PDCA Cycle: methodology assists in achieving the best possible harvest

Created for quality management, a tool can also be applied in agribusiness and generate strategic results with the support of technology

Having strategically mapped planning makes all the difference for any type of business. It is no wonder that there is a saying that "those who plan sometimes make mistakes, and those who do not plan sometimes get it right". In agribusiness, it's no different. The absence of a plan to be followed or the lack of monitoring in its execution increase the chances of wasting resources, unnecessary expenses and failure to achieve the desired productivity.

"Currently, with so many technologies available to farmers and rural managers, a false impression is created that there will be maximum efficiency in any context. However, we should not follow that line. Innovations are, in fact, essential to achieving the best possible results. But, for this, it is necessary to know how to use them strategically," reinforces Bernardo de Castro, president of Hexagon's Agriculture division, which develops and provides digital solutions for agricultural and forestry productions.

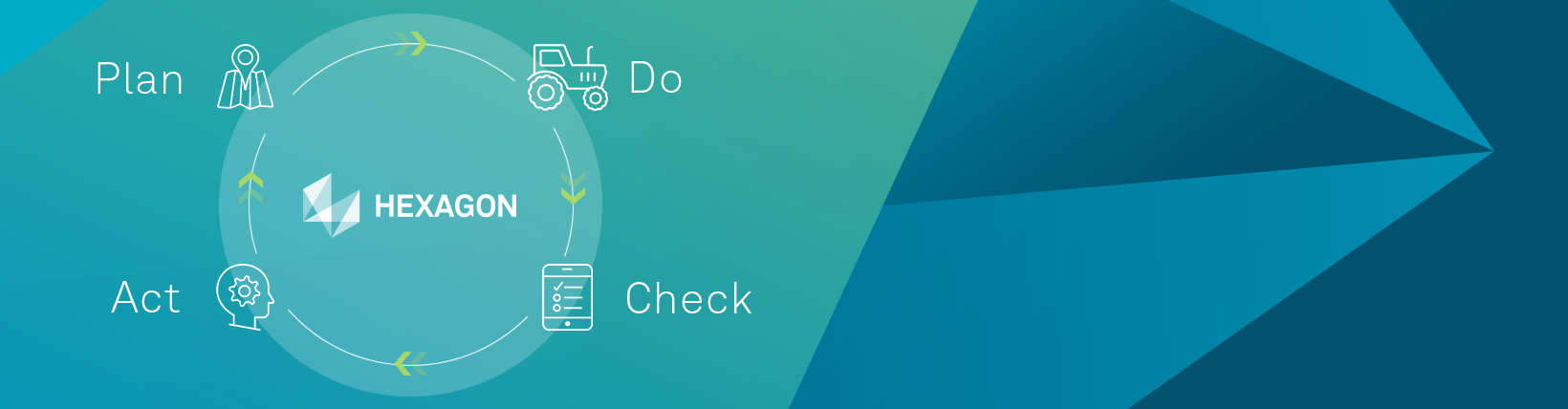

In this scenario, one of the tools that can be used in favour of agribusiness is the so-called PDCA Cycle — acronym for Plan, Do, Check and Act. This methodology was developed in the 1920s with the objective of being applied in the administration of management quality in industries, being recommended for companies to obtain continuous improvement in their products. Over the years, however, the cycle has been undergoing changes and expanding its initial purpose. Today, it is considered one of the most complete and efficient tools for managing any type of company — regardless of size or segment.

"The cycle seeks to bring continuous improvements in a company's processes, either through the implementation of new ideas or the solution of existing problems, with the objective of fulfilling pre-established goals. It is very common in areas such as people management and product development, but in agriculture, it is also able to bring enormous benefits," says Bernardo, who took the method into consideration when defining the portfolio of the company he commands. "Hexagon offers technologies to assist the rural manager at each stage of the cycle, ensuring complete integration of systems and, consequently, much more optimised management," he reinforces.

Check out how each step of the PDCA Cycle works and how they can be applied in agribusiness:

1 - Plan

The first step recommended by the PDCA Cycle is planning. As the name implies, during this period, the objective is to plan the activities that will be carried out, the necessary tools and the expected results. Within the scope of agribusiness, this includes issues such as the time of the operation, the machines, inputs and labour required, the expected expenses and the expected yield at the end of production.

To assist at this moment, the agricultural market already has software that allows short, medium and long-term planning, scaling investments and controlling costs, from soil preparation to the transportation of the harvested raw material. "With a planning tool, all the information necessary for a diagnosis of agricultural production is collected and crossed, generating a reliable plan to be followed," explains Bernardo. The technology reduces to a minimum the chances of unforeseen events that hinder the execution of the procedures and also guarantees the maximum use from the existing resources, reducing waste of inputs and even machine fuels.

2 - Do

The second phase is intended to put into practice everything that was planned, through the execution of the stipulated tasks. It is also important to be attentive to closely monitor this progress, ensuring that the activities happen as planned.

In the agricultural sector, it is possible to count on the support of machine automation technologies, such as auto steering and fertilisation and spraying controllers, to optimise this stage of the cycle. "Working with precision agriculture, the available solutions improve the performance of the machines and, through sensors, generate data that can be used in real time to adjust the operation," reinforces the president of Hexagon's Agriculture division.

3 - Check

The checking step can be carried out simultaneously or at the end of the actions. It is the time to monitor and measure each step of the operation, recording possible problems that interfered with the processes.

"To help check the PDCA Cycle in agribusiness, there are highly specialised technologies, capable of generating reports, graphs and detailed panels of everything that happens in the field," explains Bernardo. The information helps managers in making more assertive decisions and directs machine operators to the best execution.

4 - Act

Finally, despite being called “action,” the last stage of the PDCA Cycle is not necessarily related to the execution of the activities, but to the analysis and final management of the entire process. The idea is to reflect and evaluate the path that was followed, and then implement actions — whether continuous or corrective. If it is evaluated that the expected result was achieved, the working method used for the next productions can be adopted. On the other hand, if the expectations have not been fulfilled, one should seek the causes of the problem and, from that, start a new cycle seeking to solve them.

In agribusiness, operational management and business intelligence solutions connected to sensors and on-board computers of agricultural machinery allow the intelligent analysis of information such as working time, active hours and amount of fuel consumed. "They make it possible to generate reports and visions with consolidated data and compare what was planned with what was accomplished, helping in the elaboration of strategies for future improvements, which is exactly the proposal of the last part of the PDCA Cycle," emphasises the president of Hexagon's Agriculture division.