Parolin Stampi aims at continuous improvement in manufacturing sheet metal dies

by Alberto Marelli, Costruire Stampi - Reproduced with permission from Costruire Stampi, February 2021

Engineering Reality 2023 volume 2 edition

Empowering Makers for an autonomous sustainable future

Figure 1. Parolin Stampi’s headquarters are in Tezze sul Brenta, in Vicenza, Italy.

For over forty years, Parolin Stampi has specialised in manufacturing sheet metal dies and precision machining for various sectors, including automotive and household appliances

Parolin Stampi was founded in 1980 in Tezze sul Brenta in Vicenza, Italy, by Mr. Basilio Parolin. Initially specialising in constructing dies for the silverware sector, the company has grown and transformed to respond to the market’s needs.

“Until 2005, we worked in the silverware sector, then we joined the company,” explains Lodovico Parolin, who now heads the company with his brother Riccardo. “We decided to leave that sector to specialise in mechanical manufacturing and design and construction of stamping dies for cold working sheet metal, thus responding to the market’s needs.”

“These skills also translate into a proactive approach in the important co-design phase,” says Parolin. “An in-depth knowledge of materials and vast experience allows us to find the best solutions in creating and producing the finished product. This means the company can respond to our customers’ many needs, assisting them and accompanying them at every stage.”

“Today, the company has grown into three branches: the first deals with the design, construction, and testing of sheet metal dies (progressive, block, and transfer). The second branch deals with producing components using dies built by us or supplied by the customer on mechanical presses. Finally, the third branch deals with CNC milling machining from 3 to 5-axes,” underlines Parolin.

The Venetian company operates in various markets: from the automotive (brackets, supports, heat shields) to the household appliance (grates, hoods, drip pans for ovens, external casings for ovens and dishwashers), from furnishings to the building sector (components for gutters, supports for reinforcement, brackets for air conditioners, supports for photovoltaics). “Based on the size, we build about fifty dies a year, ranging from 500x500 up to 3,500x1,000 mm,” says Parolin.

Quality is at the heart of the business

All company activities are in the Tezze sul Brenta plant. The Mold Construction Division is equipped with state-of-the-art machines and systems, including three 3-axis machining centres, a continuous 5-axis milling machine and one with 5-indexed axes, a wire EDM system, two tangential grinding machines, and two parallel lathes displayed for making small components for the stamping die. All machines are networked, some of which work unattended.

“During the day, we machine the smallest components and carry out the finishing operations; at night and on weekends, we take care of roughing and machining with lower added value,” underlines Parolin. Inside the toolroom, each workstation is equipped with a personal computer from which it is possible, using Hexagon’s VISI Viewer, to view the die the operator is working on.

“In this way, the operator can see all changes any time the technical office makes them,” says Parolin. The milling department contacts the programming office (CAM), which generates all the toolpaths. Each CNC machine has tool changers, vices, and quick clamping systems for greater flexibility and higher productivity.

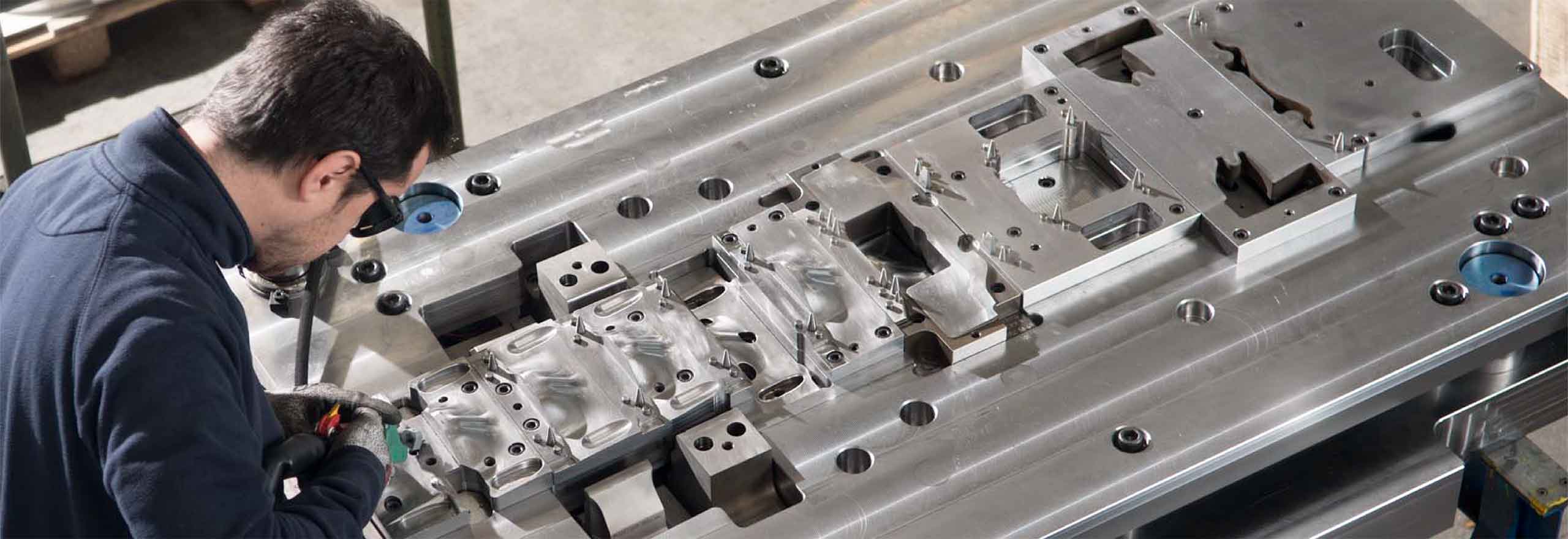

Figure 2. The Veneto-based company specializes in mechanical machining and the design/construction of molds for cold sheet metal working.

Figure 4. Parolin Stampi offers a complete service, from design to the creation of the finished piece.

Once the die’s construction is complete, the testing phase begins. The die is subjected to a series of tests to verify correct construction. A digital form is filled in at the end of each test, showing improvement interventions and changes to be made.

The stamping department has four mechanical presses ranging in size from 100 to 630 t. Parolin Stampi is a company that places great importance on quality. This commitment has allowed the company to obtain certification according to the UNI EN ISO 9001:2015 standard; to date, the company is working towards IATF certification specific to the automotive sector. “The constant search for high-quality standards is our main goal. In this regard, the metrology department constantly monitors our entire die construction and stamping process, equipped with a coordinate measuring machine,” underlines Parolin.

A company ready for the future

Parolin Stampi is making the concepts of Industry 4.0 a manufacturing reality. “We have been digitising the tool shop for some time now, eliminating paper,” explains Parolin. “We have also automated and networked the automatic vertical stock warehouse to avoid shortages of components needed for die assembly and processing the components themselves.”

He continues, “We operate a management system that oversees all production activities. The data flow is managed through software showing each component’s processing phase in real-time.”

All the tools necessary for the die maker

With the profound modernisation that Parolin Stampi has undergone in recent years, with the introduction of the latest generation CAD/CAM machines and systems, they place great importance on investment in training and updating their staff. “We take pride in communicating with our customers during every process stage. We use properly trained and qualified personnel and the most up-to-date software,” says Parolin. In the design activity, Hexagon’s VISI software is an essential technology for the Venetian company. “First of all, it is a system with very high capacity and potential but at the same time simple to use, both in the design and in the creation of the bill of materials,” explains Parolin.

The technical office has 5 VISI CAD stations with the VISI Modelling and VISI Progress modules since 2010. “We chose VISI because our customers in the area used this system, and the feedback was very positive. In fact, after a trial period, we had the confirmation that the software offers all the features necessary for the die maker’s work”, says Parolin. “The switch to VISI has brought significant benefits. In the construction of sheet metal dies, the software guarantees flexibility and speed in the design that a parametric system cannot ensure.

Figure 5. Progressive die designed and built by Parolin Stampi with VISI software.

Figure 6. Examples of stamped components for various industries made by Parolin Stampi.

For equipment that works the first time

VISI Progress software works with solids, surfaces, and wireframes without restrictions. The software is developed expressly for the design of progressive dies.

The variety of modelling functions, combined with surface editing, makes it easy to correct imported geometry that can be corrupted to build the most complex models from scratch. An advanced range of algorithms allows you to choose from different unfolding methods, from linear to complex. The most accurate algorithm determines the precise geometry locations for each operation by automatically shifting the location of the neutral fibre of the material. This shifting accounts for the material’s mechanical properties for determining the stretch and deformation of the geometry required for developing and unfolding the adjacent operations, all the way back to the precise blank shape. Starting from the explicit geometry of the piece part, you can quickly generate the strip design. The positioning and orientation of the part in the steps of the strip are automatic and optimised.

VISI Progress automatically supplies the values of the scrap, the position of the shearing centre of gravity, and the shearing and bending forces. In this way, it is possible to calculate the number and type of springs needed to open the die after each step, making it easier to design a fixture that works the first time.

As reported above, the Parolin Stampi technical office also uses the VISI Modelling module, a powerful modeller of solids and surfaces that combines the Parasolid market standard for solids with Vero technology for surfaces, analysis tools, and 2D drawing.

VISI Modelling offers complete flexibility in the construction, modification, or correction of complex 3D mathematics, all integrated into a single environment also shared by the other applications of the VISI family.

Solid modelling commands include subtraction, union, intersection, object seat, cavity, and fixed and variable radius fillets. Surface modelling features include 3, 4, or “n” sided patches, sliding surfaces in 1 or 2 directions with multiple generatrixes, and draft, tangent, tubular, ruled, and revolved surfaces. This great variety of modelling functions, combined with the surface editing function, makes it easy to correct imported geometries that can become corrupted and also to build the most complex models from scratch. The integrated management of the modelling environment with the machining one eliminates potential conversion errors and simplifies the entire design process. Simple menus and icons with context-sensitive online help make learning VISI Modelling quick and easy.

With the arrival of a new generation, the company has undergone a radical modernisation process in recent years, purchasing CAD/CAM software and the latest CNC machines.

However, their dedication to the people who contribute to the history of Parolin Stampi every day has remained unchanged.

“For us, competence and skill are key, and this is why we constantly invest in specific training,” adds Parolin. “Experience and state-of-the-art technological support allow us to offer complete service from design to production of the finished piece. This means we can respond to our customers’ many needs, assisting them and accompanying them in every stage.”