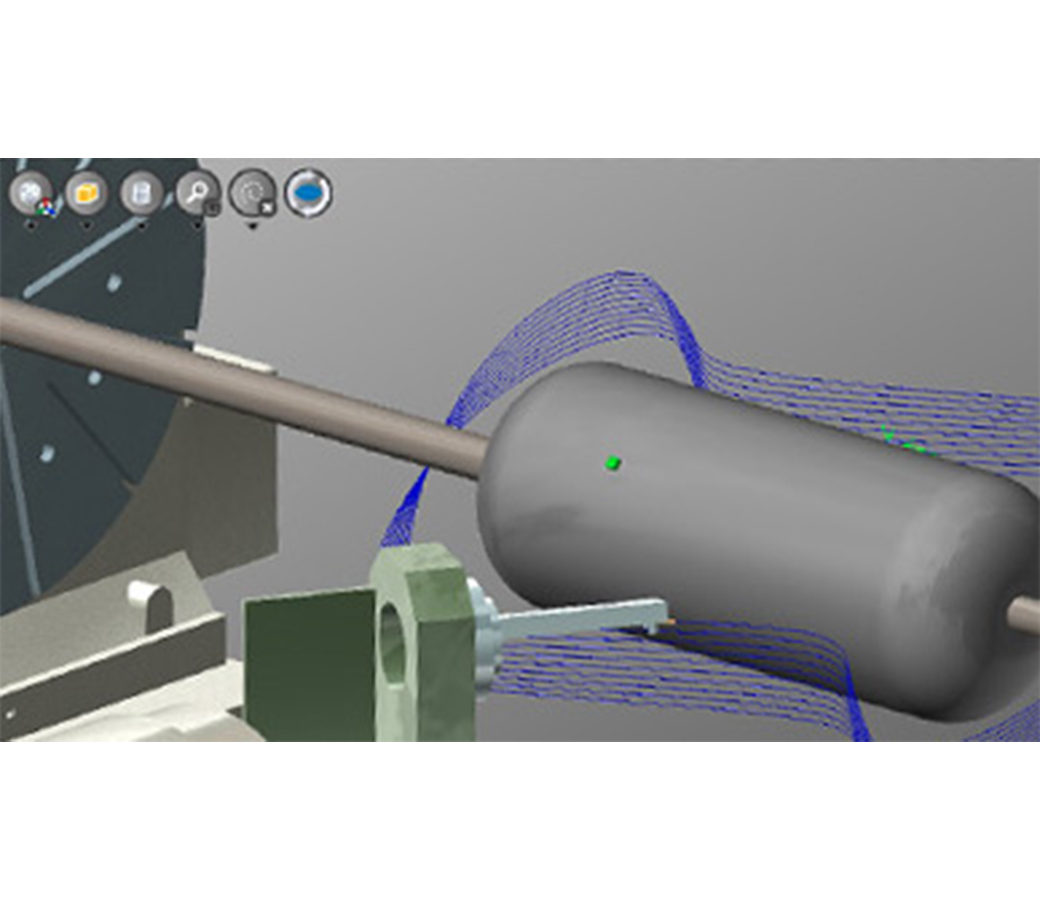

NCSIMUL Machine Composites allows realistically and efficiently material lay-up simulation, according to different methods: fiber positioning (filaments or ribbons) or filament winding, with automatic collection of machining simulation data (e.g. 3D, cycle time, and cutting conditions, laid-up fiber length...).

- Taking into account the initial media, the already laid material and the roller position

- Precise & independent positioning of each fiber in ribbon

- Cutting control for each fiber

- Powerful viewing of the full model of the final part (with selective, layer-by-layer display)

- Measurement of laid-up plies: ply thickness, angle and distance between ribbons

NC program analysis

- Display the ply path as soon as the NC program is loaded

- Decode the G-code; vendor macros, including variables and structured programming; e.g. Siemens840D, Heidenhain, Fanuc

- Automatically detect program errors : ISO syntax, out-of-range motion

- Take advantage of the link between 3D window, program and information window

- Use the code editor for direct correction (universal controller)

- Quickly display real NC parameters : variables, machine status, etc.

Material lay-up simulation

- Precisely compute lay-up in real time

- Detect possible collisions and material lay-up

- Move around, rotate and zoom smoothly during the simulation

- Unlimited file size

- List lay-up and collision issues: unstretched fibers, steering and no contact between rough stock and material

- Use simulation to correct the program completely

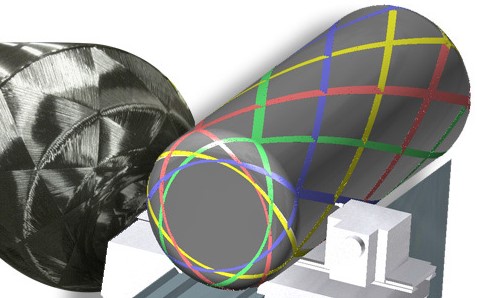

Results analysis

- Use dedicated tools to check and monitor the lay-up process: laid up fiber length, layer thickness measurement, ribbon intersection angles, distance between fibers, etc.

- Create dynamic 3D sections of the results

- Export the simulation results (3D envelope, path, layer,...) to the design office

- Enjoy the advantages of ergonomics, user experience and the interface between NCSIMUL Machine and your CAM implementation

- Simulate the G-code for your material lay-up realistically and powerfully with fiber placement and filament winding

- Detect collisions and alerts: unstretched fibers, steering, no-contact conditions between rough stock and material

- Display and compare the actual laid-up ply path with the programmed path

- Take advantage of the interactive relationship between the 3D window, the program and the information window

- Universal Machine Technology supports an unlimited number of axes (robots or complex NC machines)

- Interfaces with most commercial CAD/CAM softwares, notably CATIA, NX, Pro/ENGINEER, MasterCAM, Edgecam, TopSolid CAM