ALPHACAM “provides the line of least resistance” for solid timber specialist, Woodbase Joiners

Woodbase Joiners - U.K.

Contact us

The combination of Alphacam’s parametric function and its ability to drive 5-axis routers is the way forward for a company focusing on high end solid timber joinery.

Woodbase Joiners specialise in bespoke doors, windows and staircases, along with skirting boards, architraves, mouldings and brackets, mainly for domestic customers and builders. The company, which operates from a 7,500 square foot factory and a 900 square foot unit on the same business park near the East Sussex coast, installed Alphacam Standard in 2016, but upgraded to the Ultimate package shortly afterwards.

Managing Director Simon Bartlett explains: “We’d always intended to upgrade once we’d got to grips with the basic package. But we unexpectedly had the chance to employ a draughtsman/programmer who has worked with Alphacam for 15 years, and when he joined us he was frustrated that the Standard module couldn’t do what he wanted. So we accelerated our investment with Ultimate.”

That someone was Stuart Betts, who Simon Bartlett says has now got their 5-axis Maka PE 70 router, with 6-metre x 1.4-metre working area, “flying like it should be,” through Alphacam Ultimate.

“My main prompt to go with Ultimate immediately, was when we needed to produce a large curved component,” Simon Bartlett says. “Although we did it on the router, without the benefit of 5-axis programming it was a long winded process.”

Alphacam is now used on many projects, and while they have a separate specialist software for general staircase work, Alphacam is becoming increasingly useful for handrails and other complex aspects of staircases. “Although we do use conventional machines for some things, since installing Ultimate we’re increasingly cutting more and more components on the router, for the time saving, precision and repeatability that it offers.”

And he says it is reassuring, both for Woodbase and their customers, that the products coming off the CNC machine tool will always be exactly as they’re drawn. “It eliminates the potential for human error, and means that if a customer wants more of a particular component in the future, we can simply run the program again.”

And he says it is reassuring, both for Woodbase and their customers, that the products coming off the CNC machine tool will always be exactly as they’re drawn. “It eliminates the potential for human error, and means that if a customer wants more of a particular component in the future, we can simply run the program again.”

He describes Alphacam as providing the line of least resistance. “People always do things the easiest way they can, so if it’s easier for us to draw a component in Alphacam and run it on the router, we will. Even if it’s a one-off which we may have previously done on the spindle moulder, we’ll now do it with Alphacam.”

That point is echoed by Stuart Betts, who says 5-axis machining and parametrically-created components are the way forward for Woodbase Joiners. One of his first tasks on arriving at the company was to set about establishing a full parametric door library in Alphacam, as well as all their hardware items such as butts, multi-point door lock components and weatherseals.

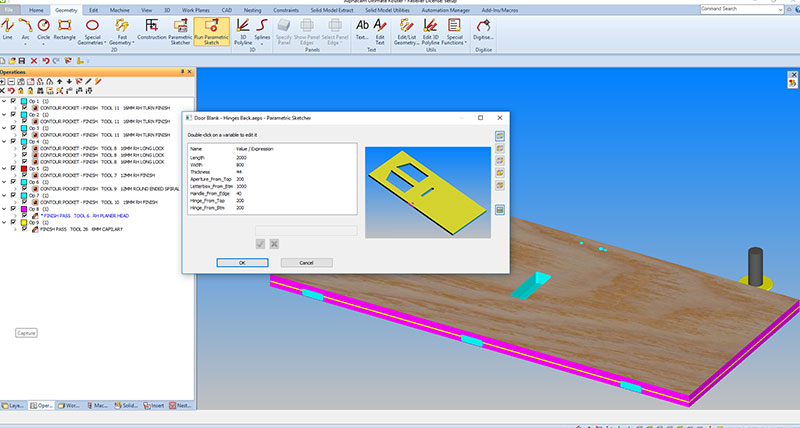

With Alphacam’s Parametric Sketcher, common CAD geometry is created automatically, regenerating the file with any required variables, meaning there is no need to redraw similar components. They are built using standard geometry commands, with different sizes being created by simply modifying the values of one or more variables. “The parametric function is an absolute godsend, as we don’t have to draw the component every time. We simply pull out a door that is similar to the one we want to create, put in the sizes and drag and drop all the ironmongery, then send it to the CNC router.”

And he is now creating door rails, door styles, box frame windows and joinery components in the parametric library. “Once we’ve created a parametric program for any joinery item it’s so quick and easy to produce new components. Everything is simply driven from a measurement.”

Appropriate parametric programs for new projects are pulled from the library, or created from scratch on the rare occasion there is nothing with a close reference to what they need. “Even Z-axis curved work is no problem – parametric programming speeds up the process and means we can produce exactly what we want with no constraints.”

He says upgrading to Alphacam Ultimate is really pushing Woodbase forward. “Standard was perfect for our 2D and 3D work, but we couldn’t do shaped or wreath handrails, for instance. Ultimate supports full 4- and 5-axis simultaneous machining for our high specification joinery. I use suction pods on the machine as well as pneumatic clamps and a laser positioning system, which Alphacam reads easily to speed up placement of workpieces.”

The final word goes to Simon Bartlett, who says they’re taking on work they would not have considered previously, because Alphacam now makes it cost effective. This includes gaining Fire Door Adjuster certification. “The increasing complexity of fire door components means it’s not simply a case of making apertures and cut-outs. It involves complicated HARDWARE as well, and to program and machine the components in any other way than on a router makes it prohibitively expensive. And we’re also looking at panel processing for fit-out cladding thanks to Alphacam.”

Woodbase Joiners specialise in bespoke doors, windows and staircases, along with skirting boards, architraves, mouldings and brackets, mainly for domestic customers and builders. The company, which operates from a 7,500 square foot factory and a 900 square foot unit on the same business park near the East Sussex coast, installed Alphacam Standard in 2016, but upgraded to the Ultimate package shortly afterwards.

Managing Director Simon Bartlett explains: “We’d always intended to upgrade once we’d got to grips with the basic package. But we unexpectedly had the chance to employ a draughtsman/programmer who has worked with Alphacam for 15 years, and when he joined us he was frustrated that the Standard module couldn’t do what he wanted. So we accelerated our investment with Ultimate.”

That someone was Stuart Betts, who Simon Bartlett says has now got their 5-axis Maka PE 70 router, with 6-metre x 1.4-metre working area, “flying like it should be,” through Alphacam Ultimate.

“My main prompt to go with Ultimate immediately, was when we needed to produce a large curved component,” Simon Bartlett says. “Although we did it on the router, without the benefit of 5-axis programming it was a long winded process.”

Alphacam is now used on many projects, and while they have a separate specialist software for general staircase work, Alphacam is becoming increasingly useful for handrails and other complex aspects of staircases. “Although we do use conventional machines for some things, since installing Ultimate we’re increasingly cutting more and more components on the router, for the time saving, precision and repeatability that it offers.”

And he says it is reassuring, both for Woodbase and their customers, that the products coming off the CNC machine tool will always be exactly as they’re drawn. “It eliminates the potential for human error, and means that if a customer wants more of a particular component in the future, we can simply run the program again.”

And he says it is reassuring, both for Woodbase and their customers, that the products coming off the CNC machine tool will always be exactly as they’re drawn. “It eliminates the potential for human error, and means that if a customer wants more of a particular component in the future, we can simply run the program again.”He describes Alphacam as providing the line of least resistance. “People always do things the easiest way they can, so if it’s easier for us to draw a component in Alphacam and run it on the router, we will. Even if it’s a one-off which we may have previously done on the spindle moulder, we’ll now do it with Alphacam.”

That point is echoed by Stuart Betts, who says 5-axis machining and parametrically-created components are the way forward for Woodbase Joiners. One of his first tasks on arriving at the company was to set about establishing a full parametric door library in Alphacam, as well as all their hardware items such as butts, multi-point door lock components and weatherseals.

With Alphacam’s Parametric Sketcher, common CAD geometry is created automatically, regenerating the file with any required variables, meaning there is no need to redraw similar components. They are built using standard geometry commands, with different sizes being created by simply modifying the values of one or more variables. “The parametric function is an absolute godsend, as we don’t have to draw the component every time. We simply pull out a door that is similar to the one we want to create, put in the sizes and drag and drop all the ironmongery, then send it to the CNC router.”

And he is now creating door rails, door styles, box frame windows and joinery components in the parametric library. “Once we’ve created a parametric program for any joinery item it’s so quick and easy to produce new components. Everything is simply driven from a measurement.”

Appropriate parametric programs for new projects are pulled from the library, or created from scratch on the rare occasion there is nothing with a close reference to what they need. “Even Z-axis curved work is no problem – parametric programming speeds up the process and means we can produce exactly what we want with no constraints.”

He says upgrading to Alphacam Ultimate is really pushing Woodbase forward. “Standard was perfect for our 2D and 3D work, but we couldn’t do shaped or wreath handrails, for instance. Ultimate supports full 4- and 5-axis simultaneous machining for our high specification joinery. I use suction pods on the machine as well as pneumatic clamps and a laser positioning system, which Alphacam reads easily to speed up placement of workpieces.”

The final word goes to Simon Bartlett, who says they’re taking on work they would not have considered previously, because Alphacam now makes it cost effective. This includes gaining Fire Door Adjuster certification. “The increasing complexity of fire door components means it’s not simply a case of making apertures and cut-outs. It involves complicated HARDWARE as well, and to program and machine the components in any other way than on a router makes it prohibitively expensive. And we’re also looking at panel processing for fit-out cladding thanks to Alphacam.”