Hexagon enhances the quality control process during the production of hip prostheses

Dedienne Santé transformed its hip prosthesis quality control to slash inspection times and set new precision benchmarks in medical device manufacturing

Hexagon CMMs and PC-DMIS for an improved hip prosthesis manufacturing process

Dedienne Santé, a French medical device manufacturer specialising in hip prostheses, boosted its quality control process by deploying three advanced CMMs with precise measurement technologies. The company significantly improved measurement accuracy and reduced inspection times by 20%. These technological enhancements not only streamlined their production workflow but also reinforced their capacity to maintain the highest manufacturing standards in their high-tech French facility.

Founded in 1986 and based in Mauguio in the Hérault region of France, Dedienne Santé is an SME with around 60 employees. The company specialises in surgical products, including orthopaedic prostheses – in particular dual-mobility hip replacements.

Dedienne Santé has to comply with the precision requirements of the medical sector and has greatly improved the quality control process for its hip prostheses by deploying three Hexagon coordinate measuring machines (CMMs). All while limiting its carbon footprint, a crucial parameter for a company with the Coq Vert label. Among the many benefits observed, are improved measurement accuracy and a 20% time saving for operators.

The challenge

The challengeIn order to more efficiently ensure conformity at each stage of production, Dedienne Santé wanted to automate the dimensional measurement process for the crucial parts of a hip prosthesis: the cup (half-sphere part), liner, femoral head and stem. After production, conformity must again be checked and recorded during the final inspection.

This prosthesis, like any surgical product, must comply with very strict dimensions, which requires extreme precision. Manual execution of these measurement routines requires a great deal of time and effort. Dedienne Santé called Hexagon to help them measure these parts reliably, accurately and quickly.

Hexagon solutions

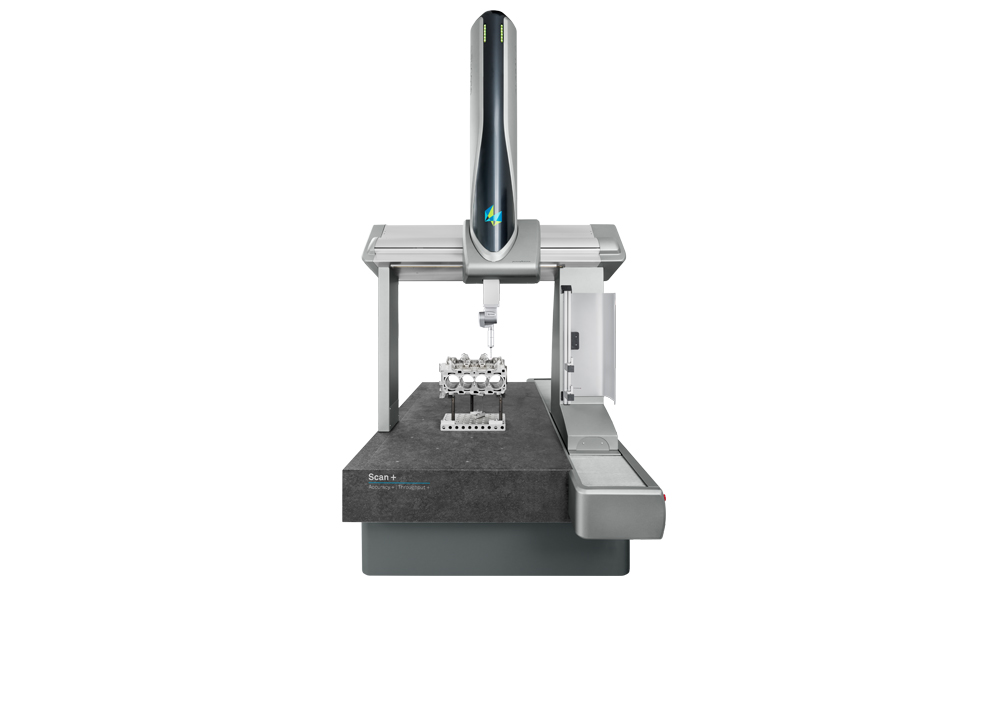

To meet this challenge, Dedienne Santé equipped itself with one latest-generation GLOBAL Scan+ CMM and two retrofitted CMMs. These systems include highly accurate HP-S-X1 scanning probes in combination with rotating probe heads for the ideal measurement of roundness and sphericity, along with easy-to-use PC-DMIS metrology software. They also include an energy-saving feature called Eco Mode that automatically switches them off when they are at a standstill. Operators were trained by Hexagon to ensure they are up to speed and in addition, Dedienne Santé has benefited from personalised support at all times.

We chose Hexagon CMMs in particular for their ability to take dimensions or circularities down to a hundredth.

Alexis Lecomte

Quality Control Manager

Dedienne Santé

Thanks to the ease-of-use of the CMMs and the simplicity of the software, with visual and automated execution methods, the operator can control the conformity of the parts in just a few clicks.

“We chose Hexagon CMMs in particular for their ability to take dimensions or circularities down to a hundredth. We also opted for a sensor with a scanning function, which is essential for checking our prostheses, where we need to achieve very high accuracies,” says Alexis Lecomte, Quality Control Manager, Dedienne Santé.

“We chose Hexagon CMMs in particular for their ability to take dimensions or circularities down to a hundredth. We also opted for a sensor with a scanning function, which is essential for checking our prostheses, where we need to achieve very high accuracies,” says Alexis Lecomte, Quality Control Manager, Dedienne Santé.

Benefits for Dedienne Santé

Hexagon has met Dedienne Santé’s expectations with the solutions it has deployed. Firstly, the very high level of precision achieved corresponds perfectly to the requirements demanded in the medical field. Secondly, the company has benefited from the user-friendliness of Hexagon’s PC-DMIS software, both for self-checking by operators in the mill-turn workshop, and for automated in-process inspection and final control.

Thirdly, thanks to this automated solution, Dedienne Santé has achieved significant productivity gains: “Hexagon’s solutions have allowed us to boost our productivity. For example, for a hip replacement cup, the time saved is about 20%. It also allows us to control our implants as a background task without supervision,” says Lecomte.

They can allocate the time saved to other tasks with higher added value. For example, operators can now run the inspection programme and return to the workshop to machine the parts.

Dedienne Santé is completely satisfied with the measurement and inspection equipment and services offered by Hexagon; they appreciate the accuracy and speed of the product, the simplicity and user-friendliness of the software, and the efficiency of the support hotline. They are counting on Hexagon to help them maintain high-tech manufacturing in their French plant and effectively adapt to meet evolving production requirements.

Dedienne Santé is completely satisfied with the measurement and inspection equipment and services offered by Hexagon; they appreciate the accuracy and speed of the product, the simplicity and user-friendliness of the software, and the efficiency of the support hotline. They are counting on Hexagon to help them maintain high-tech manufacturing in their French plant and effectively adapt to meet evolving production requirements.

“It’s important for us to select suppliers and partners who can help us maintain such a plant and high-tech manufacturing in France, in Mauguio in the Hérault region. In this respect, Hexagon is a very important partner, as it’s helping us to keep this fast, productive manufacturing capacity right here,” says Ludovic Toledo, CEO, Dedienne Santé.

Dedienne Santé has been awarded a number of labels. The company was one of the very first to be awarded the French Tech label in 2016 and 2017. It has also been awarded the Coq vert label, recognising the company’s commitment to sustainable development, in particular the reduction of greenhouse gas emissions at all stages of manufacturing. Hexagon is committed to helping the company maintain and extend this proud heritage and continue to meet all future challenges.

“We chose Hexagon CMMs in particular for their ability to take dimensions or circularities down to a hundredth. We also opted for a sensor with a scanning function, which is essential for checking our prostheses, where we need to achieve very high accuracies,” says Alexis Lecomte, Quality Control Manager, Dedienne Santé.

“We chose Hexagon CMMs in particular for their ability to take dimensions or circularities down to a hundredth. We also opted for a sensor with a scanning function, which is essential for checking our prostheses, where we need to achieve very high accuracies,” says Alexis Lecomte, Quality Control Manager, Dedienne Santé.Benefits for Dedienne Santé

Hexagon has met Dedienne Santé’s expectations with the solutions it has deployed. Firstly, the very high level of precision achieved corresponds perfectly to the requirements demanded in the medical field. Secondly, the company has benefited from the user-friendliness of Hexagon’s PC-DMIS software, both for self-checking by operators in the mill-turn workshop, and for automated in-process inspection and final control.

Thirdly, thanks to this automated solution, Dedienne Santé has achieved significant productivity gains: “Hexagon’s solutions have allowed us to boost our productivity. For example, for a hip replacement cup, the time saved is about 20%. It also allows us to control our implants as a background task without supervision,” says Lecomte.

They can allocate the time saved to other tasks with higher added value. For example, operators can now run the inspection programme and return to the workshop to machine the parts.

Dedienne Santé is completely satisfied with the measurement and inspection equipment and services offered by Hexagon; they appreciate the accuracy and speed of the product, the simplicity and user-friendliness of the software, and the efficiency of the support hotline. They are counting on Hexagon to help them maintain high-tech manufacturing in their French plant and effectively adapt to meet evolving production requirements.

Dedienne Santé is completely satisfied with the measurement and inspection equipment and services offered by Hexagon; they appreciate the accuracy and speed of the product, the simplicity and user-friendliness of the software, and the efficiency of the support hotline. They are counting on Hexagon to help them maintain high-tech manufacturing in their French plant and effectively adapt to meet evolving production requirements.“It’s important for us to select suppliers and partners who can help us maintain such a plant and high-tech manufacturing in France, in Mauguio in the Hérault region. In this respect, Hexagon is a very important partner, as it’s helping us to keep this fast, productive manufacturing capacity right here,” says Ludovic Toledo, CEO, Dedienne Santé.

Dedienne Santé has been awarded a number of labels. The company was one of the very first to be awarded the French Tech label in 2016 and 2017. It has also been awarded the Coq vert label, recognising the company’s commitment to sustainable development, in particular the reduction of greenhouse gas emissions at all stages of manufacturing. Hexagon is committed to helping the company maintain and extend this proud heritage and continue to meet all future challenges.