Fuel cell know-how in Austria sets new standards

The family business YOUR-TOOL is expanding its business areas and investing in renewable energies with manpower, production halls and a high-end machine park

Contact us

High-accuracy in family manufacturing with Hexagon CMMs

Environmental consciousness, sustainable action and consideration for their employees are part of the philosophy of the family business YOUR-TOOL GmbH, based in Freundorf, Austria, and founded in 2006. With origins as a specialist in the field of micro-punching, manufacturing tools for the ceramic PCB industry, the company quickly discovered the potential to work intensively on solutions for the eMobility business sector. Know-how and passion combined with high-precision manufacturing and measuring machines has since made YOUR-TOOL GmbH a sought-after supplier of embossing tools for fuel cell bipolar plates.

Environmental consciousness, sustainable action and consideration for their employees are part of the philosophy of the family business YOUR-TOOL GmbH, based in Freundorf, Austria, and founded in 2006. With origins as a specialist in the field of micro-punching, manufacturing tools for the ceramic PCB industry, the company quickly discovered the potential to work intensively on solutions for the eMobility business sector. Know-how and passion combined with high-precision manufacturing and measuring machines has since made YOUR-TOOL GmbH a sought-after supplier of embossing tools for fuel cell bipolar plates.The business is now dedicated to the production of high-precision embossing and punching tools. In 2021, the company invested in a new production hall in Freundorf, along with a selection of high-end machinery with which to fill it. High-precision manufacturing and measuring machines guarantee the production of tools that are leaders in the field of micro-punching. Together with their customer- and solution-oriented approach and their precision thinking, this stable of top-class milling, calibrating and measuring machines is what sets the company apart from the competition.

This includes patented technologies such as 3-5-axis micro-gloss milling, ceramic carbide milling, micro-eroding and cylindrical grinding, all of which enable unmatched high-precision tool production.

This includes patented technologies such as 3-5-axis micro-gloss milling, ceramic carbide milling, micro-eroding and cylindrical grinding, all of which enable unmatched high-precision tool production.YOUR-TOOL’s philosophy includes being technically flexible in responding to customer requests and delivering solutions on time. Furthermore, the company supports its customers at every step of the process, from development and design to production and commissioning. Their highly qualified team relies on decades of know-how, as well as on their technical equipment, and constantly educates themselves through systematic training in order to keep development processes and production techniques up to date.

Investment in progress

Since its founding, the company’s range of products has continued to expand since its early focus on the construction of punching tools. Punches were used to punch holes with a diameter of 60 microns in ceramic foils. In 2009, the company began integrating micro wire and sinker EDM for fine wires, with wire diameters from 20 to 200 microns.For die-sinking EDM, the electrode size starts from a diameter of 25 microns. With such small sizes come fine tolerances, putting the focus always on micro-precision.

With the establishment of a second location in Sankt Andrä in 2017, polishing milling became part of the team’s area of expertise. With this technology, it was possible to integrate the smallest radiuses and mirror surfaces, with surfaces as small as 20 nanometres, especially for the headlight industry and in mould making. At the same time, YOUR-TOOL also entered the market with 5-axis simultaneous milling, which enabled high-precision ranges for larger components up to 800 millimetres in diameter and 1000 millimetres in height. Thus, machine accuracies of 5 microns were achieved on 5 axes simultaneously.

A new business field – bipolar plates for fuel cells

The work grew even more precise in 2018 with entry into the supplier market for hydrogen fuel cells. With the aim of becoming the market leader for embossing tools for the production of bipolar plates, YOUR-TOOL invested in an ultra-precise milling machine in 2018. Its smallest milling cutter – used for hardened steel – has a diameter of only 70 microns. Hydrogen fuel cells represent an environmentally friendly future technology and alternative to fossil combustion engines. Work in this area was completely in line with YOUR-TOOL’s values, at the centre of which is environmental awareness.

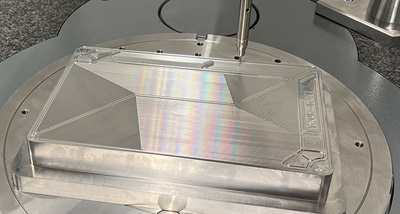

Hydrogen fuel cells represent an environmentally friendly future technology and alternative to fossil combustion engines. Work in this area was completely in line with YOUR-TOOL’s values, at the centre of which is environmental awareness.The cells consist of a large number of bipolar plates stacked on top of each other, which form the heart of a fuel cell. The plates are produced through an embossing process that provides them with fine grooves. The precise stacking of the plates creates channels, through which the hydrogen-oxygen mixture can flow. To avoid cumulative defects in the stacked bipolar plates, a highly accurate as well as durable embossing tool is essential.

“By manufacturing our embossing and punching tools on high-precision milling machines and applying constant quality control, we achieve tools with a very long service life and therefore impressive durability,” says Andreas Zöttl, Managing Director at YOUR-TOOL. “We’re very proud of this.”

The importance of the use of fuel cells in the eMobility industry is increasing. Currently still primarily used in trucks and buses, the first vans with hydrogen as an energy source are beginning to push into the private customer business.

“In order to be able to generate as much energy as possible in the smallest possible space, the surface through which the hydrogen mixture flows must be enlarged,” explains Zöttl. “Our know-how, coupled with our unique machinery, enables us to emboss ever narrower channels, and at the same time ever smaller corner radiuses on the bipolar plates. Following our current success, our goal is now to become even more intensively involved with the fuel cell topic.”

The need for high-precision embossing tools for eMobility customers was an additional reason for investing in another milling machine in 2018. Three years later, the new production hall in Freundorf now produces series parts for fuel cells, stamping tools for eMobility batteries and mirror surface milling tools for the optical industry. In addition to innovative tools for the production of fuel cell components, YOUR-TOOL is also working on projects for the use of batteries in the field of photovoltaic systems.

The need for high-precision embossing tools for eMobility customers was an additional reason for investing in another milling machine in 2018. Three years later, the new production hall in Freundorf now produces series parts for fuel cells, stamping tools for eMobility batteries and mirror surface milling tools for the optical industry. In addition to innovative tools for the production of fuel cell components, YOUR-TOOL is also working on projects for the use of batteries in the field of photovoltaic systems.YOUR-TOOL is not only active in the field of eMobility, but also in medical technology, the electronics industry and in gearbox construction for the aerospace industry. This includes customers all over the world, with the business’ export share at an extremely high 90 percent. What the various industries YOUR-TOOL serves have in common is that the highest levels of precision are always key.

Quality inspection and measuring systems on the test bench

The complexity of the embossing tools produced by YOUR-TOOL has led to the need for sophisticated measuring equipment that is capable of measuring such fine-tolerance tools.In its early years, YOUR-TOOL still measured with standard measuring equipment and gauges. With the construction of the new company building in 2021, YOUR-TOOL decided to invest in advanced coordinate measuring machines (CMMs).

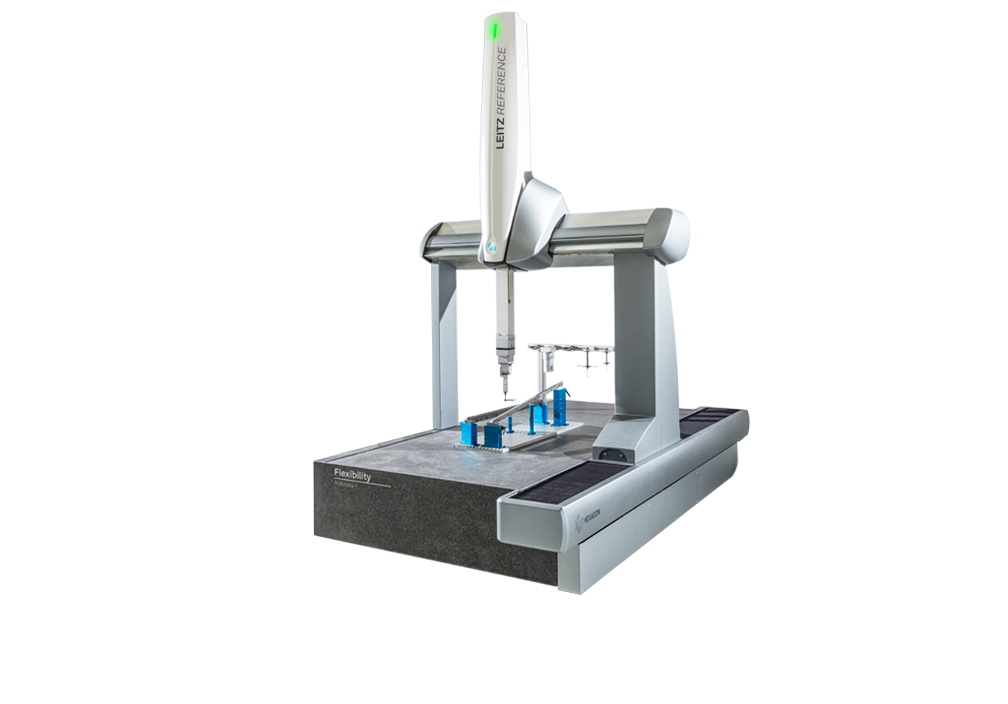

“We were quickly convinced by a colleague that Hexagon was the right supplier to offer the best in this high-precision market,” says Zöttl. Today, YOUR-TOOL’s customised metrology lab features an OPTIV M multisensor system, a Leitz Reference ultra-high-precision CMM (mainly used for larger components) and a Leitz Infinity CMM.

“We’re known for producing to 2 microns, so you have to be able to measure into that range,” says Zöttl. “Customers expect a quality report from every component we produce, so we needed measurement technology we could rely on even at incredibly fine tolerances.”

Leitz Infinity – the most accurate CMM in its class

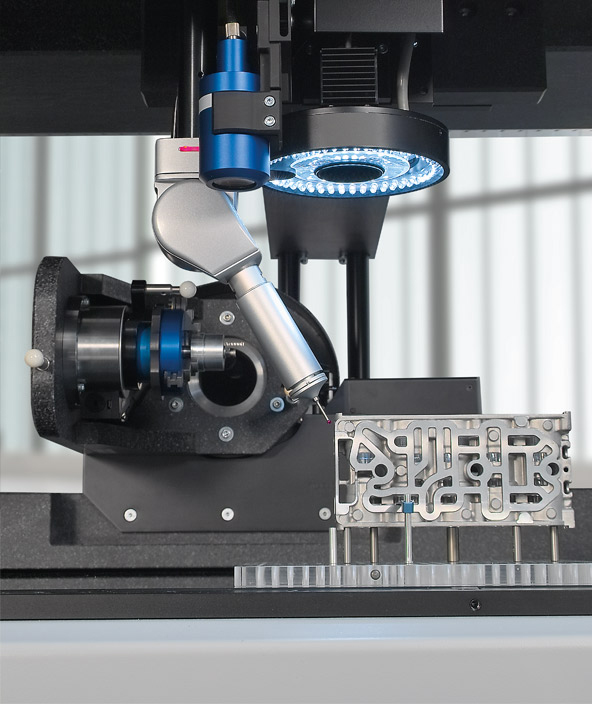

The Leitz Infinity is the most accurate 3D CMM in its class and enables the combination of optical and tactile sensors within a single highly accurate measuring system.

Every detail of the Leitz Infinity is designed to reliably and precisely perform ultra-high-accuracy measurements. Characteristic of the Leitz Infinity is its closed-frame design, which includes a solid granite base bed as well as a fixed gantry with cast stands and a granite crosshead.

The quality assurance area represents a separate department at YOUR-TOOL, and every part that leaves the production site is measured and therefore guaranteed to deliver 100% quality. Smaller components are inspected on the OPTIV M multisensor system, larger ones on the Leitz Reference and Leitz Infinity. The Leitz CMMs probe each of the high-gloss parts being produced tactilely with a ball diameter of 0.2 millimetres.

The quality assurance area represents a separate department at YOUR-TOOL, and every part that leaves the production site is measured and therefore guaranteed to deliver 100% quality. Smaller components are inspected on the OPTIV M multisensor system, larger ones on the Leitz Reference and Leitz Infinity. The Leitz CMMs probe each of the high-gloss parts being produced tactilely with a ball diameter of 0.2 millimetres.

“YOUR-TOOL’s machinery, whether milling or measuring machines, is unique in Austria,” adds Hexagon CO Manager, Thomas Szirtes. “No other company works to such high precision, probably Europe-wide.”

“With Hexagon’s hardware and software solutions, we see ourselves very well equipped for the future”, says Zöttl.

“We’re glad to have found a provider of comprehensive measurement solutions in Hexagon, where quality is just as important as it is to us and where we can work together according to the customer- and solution-oriented approach that we consider so valuable.”