Hotel conversion makes the news with ALPHACAM

HOLZ-HER says ALPHACAM is the industry “go-to” CAM package

Contact us

A bespoke traditional joinery company operating at the high end of the woodworking market has recently been involved in a major conversion project, turning the former offices of the Coventry Telegraph newspaper into a luxury 1970s themed hotel.

LOL Summers Joinery Ltd.’s work on the conversion included slotted headboards, panelling, bedside tables and wardrobes in 88 bedrooms, along with seating in ten areas, and fittings for two bars and reception.

It is one of three companies in the woodworking industry owned by Lee Summers. The others are RHA Production, focusing more on fitted furniture; and 5-Axis Routing Ltd., which serves the CNC requirements of the other two, as well as standing alone as an independent subcontractor.

“We provide bespoke, high end traditional joinery, and have worked with universities and schools. We’ve also manufactured shop fronts for supermarket chains such as Tesco, the Co-Op, and Sainsburys all over the country,” says Lee Summers. While Summers Joinery was contracted for the hotel conversion, 5-Axis Routing provided all CNC aspects for their component parts, and drawing elements for approval.

And, as the name of his CNC company suggests, Lee Summers believes wholeheartedly in the huge benefits of 5-axis routing, compared to 3-axis. All their machined components are cut on a HOLZ-HER Dynestic router, with a 2.2 x 4.6 metre bed and in- and out-feed tables, programmed with ALPHACAM Ultimate software. “That combination gives us the ability to do a variety of work without the need for specialist cutters. We produce key, high end, complex shapes, accurately machined in the shortest possible time. So, we’re not looking to put ourselves in the same sector as the 3-axis market.”

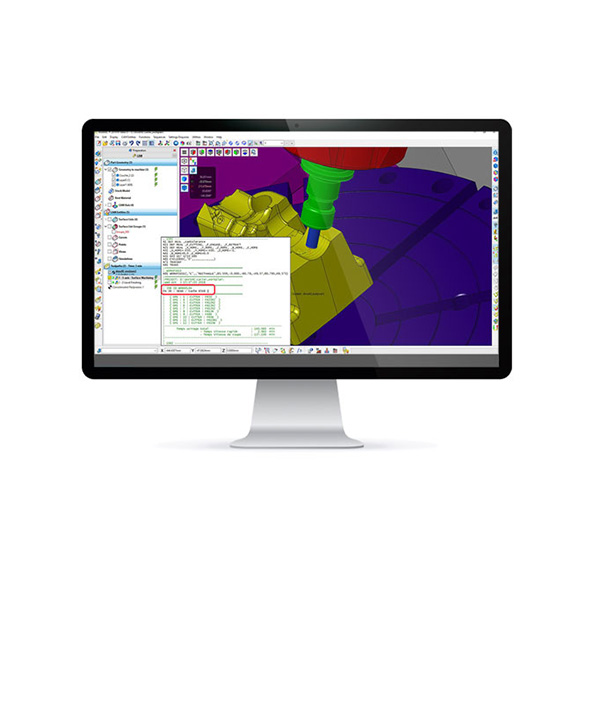

He says: “ALPHACAM is geared up for the ultimate bespoke manufacturer, which is us. Without it, we couldn’t do what we do. We started by using it for just a few hours every couple of days. Now it’s completely integrated into our processes and we work with it nine or ten hours every day. Prior to investing in ALPHACAM we programmed the router with its proprietary software, which is excellent at what it does, but was too simplistic for our bespoke needs.”

The company has an experienced ALPHACAM programmer in Alex McCann, who uses its Automation Manager function to work on solid models from Autodesk Inventor, and automate processes through its range of advanced tools, including machining styles. In a conventional CAM system, each file would be processed individually by inserting the file, extracting the features, applying tool directions and toolpaths, saving the file and NC code, and then generating the required reports.

Automation Manager carries out those repetitive tasks automatically. 2D and 3D Cad files, along with solid models from third party software, are batch processed, from file preparation right through to applying toolpaths, with NC code being generated automatically.

Lee Summers’ points, both about about 5-axis cutting and ALPHACAM, are shared by Paul Nightingale, National Sales Manager for HOLZ-HER UK. “5-axis machining offers a world of possibilities – it returns a robust, flexible, direct driven head with no need for aggregates. It saves on time because it’s easier than programming for aggregate use. And, as well as requiring fewer cutting tools, tool life can be extended, depending on the operation.”

He says the key for coming up with the correct package for 5-Axis Routing Ltd. was to understand their aspirations and their ‘pain.’ “We’re not just selling a machine tool. We’re providing a complete solution, including software, training, and service back-up to remove the company’s pain and challenges, and deliver their goals in terms of quality, productivity, longevity, reliability, and return on investment.”

In Lee Summers’ case, those challenges had been customers demanding higher quality parts with increasingly faster turnaround times.

The issue had been whether they needed a pod and rail machine or flat bed. Working collaboratively with Lee Summers, he established that the Dynestic flat bed was the perfect solution for enhancing productivity to their simplified production process, while maintaining their high level of creativity.

And he concludes by saying: “Being the ‘go-to’ CAM package for the industry, ALPHACAM is the perfect CAM system to drive it. The software is extremely stable and exceptionally powerful, and works seamlessly with our open architecture, NC-HOPS. It fits perfectly with the synergy of top quality machine and personnel at Summers Joinery.”

LOL Summers Joinery Ltd.’s work on the conversion included slotted headboards, panelling, bedside tables and wardrobes in 88 bedrooms, along with seating in ten areas, and fittings for two bars and reception.

It is one of three companies in the woodworking industry owned by Lee Summers. The others are RHA Production, focusing more on fitted furniture; and 5-Axis Routing Ltd., which serves the CNC requirements of the other two, as well as standing alone as an independent subcontractor.

“We provide bespoke, high end traditional joinery, and have worked with universities and schools. We’ve also manufactured shop fronts for supermarket chains such as Tesco, the Co-Op, and Sainsburys all over the country,” says Lee Summers. While Summers Joinery was contracted for the hotel conversion, 5-Axis Routing provided all CNC aspects for their component parts, and drawing elements for approval.

And, as the name of his CNC company suggests, Lee Summers believes wholeheartedly in the huge benefits of 5-axis routing, compared to 3-axis. All their machined components are cut on a HOLZ-HER Dynestic router, with a 2.2 x 4.6 metre bed and in- and out-feed tables, programmed with ALPHACAM Ultimate software. “That combination gives us the ability to do a variety of work without the need for specialist cutters. We produce key, high end, complex shapes, accurately machined in the shortest possible time. So, we’re not looking to put ourselves in the same sector as the 3-axis market.”

He says: “ALPHACAM is geared up for the ultimate bespoke manufacturer, which is us. Without it, we couldn’t do what we do. We started by using it for just a few hours every couple of days. Now it’s completely integrated into our processes and we work with it nine or ten hours every day. Prior to investing in ALPHACAM we programmed the router with its proprietary software, which is excellent at what it does, but was too simplistic for our bespoke needs.”

The company has an experienced ALPHACAM programmer in Alex McCann, who uses its Automation Manager function to work on solid models from Autodesk Inventor, and automate processes through its range of advanced tools, including machining styles. In a conventional CAM system, each file would be processed individually by inserting the file, extracting the features, applying tool directions and toolpaths, saving the file and NC code, and then generating the required reports.

Automation Manager carries out those repetitive tasks automatically. 2D and 3D Cad files, along with solid models from third party software, are batch processed, from file preparation right through to applying toolpaths, with NC code being generated automatically.

Lee Summers’ points, both about about 5-axis cutting and ALPHACAM, are shared by Paul Nightingale, National Sales Manager for HOLZ-HER UK. “5-axis machining offers a world of possibilities – it returns a robust, flexible, direct driven head with no need for aggregates. It saves on time because it’s easier than programming for aggregate use. And, as well as requiring fewer cutting tools, tool life can be extended, depending on the operation.”

He says the key for coming up with the correct package for 5-Axis Routing Ltd. was to understand their aspirations and their ‘pain.’ “We’re not just selling a machine tool. We’re providing a complete solution, including software, training, and service back-up to remove the company’s pain and challenges, and deliver their goals in terms of quality, productivity, longevity, reliability, and return on investment.”

In Lee Summers’ case, those challenges had been customers demanding higher quality parts with increasingly faster turnaround times.

The issue had been whether they needed a pod and rail machine or flat bed. Working collaboratively with Lee Summers, he established that the Dynestic flat bed was the perfect solution for enhancing productivity to their simplified production process, while maintaining their high level of creativity.

And he concludes by saying: “Being the ‘go-to’ CAM package for the industry, ALPHACAM is the perfect CAM system to drive it. The software is extremely stable and exceptionally powerful, and works seamlessly with our open architecture, NC-HOPS. It fits perfectly with the synergy of top quality machine and personnel at Summers Joinery.”