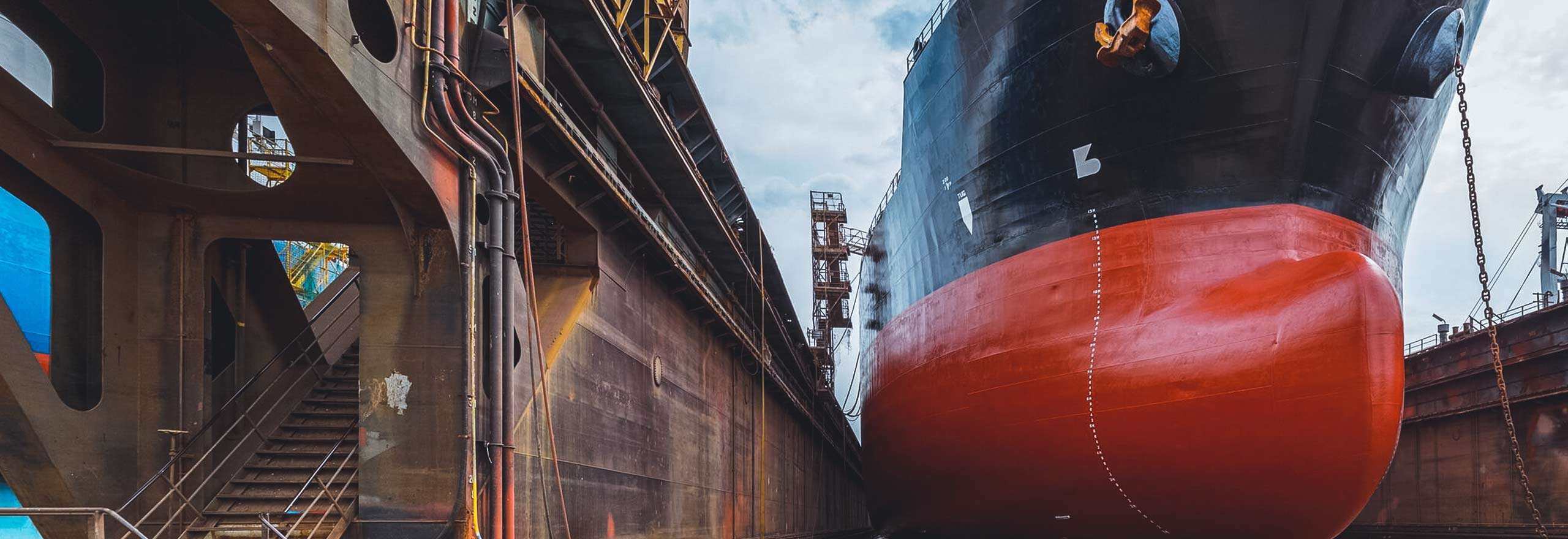

How Hexagon creates value for shipbuilding industry

Launching shipbuilding into an era of data-driven performance

Many shipbuilding operations exist in silos. A lack of integration between disciplines and no end-to-end visualization of processes can creates countless errors. Hexagon is unleashing the power of data to improve cost, schedule and resource accuracy to improve overall performance.

Opportunity in the wake of disruption

Investing in these technologies will fundamentally transform every stage of the project lifecycle. Traditionally siloed project stages become single integrated systems, from design and planning through fabrication, construction and commissioning, all benefiting from information exchange in almost real-time.

Harnessing data to propel innovation

Recent upheavals and global uncertainty have shown the importance of digital transformation in the shipbuilding industry. Gains here deliver proven results, as does the use of digital twin models to improve design and project execution before, during and after construction.

Further, shipbuilders are also expected to decrease greenhouse gas emissions related to their activities. Increasing operational agility and automation will also help builders make their operations more environmentally friendly while containing costs and maintaining profitability.

With solutions from Hexagon that address the entire project lifecycle, shipbuilders can:

- Compress schedule and control budget

- Minimise rework with efficient resource planning

- Eliminate wasted material and overruns

- Enhance quality management

- Streamline processes and improve transparency

- Access the right information at the right time