Manufacturing versatility

Faist Mekatronic - Romania

Contact us

Hexagon Manufacturing Intelligence helps component manufacturer deal with diverse customer demands.

With time to market an increasingly important differentiator for manufacturers, building a reliable supply chain has never been more essential. These pressures are particularly prevalent in fast-moving sectors such as consumer electronics, or even in the highly competitive automotive field. For suppliers to these industries, the challenge is to deliver a hugely diverse range of components, correctly and on time, every time. One company that knows these challenges extremely well is Faist Mekatronic, a key supplier for the telecom and automotive industries. Established in 2005 and located in Oradea, Romania, Faist Mekatronic is one of the 24 globally-located sites that make up multinational manufacturing powerhouse FAiST Group. Since FAiST Group was founded in 1978, it has grown consistently and now has over 2,500 employees worldwide.

Faist Mekatronic sits within the Light Metal Components business unit, which specialises in R&D, new product introduction and component manufacturing processes including aluminium die casting, precision machining and surface plating. The business prides itself on its reputation for innovation and quality, and utilises its global footprint and expertise to reinforce both. “An innovative product is only successful when it is based on reliable concepts and technologies,” explains Lucian Scurtu, Metrology Responsible at Faist Mekatronic. Our products are typically die-cast parts with complex geometries and we have to ensure correct dimensional results.

The difficulty is that our applications are extremely diverse, so when we select our measurement equipment, we need a degree of versatility as well as accuracy and reliability. We always say that staying competitive requires flexible thinking, and this is why we chose a technology solution provider like Hexagon Manufacturing Intelligence.

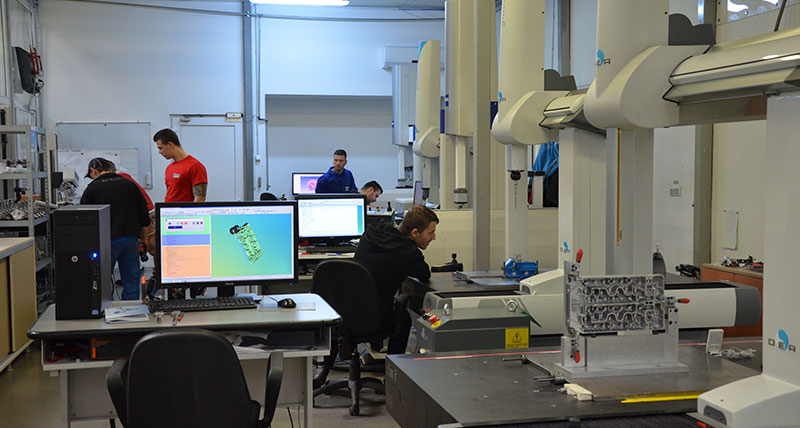

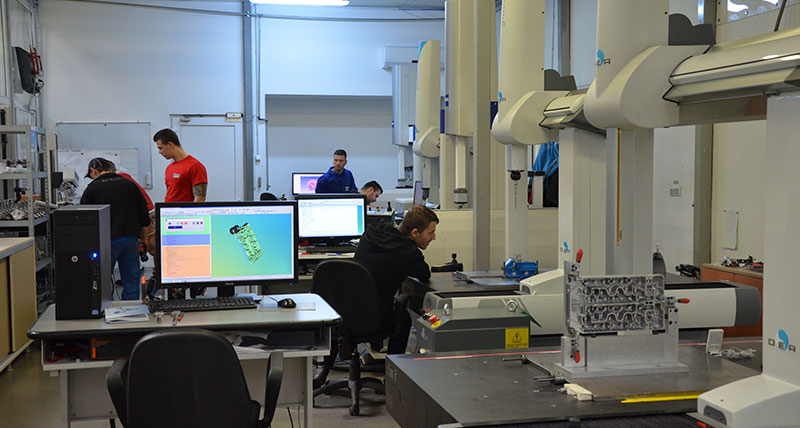

”Faist Mekatronic bought its first Hexagon Metrology device, a GLOBAL coordinate measuring machine (CMM), in 2006, just a year after the company was founded. Since then, it has increased its measurement capabilities in line with business requirements.

The company has enjoyed continuing growth and now boasts four GLOBAL CMMs with PC-DMIS CAD++ software, giving operators the ability to accurately inspect all kinds of components and assemblies.

“The drawings we are working to can be very complex and therefore we need to use geometric dimensioning and tolerancing (GD&T).

“On a day-to-day basis we are checking things like surface profile, flatness, true position, location, angularity, perpendicularity, circularity, symmetry, parallelism and so on. Our set ups change continuously; depending on the customer we could be measuring power train components, filter housings, covers, plates, thermal controls, pumps, electronic motors, all kind of things.

It’s a big task, but our CMMs give us the capabilities we need. The machines are equipped with active dampers to keep their top performance even in presence of strong floor vibrations. We also chose to add options like tool changers and additional scanning probes to further enhance what is already very flexible equipment.”

The difficulty is that our applications are extremely diverse, so when we select our measurement equipment, we need a degree of versatility as well as accuracy and reliability. We always say that staying competitive requires flexible thinking, and this is why we chose a technology solution provider like Hexagon Manufacturing Intelligence.

”Faist Mekatronic bought its first Hexagon Metrology device, a GLOBAL coordinate measuring machine (CMM), in 2006, just a year after the company was founded. Since then, it has increased its measurement capabilities in line with business requirements.

The company has enjoyed continuing growth and now boasts four GLOBAL CMMs with PC-DMIS CAD++ software, giving operators the ability to accurately inspect all kinds of components and assemblies.

“The drawings we are working to can be very complex and therefore we need to use geometric dimensioning and tolerancing (GD&T).

“On a day-to-day basis we are checking things like surface profile, flatness, true position, location, angularity, perpendicularity, circularity, symmetry, parallelism and so on. Our set ups change continuously; depending on the customer we could be measuring power train components, filter housings, covers, plates, thermal controls, pumps, electronic motors, all kind of things.

It’s a big task, but our CMMs give us the capabilities we need. The machines are equipped with active dampers to keep their top performance even in presence of strong floor vibrations. We also chose to add options like tool changers and additional scanning probes to further enhance what is already very flexible equipment.”

As well as combining accuracy, flexibility and reliability, Hexagon’s broad portfolio has enabled Faist Mekatronic to continually scale their equipment to match business needs. Recently the company started using the ROMER Absolute Arm with HP-L-20.8 laser scanner.

This portable inspection solution can be used anywhere in the workshop and provides rich data about both casting die setups and die-cast parts. Together with its leading dimensional metrology software package, the ROMER Absolute Arm enables quick yet comprehensive pointcloud processing for immediate feedback, ensuring speed and confidence throughout the process.

As well as combining accuracy, flexibility and reliability, Hexagon’s broad portfolio has enabled Faist Mekatronic to continually scale their equipment to match business needs. Recently the company started using the ROMER Absolute Arm with HP-L-20.8 laser scanner.

This portable inspection solution can be used anywhere in the workshop and provides rich data about both casting die setups and die-cast parts. Together with its leading dimensional metrology software package, the ROMER Absolute Arm enables quick yet comprehensive pointcloud processing for immediate feedback, ensuring speed and confidence throughout the process.

“We chose Hexagon because the company is a top supplier of products and services in the 3D measurement field and beyond. We also use Q-DAS statistical process control software, and we have excellent technical support, maintenance and training from Hexagon’s authorised dealer in Romania – Micro-Top. It’s this ability to offer complete and comprehensive solutions across the whole manufacturing spectrum that makes Hexagon such a valuable partner,” concludes Lucian Scurtu. “I don’t think I could even begin to quantify how much time and money our measurement systems have saved over the last decade, but for sure we couldn’t have reached today’s level of development and performance without our partnership with Hexagon Manufacturing Intelligence.”

With time to market an increasingly important differentiator for manufacturers, building a reliable supply chain has never been more essential. These pressures are particularly prevalent in fast-moving sectors such as consumer electronics, or even in the highly competitive automotive field. For suppliers to these industries, the challenge is to deliver a hugely diverse range of components, correctly and on time, every time. One company that knows these challenges extremely well is Faist Mekatronic, a key supplier for the telecom and automotive industries. Established in 2005 and located in Oradea, Romania, Faist Mekatronic is one of the 24 globally-located sites that make up multinational manufacturing powerhouse FAiST Group. Since FAiST Group was founded in 1978, it has grown consistently and now has over 2,500 employees worldwide.

Faist Mekatronic sits within the Light Metal Components business unit, which specialises in R&D, new product introduction and component manufacturing processes including aluminium die casting, precision machining and surface plating. The business prides itself on its reputation for innovation and quality, and utilises its global footprint and expertise to reinforce both. “An innovative product is only successful when it is based on reliable concepts and technologies,” explains Lucian Scurtu, Metrology Responsible at Faist Mekatronic. Our products are typically die-cast parts with complex geometries and we have to ensure correct dimensional results.

The difficulty is that our applications are extremely diverse, so when we select our measurement equipment, we need a degree of versatility as well as accuracy and reliability. We always say that staying competitive requires flexible thinking, and this is why we chose a technology solution provider like Hexagon Manufacturing Intelligence.

”Faist Mekatronic bought its first Hexagon Metrology device, a GLOBAL coordinate measuring machine (CMM), in 2006, just a year after the company was founded. Since then, it has increased its measurement capabilities in line with business requirements.

The company has enjoyed continuing growth and now boasts four GLOBAL CMMs with PC-DMIS CAD++ software, giving operators the ability to accurately inspect all kinds of components and assemblies.

“The drawings we are working to can be very complex and therefore we need to use geometric dimensioning and tolerancing (GD&T).

“On a day-to-day basis we are checking things like surface profile, flatness, true position, location, angularity, perpendicularity, circularity, symmetry, parallelism and so on. Our set ups change continuously; depending on the customer we could be measuring power train components, filter housings, covers, plates, thermal controls, pumps, electronic motors, all kind of things.

It’s a big task, but our CMMs give us the capabilities we need. The machines are equipped with active dampers to keep their top performance even in presence of strong floor vibrations. We also chose to add options like tool changers and additional scanning probes to further enhance what is already very flexible equipment.”

The difficulty is that our applications are extremely diverse, so when we select our measurement equipment, we need a degree of versatility as well as accuracy and reliability. We always say that staying competitive requires flexible thinking, and this is why we chose a technology solution provider like Hexagon Manufacturing Intelligence.

”Faist Mekatronic bought its first Hexagon Metrology device, a GLOBAL coordinate measuring machine (CMM), in 2006, just a year after the company was founded. Since then, it has increased its measurement capabilities in line with business requirements.

The company has enjoyed continuing growth and now boasts four GLOBAL CMMs with PC-DMIS CAD++ software, giving operators the ability to accurately inspect all kinds of components and assemblies.

“The drawings we are working to can be very complex and therefore we need to use geometric dimensioning and tolerancing (GD&T).

“On a day-to-day basis we are checking things like surface profile, flatness, true position, location, angularity, perpendicularity, circularity, symmetry, parallelism and so on. Our set ups change continuously; depending on the customer we could be measuring power train components, filter housings, covers, plates, thermal controls, pumps, electronic motors, all kind of things.

It’s a big task, but our CMMs give us the capabilities we need. The machines are equipped with active dampers to keep their top performance even in presence of strong floor vibrations. We also chose to add options like tool changers and additional scanning probes to further enhance what is already very flexible equipment.” As well as combining accuracy, flexibility and reliability, Hexagon’s broad portfolio has enabled Faist Mekatronic to continually scale their equipment to match business needs. Recently the company started using the ROMER Absolute Arm with HP-L-20.8 laser scanner.

This portable inspection solution can be used anywhere in the workshop and provides rich data about both casting die setups and die-cast parts. Together with its leading dimensional metrology software package, the ROMER Absolute Arm enables quick yet comprehensive pointcloud processing for immediate feedback, ensuring speed and confidence throughout the process.

As well as combining accuracy, flexibility and reliability, Hexagon’s broad portfolio has enabled Faist Mekatronic to continually scale their equipment to match business needs. Recently the company started using the ROMER Absolute Arm with HP-L-20.8 laser scanner.

This portable inspection solution can be used anywhere in the workshop and provides rich data about both casting die setups and die-cast parts. Together with its leading dimensional metrology software package, the ROMER Absolute Arm enables quick yet comprehensive pointcloud processing for immediate feedback, ensuring speed and confidence throughout the process.

“We chose Hexagon because the company is a top supplier of products and services in the 3D measurement field and beyond. We also use Q-DAS statistical process control software, and we have excellent technical support, maintenance and training from Hexagon’s authorised dealer in Romania – Micro-Top. It’s this ability to offer complete and comprehensive solutions across the whole manufacturing spectrum that makes Hexagon such a valuable partner,” concludes Lucian Scurtu. “I don’t think I could even begin to quantify how much time and money our measurement systems have saved over the last decade, but for sure we couldn’t have reached today’s level of development and performance without our partnership with Hexagon Manufacturing Intelligence.”