The early roots of human technology

Evaluating ancient stone tools in 3D

Contact us

When our earliest ancestors began breaking stone pebbles to create sharp cutting edges, our cultural development became inexorably linked with tool use. Over the next 2.5 million years, humans continued to manipulate technological strategies to meet diverse environmental, social, and economic challenges.

In Africa, highly mobile cattle herding developed in the Sahara by 8,000 years ago. By 3,000 BC stone-tool-using herders had migrated into southern Kenya. They left abundant evidence of their technologies in the form of stone tools and tool production debris. Until recently, there has been only a few exploratory attempts to use the stone tool data sets to answer anthropological research questions about early African herders. As a part of a Ph.D. research, a large sample of stone tools from archaeological sites across southern Kenya is scanned to 3D analyse how trade and exchange networks were formed among these cattle herders.

Objective and measuring object

In order to study stone tools, it is important to assess how people reduced lithic “cores”; the nodules of stone that are prepared through flaking for the controlled removal of blades. The shape and size of cores and blades is not random, but depends on the experience of the person and the technological systems available to him or her. Stone tool morphologies reflect entire life histories, from the moment the stone is quarried, through production and use, up to final discard. Archaeologists strive to reconstruct these important elements of prehistoric lifeways through studying stone tool form, but depend on the precision and accuracy of measurements.

In the past, research has been problematic because stone artefacts are complex three-dimensional objects. Metrics like length, width, and thickness are different across an individual piece, and caliper measurements can only reflect a single point. Many shape aspects cannot be directly measured. Methods that use proxies to estimate curvature and twist of lithic tools or debris have been found to be unreliable, with high degrees of interobserver errors. A lack of transparency around where different analysts take even basic measurements continues to cause problems in developing and applying repeatable methods. This is most problematic for features that cannot be easily measured, which different archaeologists recognize, classify, and record in different ways.

In the past, research has been problematic because stone artefacts are complex three-dimensional objects. Metrics like length, width, and thickness are different across an individual piece, and caliper measurements can only reflect a single point. Many shape aspects cannot be directly measured. Methods that use proxies to estimate curvature and twist of lithic tools or debris have been found to be unreliable, with high degrees of interobserver errors. A lack of transparency around where different analysts take even basic measurements continues to cause problems in developing and applying repeatable methods. This is most problematic for features that cannot be easily measured, which different archaeologists recognize, classify, and record in different ways.

Measuring system and setup

The use of 3D scanning and modelling technologies offer the most promising direction for improving the ways to measure and describe stone tools. Archaeologists have already begun using 3D scanning devices for digitally curating pottery, animal bones, and documenting in-situ excavations. Quantitative analysis of 3D models is still in its infancy; only a handful of studies have attempted to use measurements of stone tools to answer anthropological questions. However, the results of digitally analysing high-definition models have so far been extremely positive.

For the 3D capture of the stone tools, the AICON SmartScan with 60 mm and 125 mm fields of view and a camera resolution of 5 megapixels is used, combined with a manual turntable. This white light scanner setup is especially well suited to capture artefacts with a size from 20 cm to less than 5 cm in length with all their details.

Workflow

Most of the scanned tools are made of obsidian, a very shiny black volcanic glass. Analysts using laser scanners have reported that data collection on obsidian surfaces is very poor, even with various surface treatments. The AICON SmartScan’s very long white light exposure captures a large amount of data from an untreated obsidian surface. A thin layer of whitening powder applied to the surface of an obsidian edge is enough to drastically reduce exposure times, and increases the total data collected. In the field in Kenia, baby-powder was used to replace the powder typically used for professional scanning. The most problematic areas are the sharp edges of obsidian blades, which can be only a few nanometres thick and sharper than surgical steel. The scanner captures most or all edges for roughly 40 % of the tools. More importantly, the software AICON OptoCat can properly align the faces of obsidian tools, even when the edge is too thin and transparent to be fully collected. The full edges are not required for any 3D measurements, but hole-fill features in OptoCat can easily add them for visualisation and display purposes.

Result

In total, 366 archaeological specimens from 12 archaeological sites were scanned, covering an area from the Great Rift Valley to Lake Victoria. The scanning rate was extremely rapid, especially when compared to rates reported for other scanners. The high efficiency of the AICON SmartScan allowed to collect what is now the largest digitised archaeological assemblage for Africa, and one of the largest 3D stone tool data sets in the world.

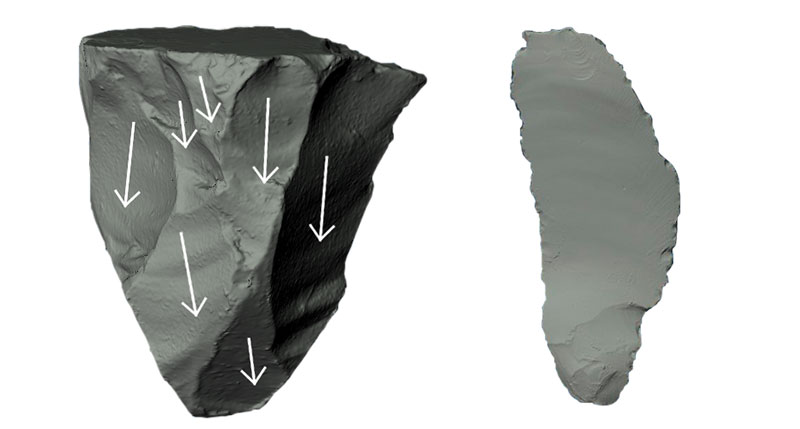

The rapid collection of data does not come at the cost of data quality. The 3D models are extremely detailed and include important technical features like the “ripples” produced during flake production that reflect directionality. Edge wear, utilisation, and damage are also visible, even when very small. The jagged edges caused by step fractures, a result of repeated strikes to an unprepared platform are beautifully represented in the 3D images. These are typically associated with low-skilled production, and the high rate of these recorded at the Elmenteitan Quarry Site may indicate people using the site were learning how to make tools. It is difficult to draw or describe the intensity of step fractures, but they can be easily displayed with the 3D data. The quality of the scans is so high that one can even determine the quality of the raw material: High quality obsidian has smooth surfaces, while lower quality obsidians can be rough and porous. These surface textures are preserved in the 3D data.

The PLY files produced by OptoCat can be imported into a suite of morphometric analysis programs to measure complex dimensions like curvature and twist, convexity, surface area features, and depth of different fracture types on tools. This provides a new and innovative approach for using lithic debris, the most common form of archaeological material in most parts of the world, to model whole reduction sequences. Using statistical analysis, the 3D metrology is showing which sites are connected through the exchange of stone tools, and which communities share reduction techniques and might be socially related. These are new approaches in lithic analysis, only made possible through the application of high precision 3D scanning and modelling.

Beyond the analytical projects, the 3D models provide exciting opportunities for data visualisation, data sharing, and teaching. The dark shiny surfaces of obsidian tools make them very difficult to photograph. OptoCat allows for the adjustment of lighting on the models, such that exported screen captures of the 3D models display the artefact’s surface much more clearly. Thus, high-quality images of either whole tools, or zoomed close-ups of small features that would otherwise require a microscope can be published. 3D models can be displayed as 3D objects in public talks and conference presentations, making it much easier to demonstrate complex technological attributes. On a very practical level, these models are also just much nicer to look at during presentations, and help attract attention.

In addition, archaeological sciences are increasingly placing value on data sharing and open access. The 3D models created on the data captured with the AICON SmartScan serve as data basis to be shared with scholars all over the world. Researchers will no longer have to visit multiple museums or re-measure the same assemblages over and over, but can access 3D collections like this one to conduct new analyses.

AICON 3D Systems honoured this exceptional 3D scanning project with the Bernd Breuckmann Award 2013.