ALPHACAM Waveform halves automation component roughing cycles

Allied Automation - Ireland

Contact us

Allied Automation was established in Dublin in 1998. The main aspect of the company’s business is manufacturing bespoke, automated assembly machines used by many of the world’s leading medical, pharmaceutical, and life science companies. Allied Automation has its own modern high precision workshop and they say that pushing Alphacam’s Waveform strategy to the limit has reduced rough machining cycles by half.

Based at Finglas, close to Dublin International Airport, Allied Automation say their customers usually come to them with a project, and ask them to commission a machine to be built to automate part, or all of the production process. Since its foundation, the company has delivered over 2500 precision engineering projects to clients in Ireland, the UK, mainland Europe, USA and the Middle East.

Production Manager Owen Donnelly says they have recently completed a 15 month-long project for an assembly and test machine for feeding various sizes of catheters, coiling them on multiple mandrels, stripping them and loading them into sterile pouches, and sealing them at a rate of 30 PPM.

Another example is a high precision robotic process for grinding radii on blade edges. These blades are used by Orthopaedic Surgeons for cutting bone during surgical procedures. A robot picks the blade from a precision in-feed fixture, presents it to a grinding wheel, precisely manipulating it to create the precision radii on four edges. It then places it back on a precision outfeed carrier.

Another example is a high precision robotic process for grinding radii on blade edges. These blades are used by Orthopaedic Surgeons for cutting bone during surgical procedures. A robot picks the blade from a precision in-feed fixture, presents it to a grinding wheel, precisely manipulating it to create the precision radii on four edges. It then places it back on a precision outfeed carrier.

Each of Allied Automation’s machines can contain up to 5,000 components, and vary in size from small bench top assembly aids to 6 metre x 2.5 metre standalone machines.

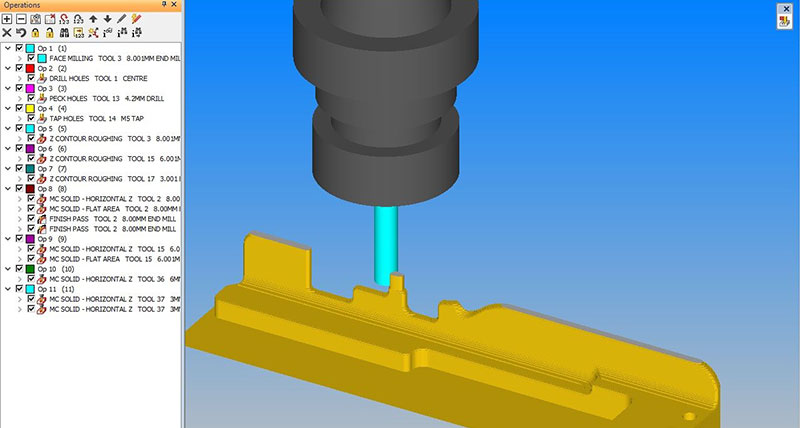

“We complete everything in-house: design, development, production, electrical, pneumatics process control, vision inspection, and robotics. All the high-precision parts are produced in our tool room on CNC milling machines and lathes controlled by Alphacam.

“Our biggest challenge was getting the components manufactured in the most efficient way” Since introducing Alphacam this has really increased the speed of toolpath creation.”

Owen Donnelly says the biggest revolution was the introduction of Alphacam’s Waveform Roughing technique, significantly reducing the overall machining time.

A point echoed by Toolmaker Daniel Monaghan. “Originally we feared that ramping up the feed and speed rates, as recommended by Alphacam, would damage our cutting tools, so we ran the cycle slowly at first. As soon as we realised how efficiently it worked our confidence grew and we pushed it to the limit. This is how we work our machines now and it reduces up to half the time on a rough machining cycle.”

He says it also prolongs tool life. “Machining the conventional way, the cutters would last two months. But with waveform machining, and by utilising the full cutter flute length, rather than just the bottom end of the tool, they don’t need replacing for six months, and the finishing cutters are lasting eight months. It’s saving us a lot of money on cutting tools.”

He adds that a step-by-step procedure of using Alphacam begins when he imports a drawing from SolidWorks and decides on the type of tooling required. “I extract the solid model and check the radii to see what size cutters are required, including any ball nose cutters for 3D milling, then I check what roughing cycles are required for pockets and holes, and any 3D work.”

Once that is completed the program is created and a simulation is run. The required material is prepared – usually aluminium, stainless steel, ertalyte polymer, or acetal. After setting up the material on the machine, a list of tools is created. The final programme is then run to machine the required product.

He says Alphacam makes his job much easier, reducing time, stress, and errors. “For example, if we were selecting a number of holes before, we would really have to focus on the various sizes resulting in potential errors. Now Alphacam groups them together, saving time and eliminating the risk of errors.”

Alphacam recently-introduced ribbon-style bar and fully customisable quick access radial interface, this originally took Daniel Monaghan and his colleagues well out of their comfort zone. “But once we got used to these new functions and realised the benefits, it has made our work easier and much more efficient.”

Based at Finglas, close to Dublin International Airport, Allied Automation say their customers usually come to them with a project, and ask them to commission a machine to be built to automate part, or all of the production process. Since its foundation, the company has delivered over 2500 precision engineering projects to clients in Ireland, the UK, mainland Europe, USA and the Middle East.

Production Manager Owen Donnelly says they have recently completed a 15 month-long project for an assembly and test machine for feeding various sizes of catheters, coiling them on multiple mandrels, stripping them and loading them into sterile pouches, and sealing them at a rate of 30 PPM.

Another example is a high precision robotic process for grinding radii on blade edges. These blades are used by Orthopaedic Surgeons for cutting bone during surgical procedures. A robot picks the blade from a precision in-feed fixture, presents it to a grinding wheel, precisely manipulating it to create the precision radii on four edges. It then places it back on a precision outfeed carrier.

Another example is a high precision robotic process for grinding radii on blade edges. These blades are used by Orthopaedic Surgeons for cutting bone during surgical procedures. A robot picks the blade from a precision in-feed fixture, presents it to a grinding wheel, precisely manipulating it to create the precision radii on four edges. It then places it back on a precision outfeed carrier. Each of Allied Automation’s machines can contain up to 5,000 components, and vary in size from small bench top assembly aids to 6 metre x 2.5 metre standalone machines.

“We complete everything in-house: design, development, production, electrical, pneumatics process control, vision inspection, and robotics. All the high-precision parts are produced in our tool room on CNC milling machines and lathes controlled by Alphacam.

“Our biggest challenge was getting the components manufactured in the most efficient way” Since introducing Alphacam this has really increased the speed of toolpath creation.”

Owen Donnelly says the biggest revolution was the introduction of Alphacam’s Waveform Roughing technique, significantly reducing the overall machining time.

A point echoed by Toolmaker Daniel Monaghan. “Originally we feared that ramping up the feed and speed rates, as recommended by Alphacam, would damage our cutting tools, so we ran the cycle slowly at first. As soon as we realised how efficiently it worked our confidence grew and we pushed it to the limit. This is how we work our machines now and it reduces up to half the time on a rough machining cycle.”

He says it also prolongs tool life. “Machining the conventional way, the cutters would last two months. But with waveform machining, and by utilising the full cutter flute length, rather than just the bottom end of the tool, they don’t need replacing for six months, and the finishing cutters are lasting eight months. It’s saving us a lot of money on cutting tools.”

He adds that a step-by-step procedure of using Alphacam begins when he imports a drawing from SolidWorks and decides on the type of tooling required. “I extract the solid model and check the radii to see what size cutters are required, including any ball nose cutters for 3D milling, then I check what roughing cycles are required for pockets and holes, and any 3D work.”

Once that is completed the program is created and a simulation is run. The required material is prepared – usually aluminium, stainless steel, ertalyte polymer, or acetal. After setting up the material on the machine, a list of tools is created. The final programme is then run to machine the required product.

He says Alphacam makes his job much easier, reducing time, stress, and errors. “For example, if we were selecting a number of holes before, we would really have to focus on the various sizes resulting in potential errors. Now Alphacam groups them together, saving time and eliminating the risk of errors.”

Alphacam recently-introduced ribbon-style bar and fully customisable quick access radial interface, this originally took Daniel Monaghan and his colleagues well out of their comfort zone. “But once we got used to these new functions and realised the benefits, it has made our work easier and much more efficient.”