ALPHACAM macro skates over Cambian’s complex parts

Cambrian Engineering - U.K.

Contact us

A company specialising in complex components for products such as skate parks and aircraft flight simulators, has saved hundreds of hours of programming time with a bespoke macro written for its ALPHACAM software.

Cambian Engineering Solutions focuses on using wood in the engineering world, where it’s less prevalent than metal. Working mainly within the architectural and engineering sectors, the company provides a complete solution with engineered wood.

Managing Director Piers Chapman explains: “We take the technology from the engineering sector and use that within both the architectural and engineering worlds, but predominantly with wood instead of traditional metal or composites.”

A recent example of bringing wood into an engineering application involved the cockpit for a training flight simulator. This was a high-fidelity system to be mounted on a full-motion frame, and internally was indistinguishable from a real aircraft cockpit. “For this project we replaced a composite, which had two distinct benefits: the product is more sustainable; and it’s considerably more accurate.”

A sizeable part of their business within the architectural sector is providing products for extreme and action sports facilities, such as climbing walls and skate parks. “We frequently create extremely complicated free-form wooden structures on a large scale, and these are all designed and manufactured in-house.”

A sizeable part of their business within the architectural sector is providing products for extreme and action sports facilities, such as climbing walls and skate parks. “We frequently create extremely complicated free-form wooden structures on a large scale, and these are all designed and manufactured in-house.”

He says their skate park assemblies comprise tens of thousands of individual, unique components, all modelled, machined, pre-assembled and shipped out in hundreds of separate modular elements.

“It’s critical that all our products are precision machined, whether it’s something like the cockpit where we need to achieve tight tolerances on a small scale, or in the architectural world where we’re assembling off-site, and the cumulative stack-up of any error, multiplied by extensive modular elements, becomes considerable.” He also points out there are quite large tolerances within the engineered wood panels themselves, which is dealt with through their extensive design for manufacture experience.

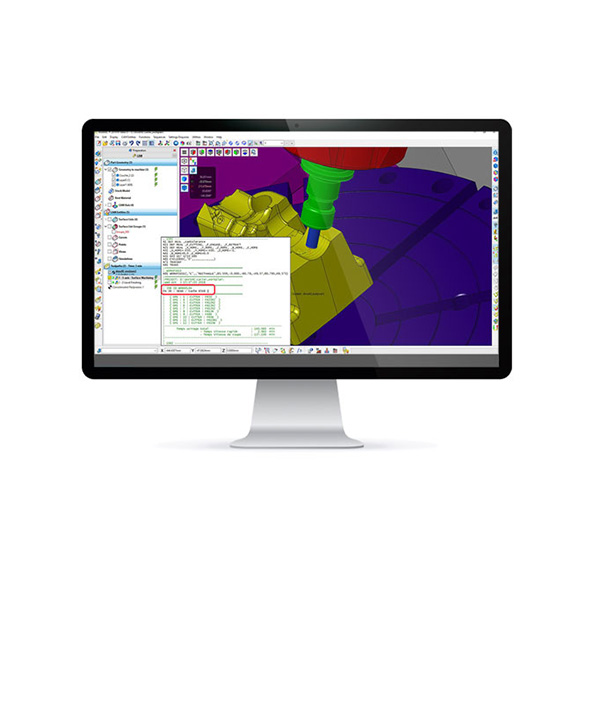

ALPHACAM is a vital bridge between their NX CAD software and the woodWOP CAM software which runs a Weeke Vantage 200 4.5-axis router and nester from the Homag Group. “Many woodworking companies work with just 2D data, but we do a lot of work via the 3D world, so ALPHACAM is the perfect tool for us.”

The company, operating with seven full-time employees from a 7,000 square foot workshop in West Sussex, uses ALPHACAM to program two fundamentally separate types of part – firstly, planar components which are nested, and secondly, those which need to be 3D machined.

“The planar components are typically 2.5D imported as solid models, and then we use ALPHACAM to extract the features. Where possible we move on to programming in a semi-automatic way using Machining Styles. For the more complex solid models we use 3D machining strategies working with the solid model or surface geometry directly.

“ALPHACAM is the conduit between our 3D design environment and the physical embodiment of the parts we’re manufacturing. Nothing could get made without it.”

However, the unusual 4.5-axis head on their machine tool, meant that programming was not straight forward, and Andrew Harfield, ALPHACAM’s Area Sales Manager, created a complex macro which has saved Cambian hundreds of hours of programming time.

Piers Chapman says: “The macro interrogates the solid model geometry and passes the attributes associated with that onto the woodWOP post processor via TPD values. It improves our programming efficiency by automating the process, and we now use it extensively. It’s become essential to the way we work nowadays.”

He says the graphical programming solution supplied with their CNC machine was not capable of dealing with the complexity of the parts they manufacture. “We already knew that ALPHACAM was the industry standard software, so it was the obvious choice of software to translate our solid model information into machine code. Despite this we’re constantly providing feedback to ALPHACAM through their support team, much of which is incorporated into their twice-yearly updates. And we continue to work closely with Andrew Harfield, whose in-depth knowledge of our requirements, and what ALPHACAM is capable of, means that more time saving macros are planned.”

He says the graphical programming solution supplied with their CNC machine was not capable of dealing with the complexity of the parts they manufacture. “We already knew that ALPHACAM was the industry standard software, so it was the obvious choice of software to translate our solid model information into machine code. Despite this we’re constantly providing feedback to ALPHACAM through their support team, much of which is incorporated into their twice-yearly updates. And we continue to work closely with Andrew Harfield, whose in-depth knowledge of our requirements, and what ALPHACAM is capable of, means that more time saving macros are planned.”

He forecasts exciting times ahead for Cambian, which was formed as a result of his background in mechanical engineering and enjoyment of different action sports, including climbing, and riding BMX bikes. “That’s what led us to start working on skate parks and bouldering walls. It was always my ambition to combine my love of engineering and extreme sports, and we’re now doing an interesting hybrid of work within both the architectural and engineering worlds. In order to deliver on these projects, we are constantly advancing our manufacturing facilities, which means new machine tools are very much part of our plans. I don’t know of any other company pushing the boundaries in the way we are at the moment.”

Cambian Engineering Solutions focuses on using wood in the engineering world, where it’s less prevalent than metal. Working mainly within the architectural and engineering sectors, the company provides a complete solution with engineered wood.

Managing Director Piers Chapman explains: “We take the technology from the engineering sector and use that within both the architectural and engineering worlds, but predominantly with wood instead of traditional metal or composites.”

A recent example of bringing wood into an engineering application involved the cockpit for a training flight simulator. This was a high-fidelity system to be mounted on a full-motion frame, and internally was indistinguishable from a real aircraft cockpit. “For this project we replaced a composite, which had two distinct benefits: the product is more sustainable; and it’s considerably more accurate.”

A sizeable part of their business within the architectural sector is providing products for extreme and action sports facilities, such as climbing walls and skate parks. “We frequently create extremely complicated free-form wooden structures on a large scale, and these are all designed and manufactured in-house.”

A sizeable part of their business within the architectural sector is providing products for extreme and action sports facilities, such as climbing walls and skate parks. “We frequently create extremely complicated free-form wooden structures on a large scale, and these are all designed and manufactured in-house.”He says their skate park assemblies comprise tens of thousands of individual, unique components, all modelled, machined, pre-assembled and shipped out in hundreds of separate modular elements.

“It’s critical that all our products are precision machined, whether it’s something like the cockpit where we need to achieve tight tolerances on a small scale, or in the architectural world where we’re assembling off-site, and the cumulative stack-up of any error, multiplied by extensive modular elements, becomes considerable.” He also points out there are quite large tolerances within the engineered wood panels themselves, which is dealt with through their extensive design for manufacture experience.

ALPHACAM is a vital bridge between their NX CAD software and the woodWOP CAM software which runs a Weeke Vantage 200 4.5-axis router and nester from the Homag Group. “Many woodworking companies work with just 2D data, but we do a lot of work via the 3D world, so ALPHACAM is the perfect tool for us.”

The company, operating with seven full-time employees from a 7,000 square foot workshop in West Sussex, uses ALPHACAM to program two fundamentally separate types of part – firstly, planar components which are nested, and secondly, those which need to be 3D machined.

“The planar components are typically 2.5D imported as solid models, and then we use ALPHACAM to extract the features. Where possible we move on to programming in a semi-automatic way using Machining Styles. For the more complex solid models we use 3D machining strategies working with the solid model or surface geometry directly.

“ALPHACAM is the conduit between our 3D design environment and the physical embodiment of the parts we’re manufacturing. Nothing could get made without it.”

However, the unusual 4.5-axis head on their machine tool, meant that programming was not straight forward, and Andrew Harfield, ALPHACAM’s Area Sales Manager, created a complex macro which has saved Cambian hundreds of hours of programming time.

Piers Chapman says: “The macro interrogates the solid model geometry and passes the attributes associated with that onto the woodWOP post processor via TPD values. It improves our programming efficiency by automating the process, and we now use it extensively. It’s become essential to the way we work nowadays.”

He says the graphical programming solution supplied with their CNC machine was not capable of dealing with the complexity of the parts they manufacture. “We already knew that ALPHACAM was the industry standard software, so it was the obvious choice of software to translate our solid model information into machine code. Despite this we’re constantly providing feedback to ALPHACAM through their support team, much of which is incorporated into their twice-yearly updates. And we continue to work closely with Andrew Harfield, whose in-depth knowledge of our requirements, and what ALPHACAM is capable of, means that more time saving macros are planned.”

He says the graphical programming solution supplied with their CNC machine was not capable of dealing with the complexity of the parts they manufacture. “We already knew that ALPHACAM was the industry standard software, so it was the obvious choice of software to translate our solid model information into machine code. Despite this we’re constantly providing feedback to ALPHACAM through their support team, much of which is incorporated into their twice-yearly updates. And we continue to work closely with Andrew Harfield, whose in-depth knowledge of our requirements, and what ALPHACAM is capable of, means that more time saving macros are planned.”He forecasts exciting times ahead for Cambian, which was formed as a result of his background in mechanical engineering and enjoyment of different action sports, including climbing, and riding BMX bikes. “That’s what led us to start working on skate parks and bouldering walls. It was always my ambition to combine my love of engineering and extreme sports, and we’re now doing an interesting hybrid of work within both the architectural and engineering worlds. In order to deliver on these projects, we are constantly advancing our manufacturing facilities, which means new machine tools are very much part of our plans. I don’t know of any other company pushing the boundaries in the way we are at the moment.”