WORKNC release history

Listed below are the current and previous releases of WORKNC

Contact us

-

WORKNC 2025.1

Discover the Latest Advancements in WORKNC 2025.1

The latest release of WORKNC introduces most required improvements in CAM programming, enhancing user experience, machining flexibility, and seamless integration with simulation tools.

Key Features & EnhancementsNext-Gen Toolpath Interface

With the redesigned toolpath interface, programming becomes more intuitive and efficient. You can now easily manage all major toolpaths with a modernized workflow. The ability to edit multiple toolpath parameters in a single step streamlines your process, saving you valuable time. By reducing complexity, WORKNC ensures a smoother programming experience, keeping you focused on achieving the best results.

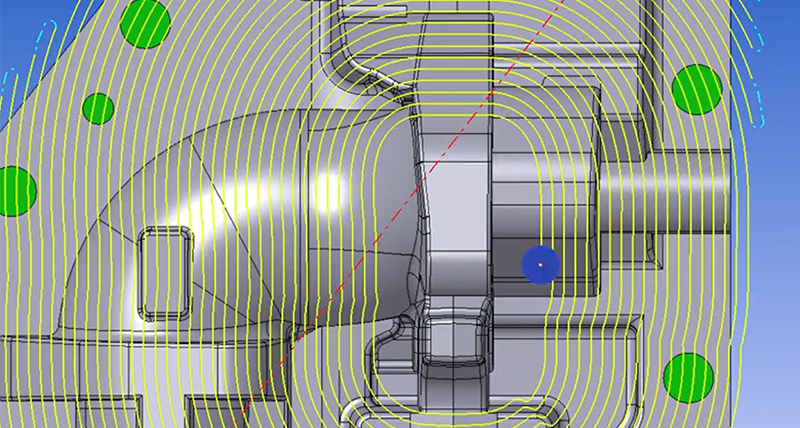

Concentric Pattern in Global Roughing

This new roughing pattern enhances cutting conditions while providing greater flexibility. By optimizing tool engagement and reducing retracts, you gain better tool life and smoother operations. Unlike traditional strategies, this method places less strain on your machine dynamics while still maintaining high-performance cutting. Now, you have more control to choose the best roughing approach based on your unique setup.

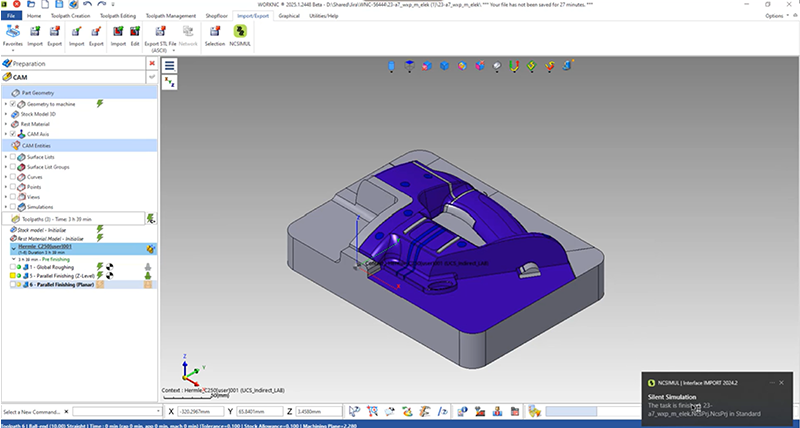

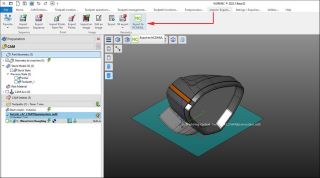

Seamless NCSIMUL Integration

Verifying your NC program has never been easier. With NCSIMUL running in the background, you can seamlessly check your toolpaths without disrupting your workflow. The traffic light system gives you immediate feedback—green means you’re good to go, red signals an issue that needs attention. This integration minimizes delays and allows you to proceed confidently, ensuring reliable machining operations.

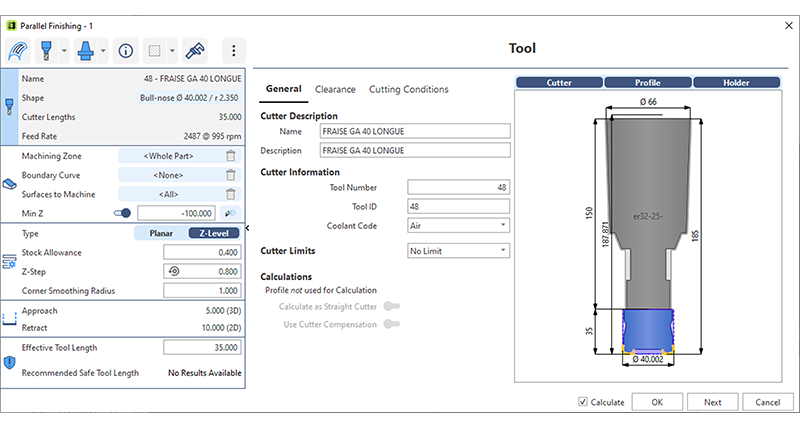

Parallel Finishing Enhancements

Achieve even smoother toolpaths while reducing machining time with optimized parallel finishing. Improved toolpath settings make configuration simpler, allowing you to focus on achieving a high-quality surface finish with minimal effort. Whether you're working with complex geometries or high-precision parts, this enhancement ensures the best possible results.

Advanced Calculation Model for All CAD Formats

With an improved watertight mesh model, your CAM calculations become more precise, leading to higher-quality surface finishes. Regardless of the CAD format you use, this enhancement ensures optimal machining accuracy. By refining the way surface data is processed, WORKNC 2025.1 helps you achieve superior results with fewer manual adjustments. Learn more about the features here.

Learn more about the features here. -

WORKNC 2024.3

The Next Generation CAM Solution for Mold and Die Manufacturing.

Precise Collision Avoidance in Global Roughing

Enhance accuracy by reassessing the correlation between the tool assembly and dynamic stock model. This leads to increased material removal, leaving a uniform stock after roughing, minimising the need for semi-finishing, and extending tool life with smoother tool paths.

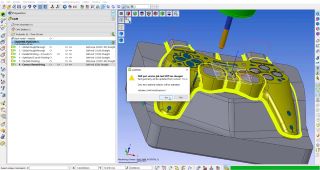

Next-Gen Toolpath Interface

Elevates the user experience by expanding the intuitive interface across all previous options, incorporating advanced strategies like our flagship Parallel Finishing. This enhancement simplifies the process with direct editing of key parameters, speeding up toolpath creation. It boosts productivity, engages users, and reduces programming time.

New Links for Parallel Finishing

The "New Links for Parallel Finishing" in WORKNC 2024.3 enhances the finishing strategy toolkit, optimising machining time and further consolidating our flagship strategy. By replacing three outdated strategies with cutting-edge technology, it ensures consistent lead-in and lead-out behaviour, while improving surface quality through advanced point distribution control.

New Toolpath Selection Dialog

WorkNC 2024.3 introduces the "New Toolpath Selection Dialog," delivering a modern, consistent interface that simplifies the selection of obsolete toolpaths.

Smooth Transition in Global Roughing

The "Smooth Transition in Global Roughing" feature ensures smoother transitions during machining, prolonging tool life and reducing overall machining time.

Global Finishing: Flat Surface Avoidance

The "Global Finishing: Flat Surface Avoidance" in WorkNC 2024.3 helps save valuable preparation time by replacing the outdated "Combined Z-Level + Optim Z Level" toolpath.

Rhino CAD Import

The "Rhino CAD Import" feature allows seamless data transfers with the direct import of native Rhino CAD files, enabling smoother geometry handling between applications.

-

WORKNC 2024.1

Improved user experience and enhanced productivity

WORKNC 2024.1 is enhanced with a series of new features designed to streamline your work and increase productivity.

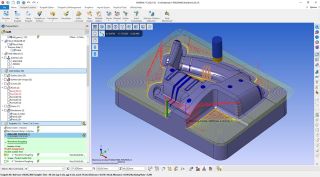

New Toolpath DialogThis upgraded toolpath interface brings main parameters right to your fingertips on the left-hand side. Additionally, it allows you to expand the dialog box to display all parameters, ensuring a comprehensive range of controls at a single glance.

- Enhance user engagement and productivity.

- Streamline user experience to reduce programming time.

- Efficiency through direct view and editing of the most important parameters.

- Combined with automation rules (tprules), programming a new toolpath is extremely quick.

Global Finishing

Integration of HxGN Global Finishing strategy provides top-notch toolpath generation times - another step in our continuous improvement journey of operational efficiency.

- Finish the whole part with a single toolpath.

- Enhance surface quality by optimizing toolpath ordering and controlling tool wear.

- Overcome the restriction of current toolpath “Combined Z-Level + Optim.”

Automated Global Roughing

The newly introduced automation feature drastically reduces manual input in computing multiple roughing toolpaths and only requires the selection of various tool assemblies. Preserve tool life by adapting cutting conditions.

- Let the system manager the collision avoidance.

- Avoid setting tricky options.

- Reduce manual input by 80% maximum.

Nexus Tool Library

The new connection from WORKNC to Nexus allows users to retrieve tool assembly from Nexus, ensuring tools are up-to-date and efficient.

- Avoid tool duplication in the library.

- Seamless workflow to exchange tool with other products (e.g. NCSIMUL)

- Easily share and keep tool UpToDate (cloud storage).

-

WORKNC 2023.1

A major release now available for download - visit the Customer Portal to update your software.

Benefit from significant new features, including:

Send to WORKNC | Syncronizing DESIGNER and WORKNC & send from VISI DESIGNER reads any CAD format and quickly prepares your geometry for manufacturing.

DESIGNER reads any CAD format and quickly prepares your geometry for manufacturing.Now the Workzone can be synchronized with the CAD file (vdf). Once a change is validated in DESIGNER (e.g. a new part revision or adding optional geometry), the user is automatically notified in WORKNC or while opening the workzone.

WORKNC detects the relevant changes in the CAD file and recalculates what is necessary. “Send from VISI” is equivalent to the DESIGNER command "send to WORKNC" but without synchronization.

User experience | New ribbon bar

The user experience has been modernized and enhanced by adding a new ribbon bar to WORKNC.

The user experience has been modernized and enhanced by adding a new ribbon bar to WORKNC.These new options will increase efficiency and productivity. It will enable a shorter learning curve for new users as it operates as all other Windows applications.

Users now have direct access immediately available to their favourite toolpaths. The Quick Access toolbar also provides access to background functions.

Global roughing | Dynamic maximum holder profile The maximum holder profile is the widest and most complex holder shape that can machine a particular area of the workpiece. At times programmers can find it difficult to predict the correct tool assembly for a given operation. This will reduce programming time and save money for standardising shopfloor holders.

The maximum holder profile is the widest and most complex holder shape that can machine a particular area of the workpiece. At times programmers can find it difficult to predict the correct tool assembly for a given operation. This will reduce programming time and save money for standardising shopfloor holders.Benefits include (a) fast and safe retrieve of the best holder suiting a given toolpath situation and reducing tool length, (b) flexibility to modify tool assembly on the fly to reflect shopfloor problematic, (c) reduce the variety of holders to buy, maintain and manage for each machine. Saving time in finding the best tool/holder combination is an innovation only available with WORKNC.

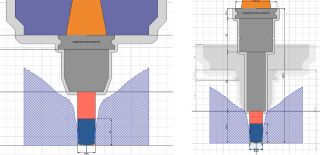

Global roughing | Tool life increase WORKNC users called for toolpath considerations that increase tool life and reduce machining time.

WORKNC users called for toolpath considerations that increase tool life and reduce machining time.WORKNC 2023.1 delivers with the introduction of a smoothing radius within the pocketing offsets with no extra programming.

This new capability is automatically calculated within the toolpath generation.

The addition of a radius has a significant positive effect on the cutting life of high-feed cutter inserts. It maintains a constant feed rate as much as possible.

This is implemented with a new lead-in material option with an "on-profile ramp". A 30% decrease in machining time was experienced in a recent milling test.

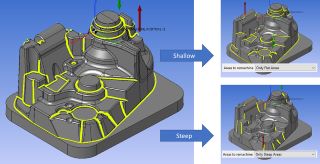

Countour remachining | Splitting steep and shallow areas These options allow the user to split the toolpath into passes into steep or shallow areas, allowing for different speeds and feeds to be used to improve machining time.

These options allow the user to split the toolpath into passes into steep or shallow areas, allowing for different speeds and feeds to be used to improve machining time.This gives programmers more flexibility to adapt tooling better and enables tools to work more efficiently.

It provides better tool durability and surface finishing without adding any programming complexity.

The result is to save money but reduce tool consumption while providing better quality finishing when remachining is required.

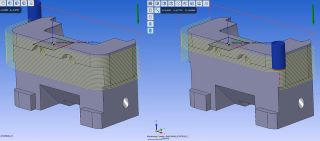

Parallel finishing | Vertical walls and other improvements Parallel Finishing (Z level) has significantly improved the management of vertical surfaces.

Parallel Finishing (Z level) has significantly improved the management of vertical surfaces.Some Z-Level passes are unnecessary in certain situations since they are not removing any material due to the undercut areas. With WORKNC 2023.1, a new option has been added to Enable/Disable these Floating passes.

It is now faster and easier to program Z-Level toolpaths as users can avoid editing and additional toolpath or surface creation.

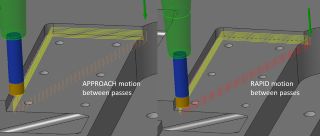

Curve profiling | Closing the gap In keeping with our goal of simplifying WORKNC, we are consolidating "Tangent to Curve" and "Curve Remachining" and replacing both with "Curve Profiling". Surface selection is now available in the same way as in "Tangent to Curve". Handling of 3D curves is available, previously limited to 2D curves.

In keeping with our goal of simplifying WORKNC, we are consolidating "Tangent to Curve" and "Curve Remachining" and replacing both with "Curve Profiling". Surface selection is now available in the same way as in "Tangent to Curve". Handling of 3D curves is available, previously limited to 2D curves.Better control of Lead-in and Lead-out with more efficient RAPID movements between passes where previously they were APPROACH movements. This modern algorithm speeds up calculation time and increases programming efficiency.

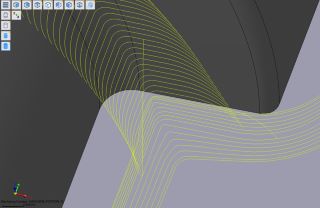

3-axis finishing | 3D smoothing radius WORKNC 2023.1 adds a new high-speed machining option to “generate rounded passes” to get higher-quality finishing. This option is available in 3D finishing,

WORKNC 2023.1 adds a new high-speed machining option to “generate rounded passes” to get higher-quality finishing. This option is available in 3D finishing,3D drive curve finishing, Optimized Z-level finishing (spiral cycle only), Z level Remachining (contour optimization), and Contour remachining.

The 3D smoothing radius option leads to less hand polishing and results in considerable savings in labour time and speed of final part delivery.

NCSIMUL standard | Single interface to export a CAM project

NCSIMUL helps WORKNC customers to validate NC toolpaths on the shop floor.

NCSIMUL helps WORKNC customers to validate NC toolpaths on the shop floor.NCSIMUL gives confidence to the machine operator by checking programs to avoid collisions and speed up machine cycle times.