The need for speed making a flying legend fit for the 21st century

The Polen Special airplane

Contact us

You know you are looking at a piece of aviation history the moment you set your eyes on it. Its seductive, elegant lines, its smooth, flush-riveted body and the “get-out-of-myway” screaming red all bespeak of an unrelenting desire for speed. The Polen Special airplane, conceived and hand-built by Dennis Polen in 1972, is after all these years still one of the most revered homebuilt aircraft in the world.

At the beginning of the 1970s, available commercial sports airplanes either cost too much money or lacked in performance. Polen’s decision to build his own arose from that simple fact. Essentially a scaleddown WWII fighter minus the armament, the Polen Special, with its ground speed in excess of 300mph [480km/h] still makes it the fastest four-cylinder airplane around.

Very special

This airplane is literally one-of-a-kind. Efforts were made over the years to convince Polen to mass-produce his airplane or at least make its blueprints available, but he remained true to his commitment to keep the plane entirely to himself. After all, the Polen Special is not an airplane for amateur pilots. Intended to fly high and fly fast, the Special spends most of its air time in Class A airspace, above 18,000ft [approx. 5,500m] altitude under instrument flight rules and subject to air traffic control clearances and instructions, with the pilot breathing oxygen. Dennis Polen took enormous pride in having built such an amazing flying machine. Who could blame him for a little bit of pride of ownership?

Over the years, the Polen Special has achieved a truly “Classic” status among the aviation aficionados living in the American Pacific northwest, many of whom have their own Polen “sighting” story that inevitably involves seeing the plane‘s tail. As the years passed, the plane’s eminence only grew stronger. In 1997, Dennis Polen made the decision to sell the plane after no longer being able to fly it himself due to a chronic illness, but only under the condition that the plane be put into the capable hands of a pilot who was qualified enough to fly it safely and care for it lovingly. Enter Dick and Debbie Keyt from Granbury, TX.

Over the years, the Polen Special has achieved a truly “Classic” status among the aviation aficionados living in the American Pacific northwest, many of whom have their own Polen “sighting” story that inevitably involves seeing the plane‘s tail. As the years passed, the plane’s eminence only grew stronger. In 1997, Dennis Polen made the decision to sell the plane after no longer being able to fly it himself due to a chronic illness, but only under the condition that the plane be put into the capable hands of a pilot who was qualified enough to fly it safely and care for it lovingly. Enter Dick and Debbie Keyt from Granbury, TX.

A perfect match

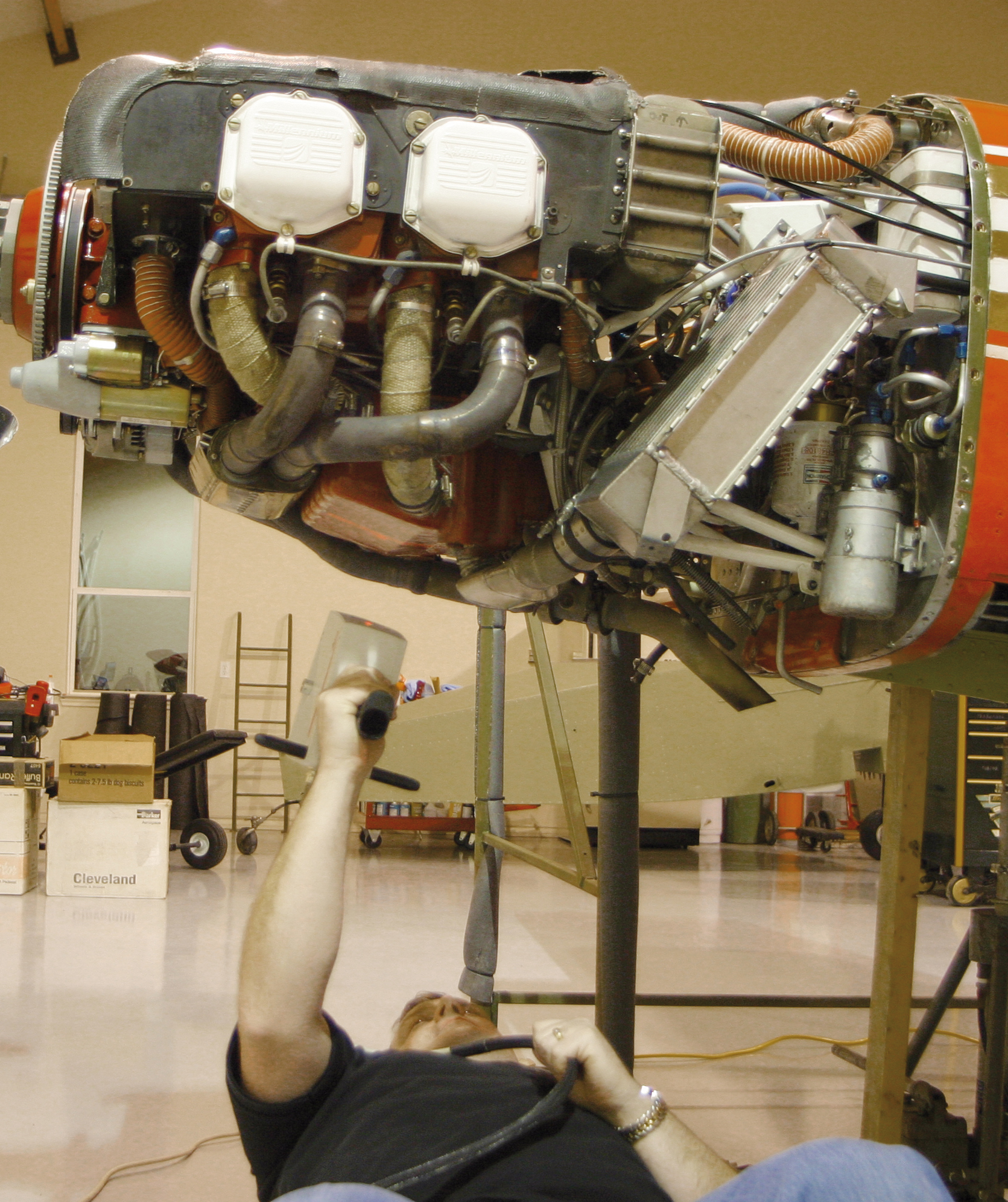

Dick Keyt is an active American Airlines pilot and an Air Force veteran with an aerospace engineering background. His wife Debbie is a former American Airlines flight attendant and a licensed pilot herself. If foster care for airplanes imposed a set of requirements, Dick and Debbie would pass by birthright. Upon assuming “guardianship” of the Polen Special and flying it at various air shows for several years, Keyt wanted to embark upon making modifications to the plane’s aerodynamics and powertrain but without chipping away at its soul. First, he wanted to redo some of the inefficient “plumbing” underneath the cowling (the sheeting covering the engine in the plane’s nose) and thus increase the power output of the engine. Second, Keyt wanted to redesign the cowling based on the new engine arrangement and improve aerodynamics. For the latter, he would team up with the University of Texas at Arlington (UTA) to do an aerodynamics analysis of the entire aircraft. For both of these tasks, Keyt needed to digitize large segments of his plane.

Leica T-Scan comes into play

For both of these tasks, Leica T-Scan, a high-speed hand scanner, paired to a Leica LTD700 Laser Tracker, was selected because it ideally matched the requirements set for the job at hand. Denny Deegan, a Leica Geosystems Application Engineer from Wichita, KS, drove down to Granbury to perform the job. Leica T-Scan offers three crucial advantages when compared to similar scanning solutions: it is virtually impervious to environmental light and the type of surface being scanned, requiring no surface preparation in most cases. In addition, Leica T-Scan operates in a measurement volume of up to 98ft [30m], allowing for the entire airplane to be scanned with just rudimentary repositioning of the equipment involved.

On top of that, the point-cloud data collected by the Leica T-Scan requires no post-processing to generate a 3D rendition of the scanned object; all data is processed in real time right there on the spot, and is immediately usable. Because of the Leica T-Scan’s clear advantage over similar scanning solutions, Denny scanned the entire plane in merely 16 hours, gathering over 32 million data points. This is a saving of several days when compared to other scanning solutions that require extensive surface preparation and massive post-processing of data. Dick Keyt was able to follow the progress of the scanning job in real time on an application computer running the T-Collect software from Steinbichler, seeing scanned engine segments in real-time on a PC screen just as they were being digitized. Various improvement ideas kept popping up in his head almost as quickly as Denny Deegan was able to scan different surfaces.

From points to surfaces

One idea Keyt had was to create a digital copy of the aircraft that would be usable in CAD/CAM software for replicating the shape of the aircraft. “In the eventuality of a crash, there would always be a 3D model on hand that could be used to manufacture and reconstruct missing parts..” To create a 3D model usable for CAD/CAM applications, the data obtained with the Leica T-Scan was imported into the PolyWorks software suite, the leading point cloud processing solution developed by the Canadian company InnovMetric Software, to create a polygonal model. With advanced algorithms, PolyWorks averaged all data points and merged them together to create an accurate meshed model. Then, the model was cleaned and edited using PolyWorks editing tools. Finally, the model was exported in STL format and can now be used for applications such as rapid-prototyping and CFD analysis. For further applications in CAD/CAM software suites, specialists created NURBS surfaces from the polygonal model within the PolyWorks/Modeler module. These surfaces were exported in the IGES format to SolidWorks, a CAD software, to conduct a detailed analysis of the possibility of modifying the air flow management system of the air plane.

Sleeker, faster, higher

One of the uses for this data will be to design a plenum chamber on top of the engine that would seal all of the air coming into the front inlets and would be independent of the cowling itself,” explains Dick Keyt. “The new plenum chamber will be completely embedded inside the cowling. This will optimize the air flow management in the engine, letting us squeeze more power out of it. The more power I have at my disposal, the harder I can push the plane. This is what reverse engineering is all about.” Another major improvement that will be possible after having a fully digitized rendering of the engine bay is to reposition the ductwork bringing the outside air into the turbo charger. Keyt continues:

“Based on the 3D renderings of the engine, we will figure out how much depth we have and what the clearances are off the exhaust pipes. In the current design, the turbo charger has to suck the air in. If we can ram the air into the turbo charger instead, we could lower the discharge temperature, giving us higher performance. Right now, the intercooler cools the air coming out of the charger down from 300 degrees Fahrenheit [150°C] to 200 degrees Fahrenheit [93°C]. This is very thin air, with comparably little oxygen to burn. The cooler we get the air, the denser it gets, increasing the oxygen content significantly.

The more oxygen there is to burn, the more fuel can you pump into the combustion chamber, increasing the horsepower output. We hope to be able to drop the air temperature further to about 150 degrees Fahrenheit [65°C].” The second important design change will be to design a new cowling based on the new engine component arrangement. “I will team up with UTA, with benefits for both parties.

The more oxygen there is to burn, the more fuel can you pump into the combustion chamber, increasing the horsepower output. We hope to be able to drop the air temperature further to about 150 degrees Fahrenheit [65°C].” The second important design change will be to design a new cowling based on the new engine component arrangement. “I will team up with UTA, with benefits for both parties.

The university gets excellent raw data for teaching purposes; as far as I know, there have been just isolated cases of entire planes being digitized. In return, the university will allow me to pinpoint where airflow interferences are and how we can make the cowling more efficient, concludes Keyt.

To analyze the possibility of repositioning the ductwork and adding a new cowling system, Leica Geosystems and InnovMetric software teamed up to create a virtual assembly using the digitized models of the engine and front fuselage. Using powerful alignment techniques, the polygonal model of the engine was virtually assembled in the engine compartment.

With full 3D rendering, it was then possible to use the PolyWorks/Inspector module to measure dimensions and distances between each components. Finally, the geometry of the actual piping system was extracted and exported in IGES format to the SolidWorks CAD software for design modifications. With the exact dimensions and location of the components in place, it was possible to design a new pipe in SolidWorks to bring outside air into the turbo charger. “Leica Geosystems has always been keenly aware of the importance of exposing the academia to real-world problems,” expands Denny Deegan.

“Recognizing the intrinsic value of applied research, we were more than pleased to donate our resources and time in order to bring the Polen Special project to life.” All these improvements are intended to increase the airplane‘s already impressive aerodynamics and power output, letting Keyt fly his “Special” at higher altitudes and at greater speeds. These improvements will make sure the plane remains competitive in the sport aviation field in the years to come, living up to Dennis Polen’s legacy and exposing this important piece of aviation history to even more flying enthusiasts.

About Polen Special

The Polen Special was a creation of Dennis Polen with the help of his two friends, Jim Hergert and Darryl Usher. The project began in 1967 and the aircraft‘s first flight was in May 1972. The effort was similar of that to the Wright Brothers in that the project was undertaken by individuals, with no corporate assistance or financial help. The final assembly was in Dennis‘s two car garage in Portland, Oregon. The aircraft was turbo charged in the mid 1970s, but Dennis removed the turbo because it was difficult to manage. He found that flying the plane was not as much fun because the system required so much pilot attention. Since Dick Keyt‘s acquisition of the “Special,” he has worked on reliability while returning the plane to its early performance. In July 2001 the Polen Special established a new world speed record for the FAI/NAA Class c1 310mi [500km] closed course. The old record set by Rich Gritter in a Questair Venture with a 280hp engine was at a speed of 284mph [457km/h]. The Polen speed for this record was 303.5mph [487km/h] with only 180hp.