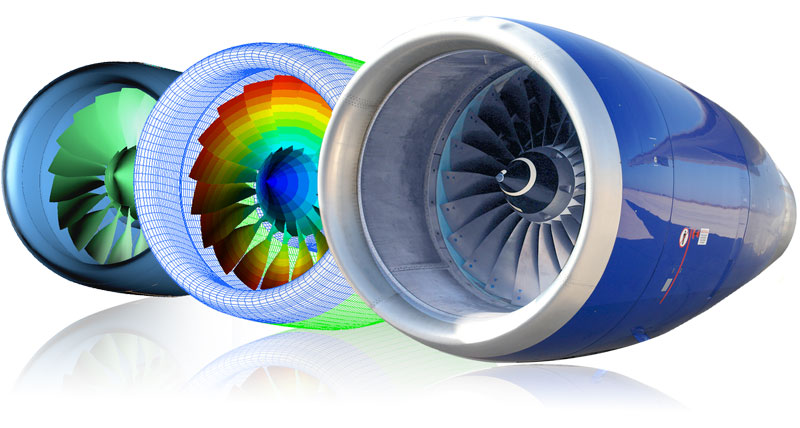

Aerospace manufacturers and OEMs generate enormous amounts of data about the materials they use when manufacturing aircraft parts.

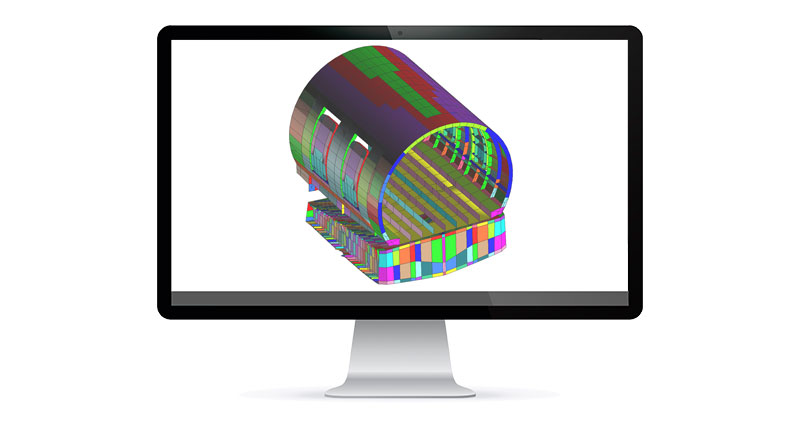

Design and engineering teams can draw on this valuable information to make sure they are using the right materials during simulation, thereby saving time. Being able to track material use is crucial, especially given the growing use of complex, lighter, high-performance advanced metals and composites, which enable manufacturers to meet regulatory requirements such as reductions in CO2 emissions. Not only does the right data mean engineers avoid mistakes, they can also use it to drive product innovation in alloys, elastomers, plastics, and composites for aerospace industry use.

Materials data also increases traceability and lets manufacturers prove to regulatory bodies they are using a consistent source of approved materials, derived from traceable integrated processes. But the ability of aircraft manufacturers and OEMs to automatically access data about materials depends on how well they manage it.

Hexagon’s materials lifecycle management solutions link materials specialists to mechanical simulations systems. And it captures data from integrated processes to ensure full traceability across the business and the product lifecycle.

Our solutions

Explore Hexagon solutions for materials lifecycle management in the aerospace industry

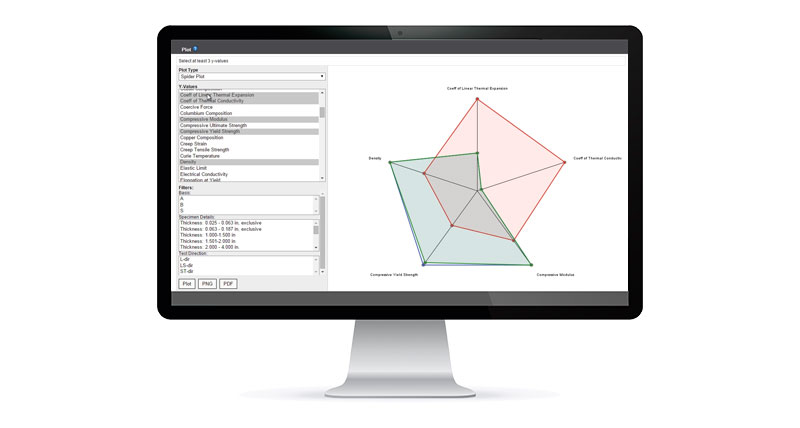

Material data management software

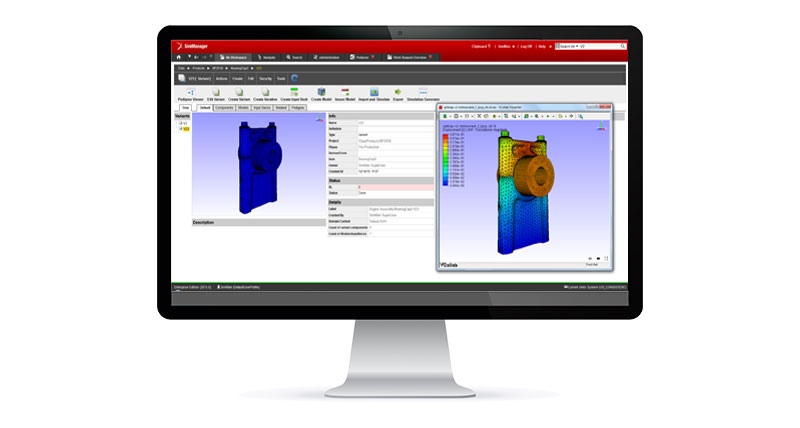

Simulation data management software

Case studies

Read customer stories about using CAE in the aerospace industry.