Production software turns designs into reality for Daw Green clients

Daw Green Contracts Ltd. - U.K.

Contact us

To say that Alan Ruddock, Works Director of Daw Green Contracts Ltd., is passionate about the woodworking industry, would be an understatement.

He built his own workshop in a shed when he was 14, and had woodworking tools for Christmas as a child, taking his own full set of tools into his ‘O’ Level woodworking exam. And he fully admits that if you cut him, he’d bleed sawdust. “It was just born within me,” he says. “When I started working in the industry, I couldn’t believe I was getting paid to do something I loved so much.”

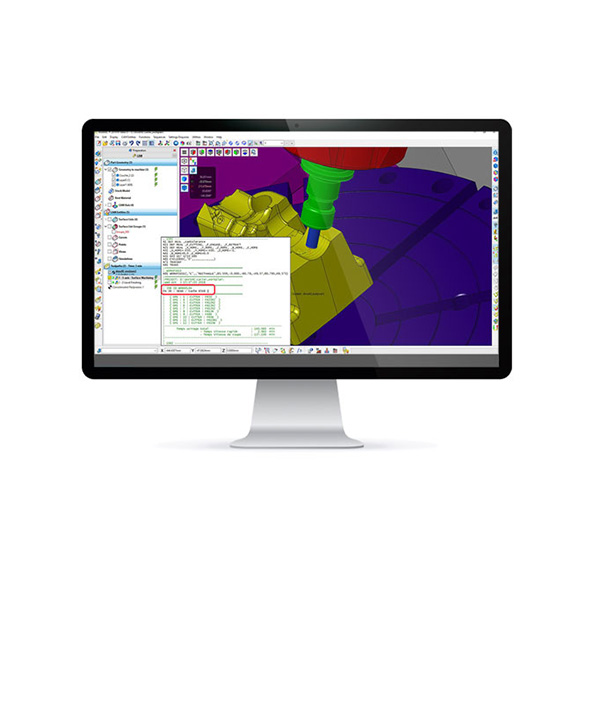

And now, he’s equally as passionate about ALPHACAM software which programs the company’s 3-axis SCM Record 125 router. As well as currently using ALPHACAM on every project the high-end shopfitting company works on, he is also expanding their use of CABINET VISION, which also drives the Record, through its Screen-To-Machine module.

Manufacturing everything from counters to displays, stands, wall panelling, ceiling features, desks and storage units, anything with a curved shape goes through ALPHACAM. “We’ve also had CABINET VISION for a few years, but only recently started to really exploit it for carcases and pure cabinetry components.”

Amongst their prestigious clients: the Trailfinders travel agency chain; Royalty, including Buckingham Palace, Holyrood Palace, Windsor Castle and Clarence House; and the Houses of Parliament.

“Because we only work at the real top end of the market, precision and quality is paramount for us. Our biggest challenge is the complexity of what we do, and with time being one of the major drivers of the industry, we’re always looking to save time, while still ensuring consistently high quality, particularly in the process of converting the original drawings into NC code for the machine tool. This is where CABINET VISION is starting to play an increasingly important role.”

When they first invested in CABINET VISION it was part of a period of considerable change for the company, and the software was underutilised. Now, while ALPHACAM will continue to program complex components, he says a lot of the case work is better suited to CABINET VISION.

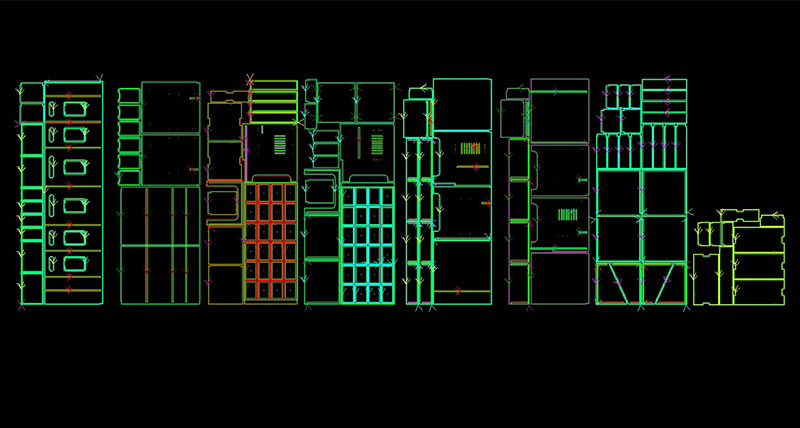

“The difference is, once we import our CAD drawings into ALPHACAM we have to break down the individual components and redraw them in ALPHCAM, then insert all the holes and fixings. But CABINET VISION produces the panels for us from the CAD drawings, and this will save us a tremendous amount of time, while reducing the risk of human error. Those drawings show the entire shop, including all the other trades – air conditioning, electrical, and flooring – and we extrapolate the cabinets, and treat them as individuals.”

He says further time savings come from CABINET VISION’s parametric function. “Basically we make boxes – a counter with cupboards and drawers is simply a box with other boxes inside, and as we’ve already invested time upfront with building up libraries and construction methods, we simply drag and drop a cabinet into the job, and when we edit one length, it automatically changes the other dimensions.

“Sometimes those boxes have complex shaped components, and we’ll need ALPHACAM to program those toolpaths, but the majority are now put directly through CABINET VISION now.”

As well as accuracy and time savings, he says CABINET VISION offers another huge benefit for the workshop: labelling. As well as the software producing drawings showing all the panels coming off the router, Label-IT enables their operator to clearly visualise the panels, print labels at the machine, and then simply place them on the parts as they’re nested out. The screen is updated automatically to show which parts and panels have been completed. Information on the labels includes the client name, job number, description, and edge banding details.

“This is particularly important for the shopfloor to take a pallet of parts and know which ones need to go to the edge bander, or directly to the bench for assembly as a finished counter or desk. It’s like putting a jigsaw puzzle together with the box lid picture, as opposed to doing it without the lid.”

In conclusion, Alan Ruddock says ALPHACAM has been valuable and integral to their processes for many years, and CABINET VISION is set to become of equal importance as they fully implement it. “The software turns designs into reality for our high-end customers. Without it, our production would simply stop.”