Machine tool probing for landing gear struts and beams

Precision alignment of forged part and in-cycle checks to ensure the accurate machining of landing gear struts and beams

Contact us

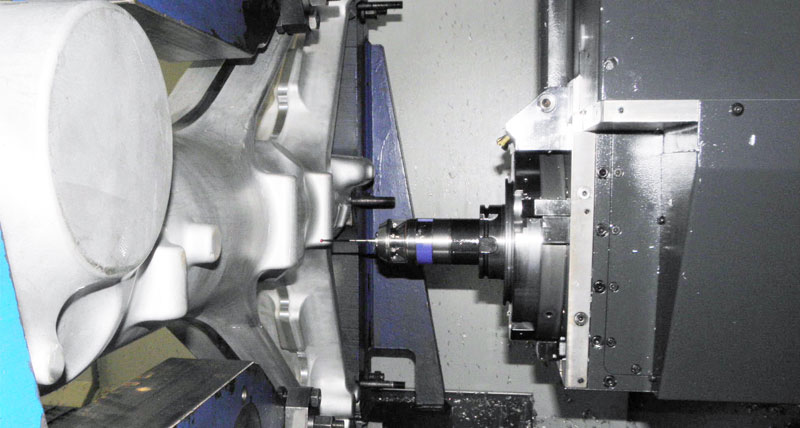

Landing gear struts and beams are made of large forged titanium or aluminium alloy parts, making them expensive parts to get wrong. Manually positioning blanks on machining centres introduces room for error. But with the right on-machine measurement tools, aircraft manufacturers can verify the precise positioning of a workpiece on a machine tool before the machining process starts and during the machining cycle.

Using machine tool probes to check the part position and adjust parameters while the part is on the machine tool can reduce material wastage significantly to increase overall productivity. Measurements can be made between each step of the machining program as required, bringing landing gear beam and strut manufacturers closer to producing parts right first time.

Hexagon provides machine-tool probes and specialised on-machine measurement software that enable aircraft landing gear manufacturers to automate the alignment of blanks for landing gear struts and beams. They also enable measurement and control of the tooling process while the workpiece is clamped to the machine to ensure minimal scrap.

Using machine tool probes to check the part position and adjust parameters while the part is on the machine tool can reduce material wastage significantly to increase overall productivity. Measurements can be made between each step of the machining program as required, bringing landing gear beam and strut manufacturers closer to producing parts right first time.

Hexagon provides machine-tool probes and specialised on-machine measurement software that enable aircraft landing gear manufacturers to automate the alignment of blanks for landing gear struts and beams. They also enable measurement and control of the tooling process while the workpiece is clamped to the machine to ensure minimal scrap.

Our solutions

Explore Hexagon solutions for on-machine probing of landing gear struts and beamsInfrared machine tool probes

The m&h IRP 25.50 touch probe allows machine tool operators to determination a workpiece’s zero point as well as its position, and measure its dimensions.

Software for machine tool probing

m&h 3D Form Inspect software features a patented calibration function that helps facilitate the precision machining of landing gear struts and beams.