Trifibre’s “Jigsaw” nests in ALPHACAM aid bottom line

Trifibre - U.K.

Contact us

It was an open and shut case when Leicester-based Trifibre were looking for CAD/CAM software to drive their new CNC router. They chose ALPHACAM. And now, around five years later, it programs their Biesse Rover, a Morbidelli, and their original small Pacer.

Established in 1981, Trifibre Ltd has grown into the UK’s leading case producer, providing innovative casing design and manufacturing solutions to a wide range of industry sectors including aerospace, surgical and medical, motorsport and automotive, and clothing.

Sales Manager Trishanth Parari says they specialise in working with major blue chip organisations, manufacturing flight cases that meet military specifications, bespoke polyprop cases, complex bespoke metal containers, made to measure metal fabrications, wooden packing crates, and custom made wooden and plastic presentation cases.

polyprop cases, complex bespoke metal containers, made to measure metal fabrications, wooden packing crates, and custom made wooden and plastic presentation cases.

Trifibre invested in ALPHACAM when they purchased the Morbidelli to supplement the Pacer. “Previously, everything was routed manually. We simply added tool paths to the DXF files,” he says. “However, as the company grew we needed to reduce our labour time in producing drawings and preparing the machines.

“The shop floor workers were physically routing the panels every day, and it was becoming increasingly inefficient to machine the foam inserts on the single head Pacer, so we brought in the Morbidelli which was a pod and rail system, and we converted half the bed into a flat bed. As it’s a twin-head machine we’re able to run it in tandem, programmed with ALPHACAM.”

And Project Manager Martin Clarke says the next natural step was to further expand their CNC suite. “Moving from the single head Pacer to the twin head Morbidelli improved efficiency in terms of speed and accuracy in cutting the inserts, and they were passing through the factory faster than the panels. So we decided to purchase the Biesse Rover for routing the panels.”

ALPHACAM is involved in almost everything he does: “Everything that’s machined, every hole, every pocket – the more time we invest upfront turns into savings of minutes and hours. What one person does with ALPHACAM in the office saves time for 20 people on the shop floor.”

He says once a prototype is approved, programming all three machines with ALPHACAM enables them to produce the same product quickly and efficiently every time. They use specific software for designing their flight cases, and the DXF file containing all the panel sizes, handle cut-outs and catch holes, is imported into Alphacam for the toolpaths to be added.

“This goes to the shop floor where the CNC machine operators create the nests getting the most efficient yield from every sheet…even where we’re producing one-offs. For example, we can create a jigsaw of 20 one-off cases on the same nest. A one-off flight case may only need a quarter or half sheet of Hexaboard plywood, but prior to using ALPHACAM we might have to use a full sheet.

“Waste is expensive, but ALPHACAM creates what is essentially a jigsaw puzzle for routing, compared to the straight cut saw and beam saw where you’d have to go right through a panel. On our widely used materials, such as Hexaboard, the yield is well up around 90 per cent, so this represents considerable savings. ALPHACAM improves yield, and yield becomes profit margin, so ALPHACAM is directly contributing to our bottom line and profitability.”

It also saves considerable time, which, again, improves efficiency and profitability. “It varies from job to job, but the bare minimum is hours down to minutes. And when we’re machining high production runs of the same case with a number of intricate routes, it can save us days.”

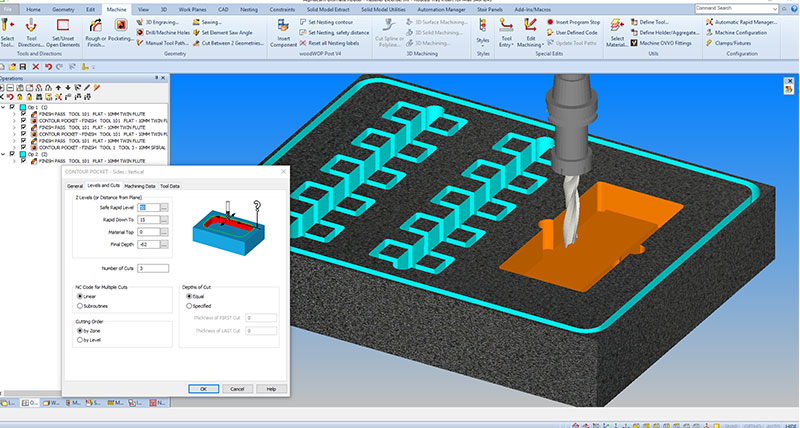

Trishanth Parari says another aspect of ALPHACAM which plays a vital part in their production is simulation. “We’re able to see what the end product is going to look like before we start to cut the material. It’s also important to ensure that there aren’t going to be any collisions during the manufacturing process.”

And he says having one software package to drive the routers from all three machine tool manufacturers makes their working lives considerably easier. “With ALPHACAM we have post processors set up for each CNC machine, so we can simply send the program to the shop floor knowing it will be absolutely right.”

In conclusion, he says ALPHACAM means they can offer a maximum turnaround time of 14 working days on all orders – whether it’s for one case, or 100.

Established in 1981, Trifibre Ltd has grown into the UK’s leading case producer, providing innovative casing design and manufacturing solutions to a wide range of industry sectors including aerospace, surgical and medical, motorsport and automotive, and clothing.

Sales Manager Trishanth Parari says they specialise in working with major blue chip organisations, manufacturing flight cases that meet military specifications, bespoke

polyprop cases, complex bespoke metal containers, made to measure metal fabrications, wooden packing crates, and custom made wooden and plastic presentation cases.

polyprop cases, complex bespoke metal containers, made to measure metal fabrications, wooden packing crates, and custom made wooden and plastic presentation cases.Trifibre invested in ALPHACAM when they purchased the Morbidelli to supplement the Pacer. “Previously, everything was routed manually. We simply added tool paths to the DXF files,” he says. “However, as the company grew we needed to reduce our labour time in producing drawings and preparing the machines.

“The shop floor workers were physically routing the panels every day, and it was becoming increasingly inefficient to machine the foam inserts on the single head Pacer, so we brought in the Morbidelli which was a pod and rail system, and we converted half the bed into a flat bed. As it’s a twin-head machine we’re able to run it in tandem, programmed with ALPHACAM.”

And Project Manager Martin Clarke says the next natural step was to further expand their CNC suite. “Moving from the single head Pacer to the twin head Morbidelli improved efficiency in terms of speed and accuracy in cutting the inserts, and they were passing through the factory faster than the panels. So we decided to purchase the Biesse Rover for routing the panels.”

ALPHACAM is involved in almost everything he does: “Everything that’s machined, every hole, every pocket – the more time we invest upfront turns into savings of minutes and hours. What one person does with ALPHACAM in the office saves time for 20 people on the shop floor.”

He says once a prototype is approved, programming all three machines with ALPHACAM enables them to produce the same product quickly and efficiently every time. They use specific software for designing their flight cases, and the DXF file containing all the panel sizes, handle cut-outs and catch holes, is imported into Alphacam for the toolpaths to be added.

“This goes to the shop floor where the CNC machine operators create the nests getting the most efficient yield from every sheet…even where we’re producing one-offs. For example, we can create a jigsaw of 20 one-off cases on the same nest. A one-off flight case may only need a quarter or half sheet of Hexaboard plywood, but prior to using ALPHACAM we might have to use a full sheet.

“Waste is expensive, but ALPHACAM creates what is essentially a jigsaw puzzle for routing, compared to the straight cut saw and beam saw where you’d have to go right through a panel. On our widely used materials, such as Hexaboard, the yield is well up around 90 per cent, so this represents considerable savings. ALPHACAM improves yield, and yield becomes profit margin, so ALPHACAM is directly contributing to our bottom line and profitability.”

It also saves considerable time, which, again, improves efficiency and profitability. “It varies from job to job, but the bare minimum is hours down to minutes. And when we’re machining high production runs of the same case with a number of intricate routes, it can save us days.”

Trishanth Parari says another aspect of ALPHACAM which plays a vital part in their production is simulation. “We’re able to see what the end product is going to look like before we start to cut the material. It’s also important to ensure that there aren’t going to be any collisions during the manufacturing process.”

And he says having one software package to drive the routers from all three machine tool manufacturers makes their working lives considerably easier. “With ALPHACAM we have post processors set up for each CNC machine, so we can simply send the program to the shop floor knowing it will be absolutely right.”

In conclusion, he says ALPHACAM means they can offer a maximum turnaround time of 14 working days on all orders – whether it’s for one case, or 100.