From automation to monitoring: adapting technologies for more efficiency is the future of agribusiness

Machine automation technologies are increasingly present in the daily lives of farmers and rural managers. In a survey conducted by the Federation of Agriculture and Livestock of Mato Grosso do Sul, Brazil (Famasul), for example, 65.6% of respondents reported that they use precision agriculture software in their productions. However, experts in the field indicate that there is still much to advance to an integrated and digital field — there are gaps, especially when it comes to monitoring operations.

"In recent years, we have experienced a great popularisation of solutions aimed at automation, mainly due to the expansion of knowledge of the benefits that they can bring. Because of this, we have several agricultural machines working with embedded displays, performing functions related to precision agriculture," points out Bernardo de Castro, president of Hexagon's Agriculture division — a company that develops and provides digital agricultural and forestry solutions. As demonstrated by the same study by FAMASUL, it is possible to have an increase of up to 29% in productivity and an average reduction of 23% in expenses with inputs with the use of this type of technology.

However, Bernardo points out that this digitalisation is generating extremely relevant data that is still little used. "We see today that there is an opportunity in the market to expand technologies from already installed bases of displays and sensors. We are investing more and more in this idea of leveraging tools that make automation, increasing technologies that are already used in the field to monitor operations," explains the president of Hexagon's Agriculture division.

The idea of encouraging more intensive use of data being generated by equipment in the field is a trend that is expected to grow in the coming years. In the study "Digital Agriculture in Brazil" conducted by the Brazilian Agricultural Research Company (Embrapa) in 2020, most of the farmers and agricultural companies interviewed stressed the increasing need for the use of digital technologies to, mainly, obtain information and plan the activities of the property (67.1%) and the management of the rural area (59.7%).

It is already possible to use the same devices that perform precision agriculture functions — such as advanced operations control, application of inputs and auto steering, for example — for fleet monitoring. Thus, managers have a view of what is happening and a guarantee that the maximum performance of each machine is being performed.

Check out three solutions that help in agricultural and forestry monitoring:Machine Monitoring

With the help of automation by workflow, HxGN AgrOn Machine Monitoring manages information on the machines and fleets in the field, recording from second to second the position and the activity being performed in the cultivation and harvesting.

This monitoring can also be integrated with pre-existing sensors on the machine and allows the setting of alarms for certain situations. Reports on yield, productivity, distance, speed, among other points, are generated for analysis.

Control Room

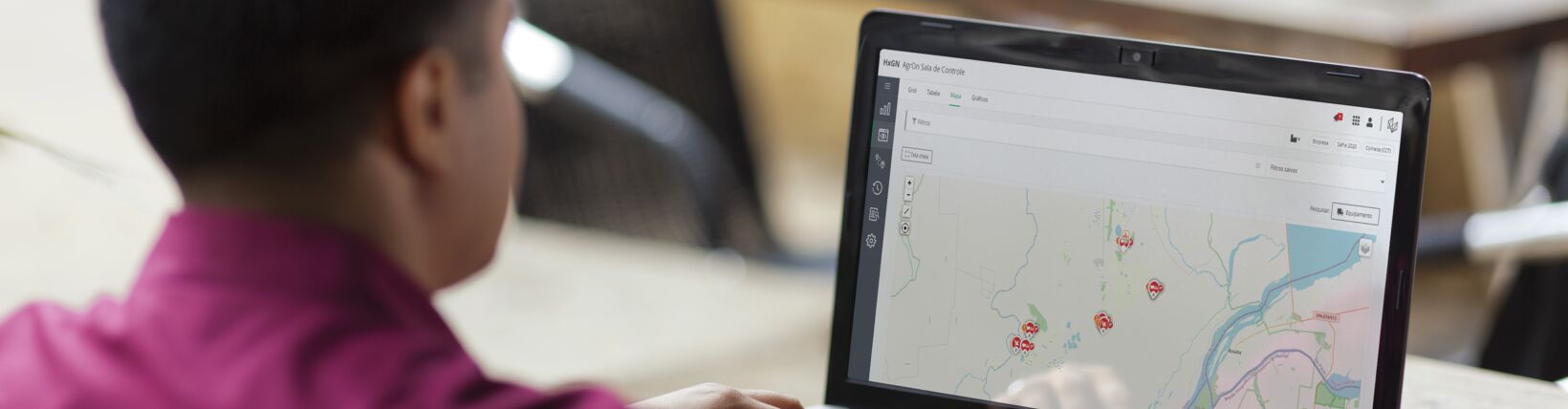

There are technologies that allow all monitoring in the field to take place at a distance. An example is HxGN AgrOn Control Room, software that allows real-time monitoring of everything that happens during farming directly from a remote command centre.

The solution works based on the transfer of information from the on-board computers of the agricultural machinery to the control room cloud through 3G, 4G, Wi-Fi or satellite communication channels. As such, managers can make decisions and perform rapid interventions whenever necessary, even when away from production.

Raw Material Traceability

In addition to the field, it is also possible to monitor the entire path taken by the raw material, from its origin to delivery to the industry. HxGN AgrOn Raw Material Traceability, for example, is a solution installed in harvesters, haul-outs and trailers to carry out sugarcane screening.

"In addition to the exact location of all of the production, this type of technology collects information such as the area and the duration of the harvest, increasing the quality and agility of operations and overcoming the lack of infrastructure for tracking loads in the field", reinforces Bernardo de Castro. Human intervention is also reduced, dispensing with manual notes and identification labels of the raw material during the journey.