Visualise this! Design and inspection go hand-in-hand

Jewelers Machinists Co. Inc. - USA

Contact us

Pawloski has invented a groundbreaking, energy-efficient drive that is sure to set the industry on its ear. While cleaning out the bearings of a drive system, a new design appeared in his mind’s eye. The concept appeared to him again in the middle of the night. Not only was it a premonition, the mental picture became his personal challenge to take an idea and make it better, much better.

John’s grandfather founded Jewelers Machinists in 1947 in Brooklyn, NY to produce parts for jewellery-making machines for New York City area customers. The business was run by his father until an early illness forced John, age 20, to leave college and join his brother to take charge of the family’s manufacturing company. During his father’s tenure, the company ventured into lathe and milling work, then moved strictly into thread grinding. John and his brother modernised the facility, bought CNC thread grinders, and tripled the size of the company. Today, they serve clients in the aerospace industry and conduct work in the commercial business sector for actuator systems, worms and armature shafts.

Driving a vision toward reality

Convinced his concept would work, Pawloski explored the design on paper, created a prototype and contacted a patent attorney. The new drive would consist of two balls, a cup and a shaft. Once the system is angled, it engages and the normal force builds up on the balls to transmit torque. For this very simple, yet sophisticated system, his design intent was to have all components cost-effectively manufactured.

In the prototyping phase, John faced many challenges such as building a custom grinding machine and producing all components necessary for the drive. After the initial proof of concept stage, Pawloski had to learn new tricks of the trade. Self-taught on a CAD system, he built accurate models of each part in the assembly, generated blueprints, then moved into a more advanced level of prototyping.

The exhaustive product development process for the new drive system went through many iterations to perfect the design. During the early stages of the project, Pawloski had to devise a new adaptor for their CNC thread grinding machines, housing and spindles, so they could grindparts in-house. This strategic move enabled the company to keep the prototyping costs down, which can run into tens of thousands of dollars.

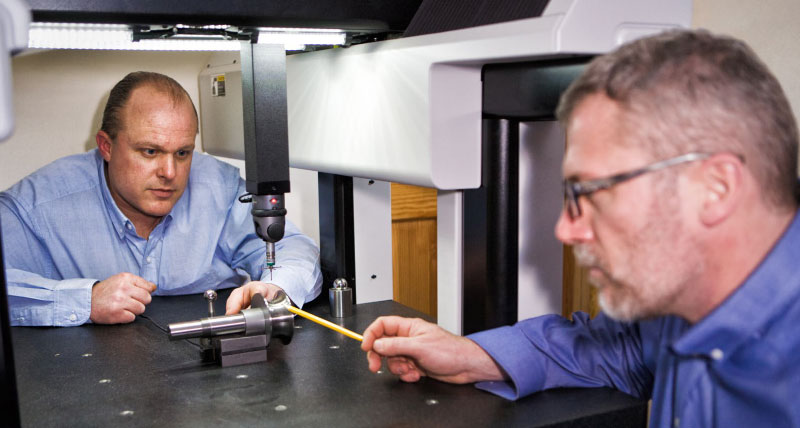

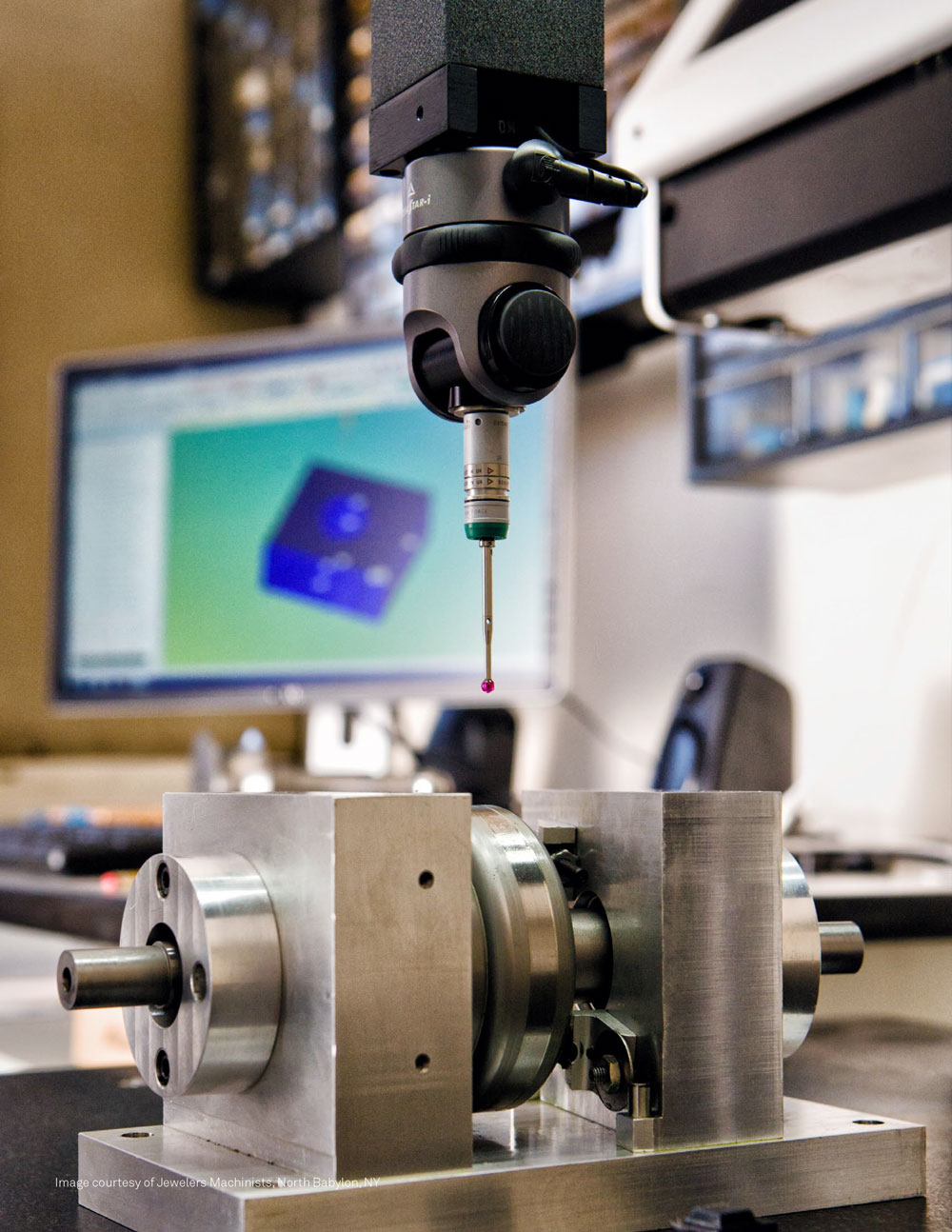

There were three stages for the prototype; each iteration bumping up the size of the unit. Then, the project hit a roadblock. Progressing to a unit larger in size, it was evident they could not verify radii and other critical features. John could no longer rely on the usual tricks of the trade, such as wire measuring to provide accurate, dimensional control of the evolving design. It was time to invest in a high precision coordinate measurement machine (CMM).

Measurement: the reality check for manufacturing

Once Pawloski integrated a new CMM into his process, product development amped up significantly. He used the shop floor 4.5.4 SF to routinely check critical radii and 30 vital points, then continue to improve the design with much greater confidence.

“From the start, Hexagon worked very closely with me to ensure the 4.5.4 SF was the right solution. They took my parts back to their lab, measured and delivered the results. Finally, I had a precision tool to measure large internal and external radii on the shafts of the design,” stated Pawloski. “I could check the accuracy of the diamond roll machine, and monitor their combined error. I would perform periodic spot checks on several points on the profile, and take additional points to verify the diamonds were not wearing on the grinding machine. The bearings in this design need to roll on a nice curve, not a flat area.”

The entire assembly has associated CAD models, which are downloaded directly into PC-DMIS, Hexagon Manufacturing Intelligence’s inspection software. Pawloski picked up the software’s functionality quickly. An important step in the process was checking the assembled section of the design radii, points and datum points that reference those radii all measurements critical to the construction of the drive.

“The CMM fit right through the shop door, and it needs no air. This plug-and-play machine was needed in our facility,” recalls Pawloski. “The PC-DMIS software is very easy to use; it’s just common sense.” The 4.5.4 SF, with a compact footprint and roll-around stand, is a new generation CMM designed specifically for harsh shop-floor conditions.

Like Pawloski’s invention, the rugged CMM was inspired by taking a good design and making it exponentially better. The 4.5.4 SF ushered in new innovations like advanced thermal compensation, covered ways,built-in vibration resistance and optional contact analog scanning. The CMM also uses standard 110/220 volt outlets. Because the CMM was designed specifically to fit through a standard door, it can be used for precise dimensional inspection anywhere in the shop.

Jumping the hurdles of new product development

Once the CMM became an integral part of product development, the project progressed into the “scientific phase.” Pawloski reached out to two industry experts for advice and expertise: Dr. Christopher DellaCorte,one of the head tribologists studying the application of friction, lubrication and wear for NASA, and Dr. Lawrence Weber of the NYSTAR Centre for Advanced Technology in Diagnostic Tools and Sensor Systems at Stony Brook University.

“When you test a gear box, or any type of mechanical device, there are a few ways to do it,” stated Pawloski. “A theoretical model can be built, but I wanted to dynamically test the design in the real world. You have the math behind the design, but then there is also the reality of the system in use. I bought rotating torque sensors, which could test torque in and torque out, and get a reliable read on efficiency. Those numbers don’t lie.”

Not satisfied with the status quo, John delved further into the inner workings of his drive. There was a lot of practical knowledge to be gained in terms of the way mechanical devices function, especially in the areas of friction, lubrication and interacting surfaces in motion. Pushing the envelope hard at this stage, he focused on testing all facets of the system to break barriers in energy efficiency. At one point, he tested 10 different types of motor oil to evaluate any change in temperature created by fluid friction. Building his knowledge base about energy efficient design, Pawloski applied for another patent, which further increased the simplicity of the system.

The end game

Named by his wife and daughters, the Marmalade Drive has far reaching implementation opportunities. Pawloski decided to start with air handling systems for buildings utilised by pizzerias and government agencies. The drive’s energy efficiency consistently lies within a tested 97-98% range, which has been proven through mathematics and dynamic testing. An average pizzeria would sav eclose to $450 –$500 a month in electrical costs. Currently, Jewelers Machinists is working with a large, local mom and pop pizzeria with nearly 30 blowers. It is estimated they will save well over $20,000 a year. There are other planned installations for buildings with 500 to 1,000 blowers, resulting in tremendous savings.

Choosing the first market to serve was a hard decision for the inventor. The units have multiple uses, for example, one drive can be used for blowers and conveying systems. Products that require speed reducers or accelerators are especially appropriate, such as high-accuracy telescopes, windmills and more. Jewelers Machinists has chosen industry partners to market, sell and install their new product line.

For Pawloski, the development of the new drive system was not monetarily driven; it was a challenge...a process of visualisation, pleasure and problem-solving. “Moving forward, as we envision new concepts for our units, we are free to refine our ideas with confidence. Going to a CMM offers a beautiful comfort. When I need to make design changes or try ideas for the different units, I can accurately check the results. In a way, the prototyping phase of this system was a tolerance study. We have built a tolerance for all those parts, which was the last part of the puzzle for this product. There are units ready for market, and I am excited for the future.”