Hexagon and Sciaky partner to unlock the full potential of Electron Beam Additive Manufacturing (EBAM®) for high-value parts

15 November 2021

Hexagon’s Manufacturing Intelligence division has entered a partnership with Sciaky, Inc, a leading supplier of industrial metal 3D printing solutions and subsidiary of Phillips Service Industries, Inc. (PSI), to enhance its innovative EBAM® technology with predictive analysis tools.

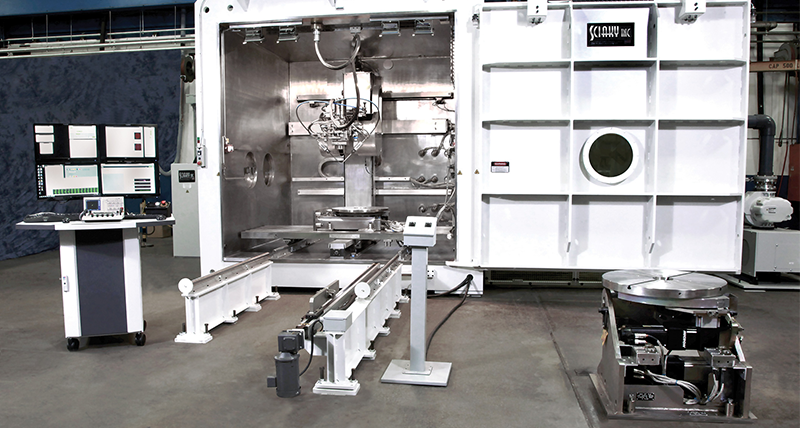

Sciaky’s turnkey EBAM metal 3D printers use high-value materials, such as titanium, tantalum, and nickel-based alloys, to produce parts and structures up to 20 feet in length. This award-winning process has produced large-scale parts significantly faster, cheaper and with less waste than traditional manufacturing methods for some of the largest aerospace companies in the world.

Printing large parts composed of high-value metals can be tricky because material behaviours are tougher to predict for large geometries. To address this matter, Sciaky’s unique Interlayer Real-time Imaging and Sensing System (IRISS®) enables closed-loop control of the EBAM 3D printing process to eliminate variations and improve its quality and production throughput by sensing and digitally self-adjusting metal deposition in real-time, with precision and repeatability.

To further support EBAM’s closed loop control, Hexagon’s Simufact solution has been validated to accurately simulate the thermal-mechanical behaviour of the DED process, enabling users to analyse thermal history, stresses, strains, and distortions throughout the process and optimise build setup and process parameters virtually before deposition. As a result, the software reads EBAM’s printer trajectories and process parameters directly, reducing the effort required to produce the simulation model. The entire process is streamlined because the G-code is directly compensated within the software.

“Sciaky’s customers demand high quality, high-performance parts,” said Scott Phillips, President of Sciaky, Inc. “Hexagon’s Simufact solution helps increase confidence for our customers to ensure the best quality outcome.”

“Our goal is to deliver process simulation solutions that enable manufacturers to perform predictive analyses for parts faster than the part can be physically built and measured,” said Jeff Robertson, business development – virtual manufacturing and costing solutions, Hexagon, “Not long ago, it took months to complete high-quality simulations for these types of additive processes, but through our collaboration we now have the ability to make the same accurate predictions in days or hours, so the technology can facilitate the efficient use of Sciaky’s powerful additive capabilities for parts of any size or complexity.”

To learn more about Sciaky, visit https://www.sciaky.com

To learn more about DED simulation, please visit https://www.simufact.com

About Sciaky, Inc.

Sciaky, Inc., a subsidiary of Phillips Service Industries, is a world leader in metal 3D printing technology and EB (electron beam) welding solutions. Our exclusive Electron Beam Additive Manufacturing (EBAM®) process is the fastest, most cost-effective 3D printing process in the market for large-scale metal parts, allowing manufacturers to save significant time and money over traditional manufacturing and rapid prototyping processes. Sciaky’s industry-leading EB welding systems and job shop services meet rigid military specifications to manufacture items such as airframes, landing gear, jet engines, guided missiles and vehicle parts. For more information, visit www.sciaky.com

About Hexagon

Hexagon is a global leader in sensor, software and autonomous solutions. We are putting data to work to boost efficiency, productivity, and quality across industrial, manufacturing, infrastructure, safety, and mobility applications.

Our technologies are shaping urban and production ecosystems to become increasingly connected and autonomous – ensuring a scalable, sustainable future.

Hexagon’s Manufacturing Intelligence division provides solutions that utilise data from design and engineering, production and metrology to make manufacturing smarter. For more information, visit hexagonmi.com.

Hexagon (Nasdaq Stockholm: HEXA B) has approximately 20,000 employees in 50 countries and net sales of approximately 3.8bn EUR. Learn more at hexagon.com and follow us @HexagonAB.

Contact:

Robin Wolstenholme (UK based)

Global Media Relations and Analyst Relations Manager

Hexagon’s Manufacturing Intelligence Division

Phone: +44(0)207 0686562

e-mail: robin.wolstenholme@hexagon.com

Stacey Wiebe (US based)

Global Media Relations Officer

Hexagon’s Manufacturing Intelligence Division

Mobile: +1 209 479 9455

e-mail: stacey.wiebe@hexagon.com

media.mi@hexagon.com