Key stakeholders of the automotive industry

Hexagon helps OEMs, big tech and more drive their digital journey

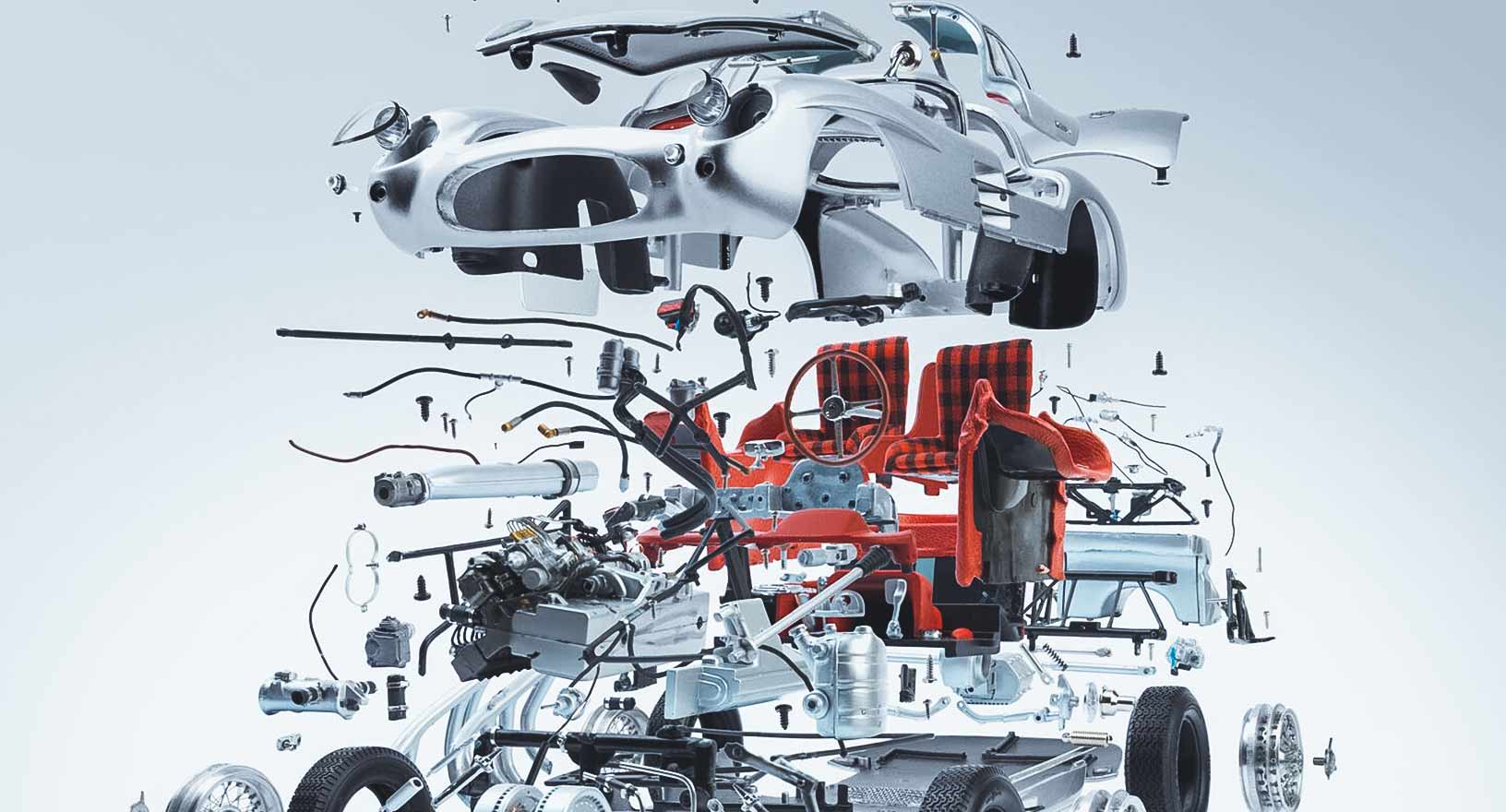

The mobility revolution sees automotive OEMs facing huge disruption. Not only are OEMs tasked with developing sustainable and commercially viable vehicles based on hybrid, electric, hydrogen or other emerging technologies, but they must also manage the impact of this shift on established industry operating models. Big tech companies and start-ups promising to deliver greater connectivity and autonomous vehicles also add to the competition.

Automotive OEMs are turning to digitalisation to provide the agility they need to compete in this dynamic market. Hexagon’s solutions are enabling digital twins for model-based engineering strategies to help OEMs remain relevant in a changing industry.

The automotive supply chain has delivered components at volume to OEMs using the "just-in-time" model for decades. However, the 2020 pandemic exposed limitations to the just-in-time approach. With today’s supply chain redundant for over 90% of electric vehicle components, the role of the traditional automotive supplier in future mobility is uncertain.

With the demands of new generation vehicles yet unclear, automotive suppliers must consider how best to position for success. Hexagon’s smart manufacturing solutions are helping automotive suppliers design agile manufacturing processes that adapt quickly to changing demands without impacting the ability to deliver at a competitive price.

As consumer desire shifts toward smart, connected and increasingly autonomous vehicles, big tech firms are becoming key mobility players. These proven technology pioneers with the ability to invest heavily for success draw inspiration from rapid innovation in the electronics and software fields to reduce development time and costs.

Hexagon is helping big tech firms in automotive use digital twins to develop and manufacture new vehicle concepts. Our sensor and software solutions enable cutting-edge autonomous vehicle testing, while our manufacturing technologies help unite digital-first innovation with manufacturing domain expertise in pursuit of future mobility solutions.

The automotive industry has traditionally relied on volume production, leveraging economies of scale in the supply chain to manage costs. This model made it difficult for start-ups to compete in the market. However, the shift to electric vehicles with fewer components is lowering the barrier to entry, and a new generation of automotive start-ups are injecting new ideas into mobility.

Like big tech companies, automotive start-ups embrace agile development and digital technologies. Greenfield factories give them the freedom to work without the constraints of existing production processes. Hexagon is working with automotive start-ups to reimagine mobility from concept to the road.