Inspection of aircraft ribs, hinges and machined parts

Solutions for the dimensional measurement of large-scale aerospace components close to production

Contact us

An aircraft’s safety depends on the quality and fit of the thousands of machined parts that make up its structure. They can be challenging to inspect on the shop floor, however, either because of their volume or because of their intricacy.

The hinges that articulate the wing flap panels of an aircraft’s flight control surfaces, for example, have a complex geometry that demands a flexible, high performance inspection tool. And the ribs of an aircraft’s wings and centre wing box require a measurement system that can quickly and accurately accommodate their large proportions.

Some aircraft part inspections demand a CMM that can measure large dimensional complex geometries, others require a flexible and highly-accurate measurement system that can be installed close to the production line to improve the manufacturing cycle time.

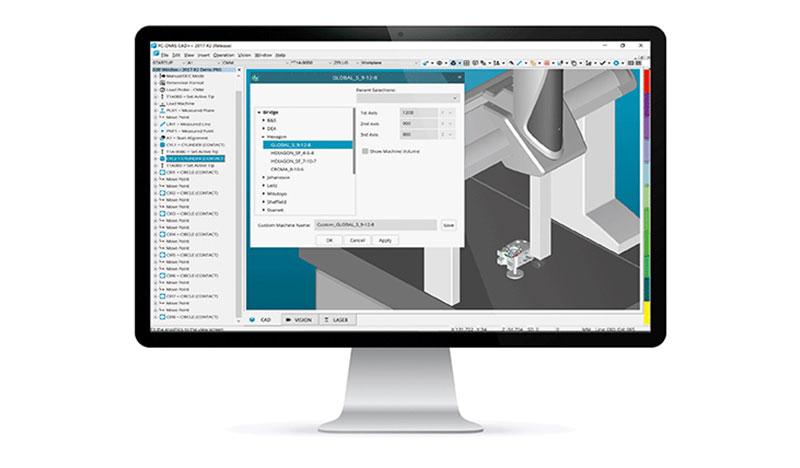

Hexagon provides a range of quality control solutions designed to meet the demands of large-volume measurement in the aerospace industry. Our highly efficient horizontal-arm CMMs guarantee the flexible, in-process inspection of large parts and are rugged enough to operate on the shop floor. Our bridge CMM ranges feature high machine dynamics, thermal compensation and a wide variety of probe configurations, making them easy to configure for aerospace components with tight tolerances and complex geometries. And whichever tool you use, Hexagon’s world-leading metrology software ensures its operation is simple and intuitive.