Using Nexus for design reviews in machine shops

by Stephen Graham, EVP & General Manager Nexus,Hexagon’s Manufacturing Intelligence division

Engineering Reality 2023 volume 2 edition

Empowering makers for an autonomous sustainable future

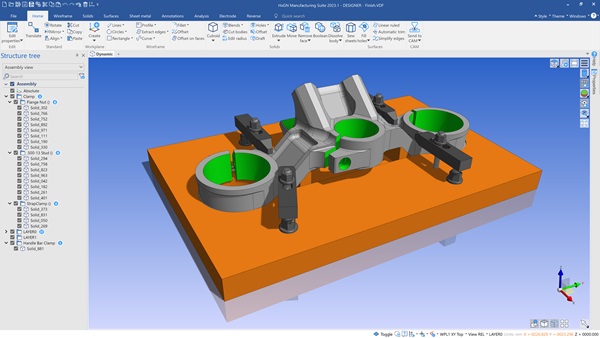

Figure 1. Prepare the part for manufacture using Hexagon’s CAD for CAM software, DESIGNER.

CAD drawings often express customer requirements, usually 2D drawings in PDF files or printouts. Rarer but more helpful, customer requests arrive as full 3D CAD files. Utilising these files enables a better understanding of the customer’s needs and facilitates identifying potential issues.

A typical machine shop business starts discussions with the customer to fully understand the requirements, explore any manufacturability challenges, and ultimately set a price for the job.

Customers already have access to Hexagon’s DESIGNER, a robust CAD solution targeted specifically for machine shop needs. Users can import CAD files from different formats or create a 3D CAD model from 2D drawings. These options allow the CAM engineers to explore the model in more detail to understand requirements better. Often, the CAD model must be cleaned up before it’s ready for machining – gaps and other imperfections must be resolved before programming the machine. As the engineers explore the model, they may find features challenging to machine. In doing so, they may discover that tolerances specified by the designer are unrealistic or expensive.

Two-way communication with the customer is essential to finding the optimum compromises for manufacturability and cost whilst ensuring the part delivered still fulfils the customer’s requirements.

The customer must also agree upon any tweaks to the CAD model in case they impact the final part’s performance. Discussions must occur rapidly and depend on strong relationships between production engineers working at the machine shop and customers ordering the parts. That lack of documentation can lead to problems if something goes wrong.

Quoting is another significant challenge for machine shops. There is, of course, pressure to quote a competitive price, but rarely time to complete the end-to-end engineering work needed to understand the cost of producing a part. Machine shops, therefore, lean heavily on their experience to estimate prices and typically believe they will “win some” and “lose some.” Customers often prefer the most competitive price, so machine shops may more often “lose” than “win.”

Figure 2. Review designs with clients in the Nexus 3D Whiteboard collaborative web application.

How Nexus can help with these challenges

Nexus enables real-time collaboration across disciplines and between customers and suppliers throughout the product life cycle and the value chain. Specifically, the “Design Reviews for Machine Shops” Solution helps machine shops in the critical negotiation and quoting phases.

DESIGNER, powered by Nexus, connects and shares data in real-time. Once a CAD model is available in DESIGNER, the machine shop can invite their customer to join a Nexus 3D Whiteboard session. During these sessions, the CAD model comes to life in an interactive environment on-screen. The machine shop’s production engineer and the customer’s designer can interact with the CAD model in real-time, zooming in to discuss areas of concern and highlighting features that need attention.

As the discussion progresses, the production engineer can change the CAD model in DESIGNER as needed, reflecting all changes in real-time on the 3D whiteboard. Anyone participating in the session can add sketching and annotations to the model on the whiteboard in 3D. When the session concludes, participants can save a record of the discussion.

The collaborative and informal nature of the 3D whiteboard nurtures a positive relationship with the customer, while the ability to save the outcome helps document whatever was agreed upon. If issues arise, the engineers can return to the whiteboard anytime to discuss.

After finalising the CAD model in a collaborative 3D whiteboard session, users can import it directly from DESIGNER into whichever CAM software the machine shop

prefers to programme the CNC machines. They can also import that same CAD model into the preferred metrology software to prepare any dimensional quality inspection that may be needed, depending on the specification of the part and the required tolerances.

By completing this engineering work, the machine shop can accurately estimate the cost of producing a part. This cost estimate is shared with the customer to ensure the job is profitable.

It can still be burdensome to complete the engineering work before making a quotation, especially if it is uncertain that the machine shop will be awarded the contract for the part in question. This can lead to a lot of engineering effort wasted on jobs lost to competitors. For this reason, the “Design Reviews for Machine Shops” solution will continue to evolve in the future, simplifying and automating the downstream engineering processes to make it easier to generate quotations based on accurate estimates of machining and measurement time and equipment.

The Design Reviews for Machine Shops Solution will be available to machine shops subscribing to Nexus from the end of August 2023.

Visit nexus.hexagon.com for more details.