Complex and high-tech productivity gains with smart 3D measurement solutions

Faster and more accurate jig and mould production at Duc Trung Technology with the help of a Hexagon laser tracker 3D probing solution

Contact us

Smart laser tracker measurement solutions halve jig and mould measurement time

Established in 2014, Duc Trung Technology is a manufacturing company that specialises in making auxiliary products for high-tech industries in Vietnam. The business produces everything from individual production components such as jigs and moulds through to complete production lines.

The company’s range of services includes precision mechanical machining, with particular strength in manufacturing parts for heavy industry and that require complex machining and processing stages. The business is involved in providing welding jigs for automotive factories in Vietnam, and has also been a supplier of welding jigs for its international partners in Japan and Thailand.

The company’s range of services includes precision mechanical machining, with particular strength in manufacturing parts for heavy industry and that require complex machining and processing stages. The business is involved in providing welding jigs for automotive factories in Vietnam, and has also been a supplier of welding jigs for its international partners in Japan and Thailand.In addition, Duc Trung is also experienced in helping customers conceptualise, form and manufacture casting products and moulds with high precision, meeting global standards. The machining methods used at Duc Trung include mechanical milling, turning, copper wire cutting, CNC drilling, molybdenum wire cutting, grinding, seaming and polishing.

With an acute focus on product quality, and working in line with the company motto “Continuous improvement,” Duc Trung started to improve its operations after realising that their existing measurement system was not helping to maximise the operational efficiency of the business. They subsequently began to explore investing in a measurement system combining advanced hardware and software from Hexagon.

With an acute focus on product quality, and working in line with the company motto “Continuous improvement,” Duc Trung started to improve its operations after realising that their existing measurement system was not helping to maximise the operational efficiency of the business. They subsequently began to explore investing in a measurement system combining advanced hardware and software from Hexagon. The complete solution implemented by Duc Trung includes a Leica Absolute Tracker AT960-MR laser tracker and a Leica T-Probe handheld probing device, paired with Hexagon’s Inspire metrology software. The solution has helped Duc Trung to improve their production process by reducing measurement time by 50 percent.

Measurement time was halved – performance doubled

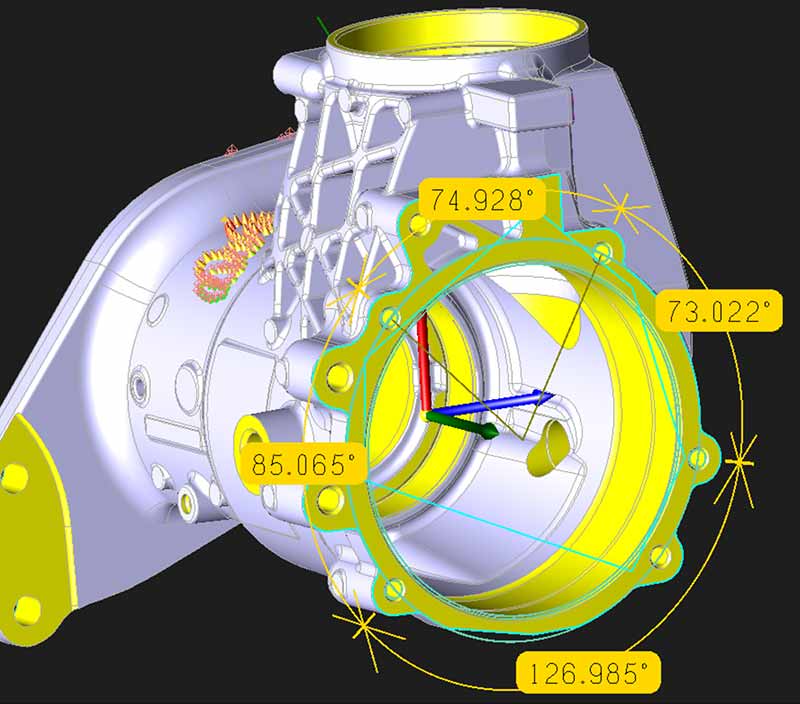

Before using Hexagon’s system, the production process with the old measurement equipment system at Duc Trung required a lot of time and effort to ensure quality and suffered from inefficiencies at several key process points. Changing to the AT960 combined with the T-Probe significantly improved productivity thanks to the extreme portability of the new 3D measurement system. The battery-powered mobile handheld probe uses infrared technology to achieve a wireless operating range of 10 metres, allowing for hidden point measurements within complex mechanical systems.

Changing to the AT960 combined with the T-Probe significantly improved productivity thanks to the extreme portability of the new 3D measurement system. The battery-powered mobile handheld probe uses infrared technology to achieve a wireless operating range of 10 metres, allowing for hidden point measurements within complex mechanical systems.The PowerLock target-locking feature that ensures an uninterrupted measurement process and the system’s extremely high and reliable accuracy throughout the measurement volume combine in a solution that has proven ideally suited for the large-sized, high-precision products Duc Trung Technology manufactures.

Notable applications for the new probing system include checking the standard latch positions on the jigs and aligning the jigsaw flexibly. In particular, the laser tracker’s repositioning feature expands the range of activities to help Duc Trung install and test jig welding lines along tens of metres of automotive systems.

“The laser tracker measurement system has helped us ensure product quality, shorten production time and save manufacturing costs.”

Mr. Nguyen Van Minh

General Manager

Duc Trung Technology

Prestigious and dedicated service – anytime and anywhere

The quality of Hexagon’s equipment had been verified and was trusted by one of Duc Trung’s more significant customers, and this reputation formed the basis of the business’ relationship with the Hexagon Vietnam team. However, the preeminent features of the AT960 laser tracker and the quality service provided by the Hexagon Vietnam team were the deciding factors for Duc Trung in choosing the proposed solution and implementing it within their factory.A lengthy consultative process to find solutions to help businesses improve operational efficiency is not the only objective of the Hexagon team. “Rather, Hexagon supports the service throughout, from the time of order until the completion of installation and beyond. The team have been conscientious in ensuring that the installation is running smoothly.” explains Mr. Nguyen Van Minh, General Manager of Duc Trung Technology.

“With a team of professional staff who always provide enthusiastic support, from the time of equipment purchase through the installation and into operation, we strongly believe in the quality of the products as well as the quality of the services delivered by Hexagon Vietnam.”

“Hexagon supports the service throughout, from the time of order until the completion of installation and beyond.”

Mr. Nguyen Van Minh

General Manager

Duc Trung Technology