Radan nests and bending “vital” for KMF

KMF - Staffordshire

Contact us

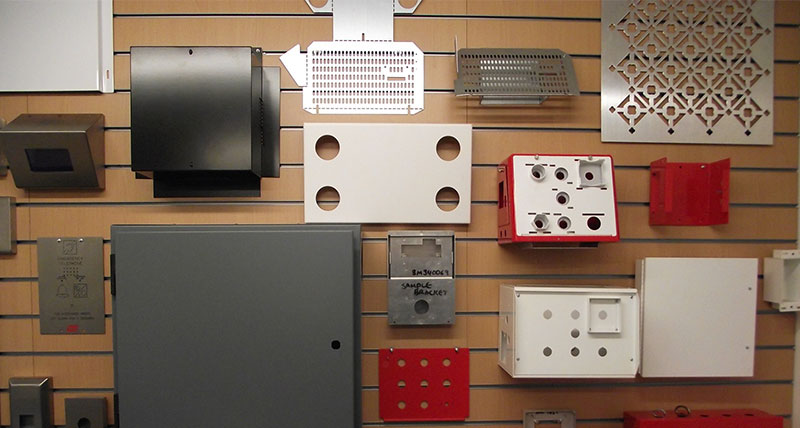

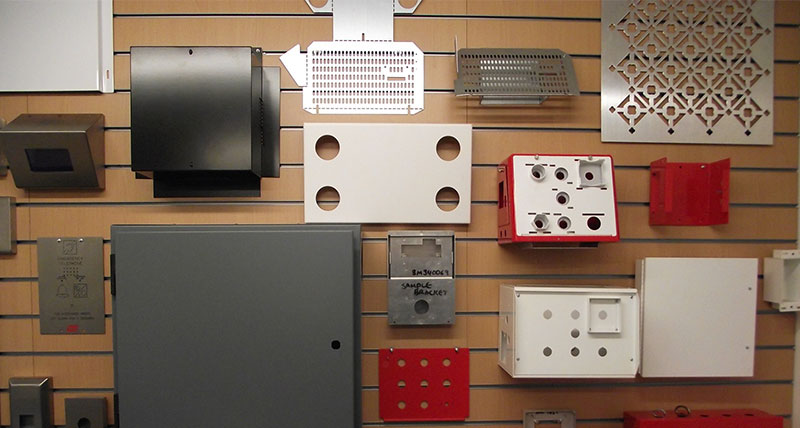

Manufacturing components for such diverse products as premium class aircraft seating, coffee vending machines and electrical distribution boards, the UK’s largest sheetmetal subcontractor says specialist CAM software is vital to nest a range of parts for several customers on the same sheet.

Operating from a 120,000 square foot facility in Staffordshire, KMF Precision Sheetmetal Ltd ships around one million piece parts every month. Programming Manager Stephen Gardener says the Radnest function within their Radan sheetmetal CAD/CAM system from Vero Software saves time and reduces scrap.

“It plays a large part in our day to day business, and we use it in two different ways. Firstly, it consolidates large assemblies where we want to produce an exact amount of parts to match the Bill of Materials. A number of our assembly jobs consist of 100 or more parts, and the Project Nesting function means we can nest different materials and thicknesses on different sized sheets. These would typically be saved as a project, with all nests saved under one job number.

“And secondly, it gives us the ability to nest small batch quantities. If a customer wants five off, we can nest them on sheets with components for other customers. But if we had to run a full sheet program for just five parts it could leave us with about 20 per cent waste.

“And secondly, it gives us the ability to nest small batch quantities. If a customer wants five off, we can nest them on sheets with components for other customers. But if we had to run a full sheet program for just five parts it could leave us with about 20 per cent waste.

“As our batch sizes can vary from one off to thousands off, we have a full time nesting office analysing all jobs to see if the quantity justifies running its own nest program. If it doesn’t, the parts will be separated and nested with parts for other customers. This way we can maximise sheet utilisation for any batch quantity.”

KMF have used Radan for many years to drive their range of Trumpf punch presses, punch/laser combination machine tools, and lasers. But a manual press brake operation for the bending process caused a considerable bottleneck with a typical set-up taking around 45 minutes. He says investing in Radan’s specialist Radbend module for programming press brakes has slashed set-up time by at least half. It also means they can frequently set up a job using just one part, saving save four or five parts on one set-up.

“And Radbend minimises waste by simulating the full bending sequence before starting to fold metal. Operators simply call up the program and view it in 3D on their machine console.”

Overall, KMF run Radraft, Radan 3D, Radprofile and Radpunch on a number of Trumpf machine tools, all fed with Stopa tower systems, and two of them using a ShearMaster to cut sheet skeletons. The CNC shop comprises three fully automated punches, two punch/laser combinations, and two lasers. And Radbend programs nine Trumpf press brakes, including a lifting arm on a 5130, which allows one operator to bend large panel work.

Their process with Radan begins by importing the 3D data, then determining the material properties and producing a flat development with bend allowance, which is sent straight to the profiling or tooling stage. “At this point we can also use Radraft to alter any details or features before tooling, and then add either laser profile or punch tools. We’d use auto tooling in both cases, and tweak manually if necessary, to optimise the tooling. Nesting ensures best sheet utilisation, and Radbend produces programs for the press brakes, either straight from the model or by Radraft’s ‘fold from flat’ feature.

“All this combines to give us full sheet nests and CNC punching, laser and press brake programs all ready to be downloaded to each specific machine from the server, maximising each machine’s full capabilities, producing all our metalwork to the tightest possible tolerances.”

With an annual turnover of £32m, KMF now has a workforce of around 420. Operations Director Keith Nichol says a typical contract starts with the customer’s order being loaded on to the system, taking its routing either through the design process or engineering planning process to give a method of manufacture and bill of materials, which are then translated into manufacture.

taking its routing either through the design process or engineering planning process to give a method of manufacture and bill of materials, which are then translated into manufacture.

“Radan provides everything we need to convert the design into machineable parts for the punches, lasers and press brakes, giving us accuracy and repeatability, whether the components are for Costa Coffee vending machines, point of sale material, kiosks, or for the medical sector. Lead times are typically between seven and 14 days, depending on the complexity of the products.”

He says Radan also plays a substantial role in KMF’s renowned apprenticeship programme. “Apprentices are an important part of the company’s future, gaining their skills in all the different parts of our operation. We have a Radan training license and CNC machine in the apprentice work shop, which is vital in helping them understand how to develop sheet metal parts with Radan, and how it programs CNC machine tools.”

Operating from a 120,000 square foot facility in Staffordshire, KMF Precision Sheetmetal Ltd ships around one million piece parts every month. Programming Manager Stephen Gardener says the Radnest function within their Radan sheetmetal CAD/CAM system from Vero Software saves time and reduces scrap.

“It plays a large part in our day to day business, and we use it in two different ways. Firstly, it consolidates large assemblies where we want to produce an exact amount of parts to match the Bill of Materials. A number of our assembly jobs consist of 100 or more parts, and the Project Nesting function means we can nest different materials and thicknesses on different sized sheets. These would typically be saved as a project, with all nests saved under one job number.

“And secondly, it gives us the ability to nest small batch quantities. If a customer wants five off, we can nest them on sheets with components for other customers. But if we had to run a full sheet program for just five parts it could leave us with about 20 per cent waste.

“And secondly, it gives us the ability to nest small batch quantities. If a customer wants five off, we can nest them on sheets with components for other customers. But if we had to run a full sheet program for just five parts it could leave us with about 20 per cent waste.“As our batch sizes can vary from one off to thousands off, we have a full time nesting office analysing all jobs to see if the quantity justifies running its own nest program. If it doesn’t, the parts will be separated and nested with parts for other customers. This way we can maximise sheet utilisation for any batch quantity.”

KMF have used Radan for many years to drive their range of Trumpf punch presses, punch/laser combination machine tools, and lasers. But a manual press brake operation for the bending process caused a considerable bottleneck with a typical set-up taking around 45 minutes. He says investing in Radan’s specialist Radbend module for programming press brakes has slashed set-up time by at least half. It also means they can frequently set up a job using just one part, saving save four or five parts on one set-up.

“And Radbend minimises waste by simulating the full bending sequence before starting to fold metal. Operators simply call up the program and view it in 3D on their machine console.”

Overall, KMF run Radraft, Radan 3D, Radprofile and Radpunch on a number of Trumpf machine tools, all fed with Stopa tower systems, and two of them using a ShearMaster to cut sheet skeletons. The CNC shop comprises three fully automated punches, two punch/laser combinations, and two lasers. And Radbend programs nine Trumpf press brakes, including a lifting arm on a 5130, which allows one operator to bend large panel work.

Their process with Radan begins by importing the 3D data, then determining the material properties and producing a flat development with bend allowance, which is sent straight to the profiling or tooling stage. “At this point we can also use Radraft to alter any details or features before tooling, and then add either laser profile or punch tools. We’d use auto tooling in both cases, and tweak manually if necessary, to optimise the tooling. Nesting ensures best sheet utilisation, and Radbend produces programs for the press brakes, either straight from the model or by Radraft’s ‘fold from flat’ feature.

“All this combines to give us full sheet nests and CNC punching, laser and press brake programs all ready to be downloaded to each specific machine from the server, maximising each machine’s full capabilities, producing all our metalwork to the tightest possible tolerances.”

With an annual turnover of £32m, KMF now has a workforce of around 420. Operations Director Keith Nichol says a typical contract starts with the customer’s order being loaded on to the system,

taking its routing either through the design process or engineering planning process to give a method of manufacture and bill of materials, which are then translated into manufacture.

taking its routing either through the design process or engineering planning process to give a method of manufacture and bill of materials, which are then translated into manufacture.“Radan provides everything we need to convert the design into machineable parts for the punches, lasers and press brakes, giving us accuracy and repeatability, whether the components are for Costa Coffee vending machines, point of sale material, kiosks, or for the medical sector. Lead times are typically between seven and 14 days, depending on the complexity of the products.”

He says Radan also plays a substantial role in KMF’s renowned apprenticeship programme. “Apprentices are an important part of the company’s future, gaining their skills in all the different parts of our operation. We have a Radan training license and CNC machine in the apprentice work shop, which is vital in helping them understand how to develop sheet metal parts with Radan, and how it programs CNC machine tools.”