High-speed scanning

3D digitisation with Hexagon’s high-end metrology tools

Contact us

The complexity of a race vehicle requires extraordinary levels of accuracy, making the construction process crucial when collecting results. Hexagon Manufacturing Intelligence subjected the single-seater from Madrid Polytechnic University (UPM) to a complete and fast analysis.

When it comes to achieving success in any competition, the skill, training and passion of the pilot are key, but so is the quality, accuracy and reliability of the vehicle. This is the cocktail of factors that will be subjected to the maximum demands of racing.

The single-seater from the Madrid Polytechnic University team competes at an international level in the Formula Student category, putting the ability of the engineering students and the accuracy with which they’re able to develop first-rate vehicles to the test.

The single-seater from the Madrid Polytechnic University team competes at an international level in the Formula Student category, putting the ability of the engineering students and the accuracy with which they’re able to develop first-rate vehicles to the test.

Among motors of comparable performance (up to 600 cc), the perfection of the components, from production and assembly through to aerodynamics, are defining factors. “The power of all the vehicles is similar, making weight reduction is very interesting, as well as the necessity to keep the centre of gravity as low and centred as possible”, said Ramón Martínez Valdivia, Marketing Manager at UPM.

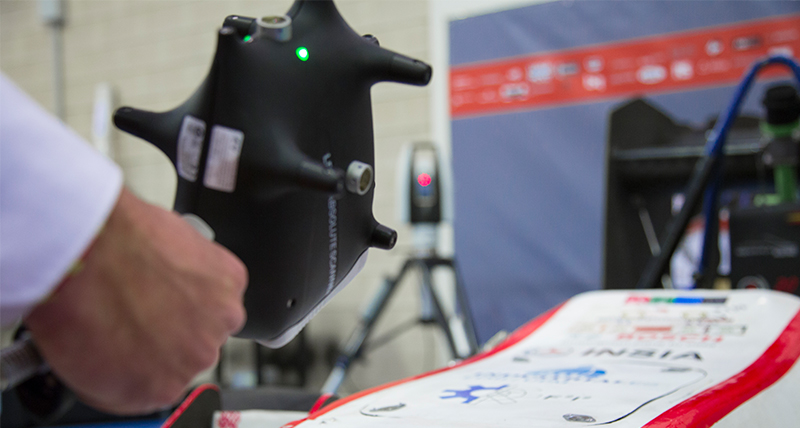

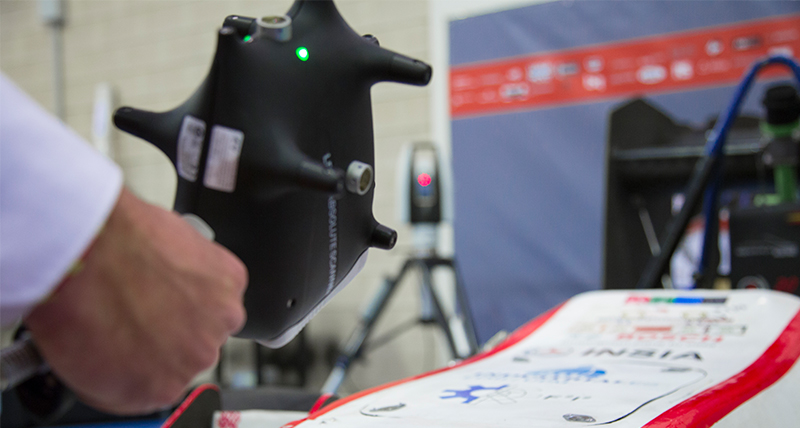

The Leica Absolute Tracker AT960 combined with the Leica Absolute Scanner LAS-20-8 allowed the vehicle to be measured in a very short period while still achieving a measurement uncertainty of less than 50 µm. The result of the scanning work was a transverse model of the vehicle that allowed the team to develop a range of applications: “They were able to perform aerodynamic calculations in addition to suspension modifications, notably improving their times in the next Formula Student race”, noted Sergio Herradura, Sales Engineer and Specialist in the Hexagon Manufacturing Intelligence Portable Product Line.

been made. In order to do this, we rely on Hexagon technology to determine deviations and how they affect both the design and the resistance of the piece and the car's dynamics”, said David Ángel Fernández, Chief Engineer at UPM.

been made. In order to do this, we rely on Hexagon technology to determine deviations and how they affect both the design and the resistance of the piece and the car's dynamics”, said David Ángel Fernández, Chief Engineer at UPM.

The use of the Leica Absolute Scanner LAS-20-8 was crucial for analysing the disparity between some elements. Using the accurate data gathered from the scanner point clouds, the UPM team were able to pay special attention to the areas that made the most difference. “Among the great advantages of the scanner is its ease of use and lightness in combination with the high performance it achieves. It‘s allowed us to improve our manufacturing process while taking into account tolerance levels and the relevance of each component”, said Juan José Herrero Villamor, Project Manager of Investigations at UPM.

Herrero also highlighted the importance of the data collected in “helping to correct manufacturing errors found in the chassis and the suspension system, as well as in re-evaluating our manufacturing systems to keep them within the appropriate tolerance levels.”

When it comes to achieving success in any competition, the skill, training and passion of the pilot are key, but so is the quality, accuracy and reliability of the vehicle. This is the cocktail of factors that will be subjected to the maximum demands of racing.

The single-seater from the Madrid Polytechnic University team competes at an international level in the Formula Student category, putting the ability of the engineering students and the accuracy with which they’re able to develop first-rate vehicles to the test.

The single-seater from the Madrid Polytechnic University team competes at an international level in the Formula Student category, putting the ability of the engineering students and the accuracy with which they’re able to develop first-rate vehicles to the test.Among motors of comparable performance (up to 600 cc), the perfection of the components, from production and assembly through to aerodynamics, are defining factors. “The power of all the vehicles is similar, making weight reduction is very interesting, as well as the necessity to keep the centre of gravity as low and centred as possible”, said Ramón Martínez Valdivia, Marketing Manager at UPM.

The Leica Absolute Tracker AT960 combined with the Leica Absolute Scanner LAS-20-8 allowed the vehicle to be measured in a very short period while still achieving a measurement uncertainty of less than 50 µm. The result of the scanning work was a transverse model of the vehicle that allowed the team to develop a range of applications: “They were able to perform aerodynamic calculations in addition to suspension modifications, notably improving their times in the next Formula Student race”, noted Sergio Herradura, Sales Engineer and Specialist in the Hexagon Manufacturing Intelligence Portable Product Line.

Fast measurement process

Through these measuring systems, Hexagon was able to monitor and identify imperfections in the single-seater design. “After assembly, it’s very important for us to quantify the errors that have been made. In order to do this, we rely on Hexagon technology to determine deviations and how they affect both the design and the resistance of the piece and the car's dynamics”, said David Ángel Fernández, Chief Engineer at UPM.

been made. In order to do this, we rely on Hexagon technology to determine deviations and how they affect both the design and the resistance of the piece and the car's dynamics”, said David Ángel Fernández, Chief Engineer at UPM.The use of the Leica Absolute Scanner LAS-20-8 was crucial for analysing the disparity between some elements. Using the accurate data gathered from the scanner point clouds, the UPM team were able to pay special attention to the areas that made the most difference. “Among the great advantages of the scanner is its ease of use and lightness in combination with the high performance it achieves. It‘s allowed us to improve our manufacturing process while taking into account tolerance levels and the relevance of each component”, said Juan José Herrero Villamor, Project Manager of Investigations at UPM.

Herrero also highlighted the importance of the data collected in “helping to correct manufacturing errors found in the chassis and the suspension system, as well as in re-evaluating our manufacturing systems to keep them within the appropriate tolerance levels.”