ALPHACAM Automation saves hours of programming time

A.S.H. Plastics - United Kingdom

Contact us

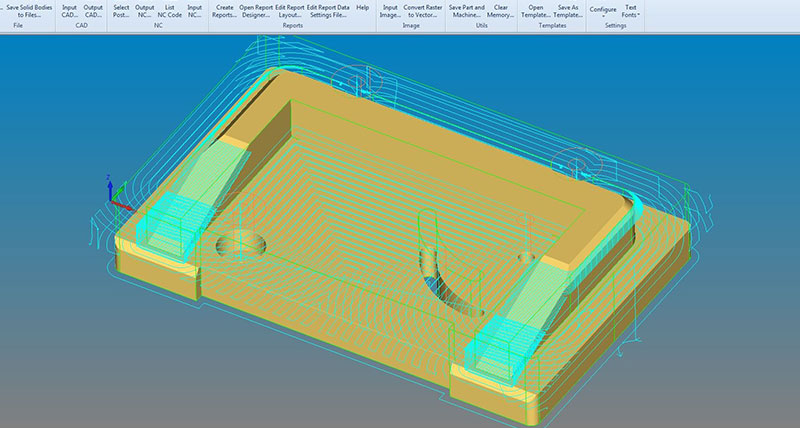

A leading manufacturer of point of sale and display equipment is looking to expand its range of CNC machining capabilities, and says Alphacam Advanced Router, from Vero Software, is integral to its plans.

A.S.H. Plastics already uses Alphacam for high quality, accurate machining of its range of sheet material, and working on complex parts that it would not be able to undertake without it.

A.S.H. Plastics already uses Alphacam for high quality, accurate machining of its range of sheet material, and working on complex parts that it would not be able to undertake without it.

Joint Managing Director David Archer says it is especially valuable for prototyping, as they can generally get a prototype on the machine ready for cutting, within 20 minutes. “When we were programming manually it could take up to an hour, so there’s considerable time saving.”

They invested in Alphacam when they installed a second Rye CNC router. The software now drives their 8 x 4 three-head MG 240, and a two-tabled machine which has four heads and four tool changers. “Both machines are three-axis – which is why we wanted Alphacam, so we could machine 3D parts.”

He says accuracy is of paramount importance to them, especially where they are bonding and gluing parts together, and Alphacam enables them to machine to high tolerances. “If we were to be out by just half a millimetre it would mean the unit wouldn’t fit together, but Alphacam achieves those hyper-critical tolerances for us.”

As well as providing their 3D capability and accuracy, Alphacam readily overcame a particular major challenge facing the upfront CAD part of the operation. “We use Alphacam’s Automation Manager to import several SolidWorks files into the system at once, automatically set up the machining for different materials and thicknesses, as well as nesting. This saves several hours of programming time a week, compared to when we had to open each part file individually, save as a dxf, import it, and then nest it separately.

“It means that once the customer has approved the part design, we can integrate all the SolidWorks part files into Alphacam, the CNC operator then programs those files for each different substrate, they’re sent to the machine, checked and verified, and then go into production.” He says Alphacam’s Advanced Router module ensures a seamless transition from CAD to CAM. “Setting up the geometries and toolpaths is incredibly easy, compared to how it used to be when we had to plot it all out manually and write line after line of G-code. Now, it picks up the required material and thicknesses, and generates everything for us, creating the NC code within minutes – again, saving considerable time.”

Along with the point of sale material for end-users such as Claire’s Accessories and Tesco, A.S.H. Plastics also manufactures a range of products for the engineering sector, including stillages for car dashboards during transit on transporters.

While some of the products only require lasering on their two laser machines, a growing number need to be finished on the CNC routers. “In particular this is when we need to do rebated slots. It means we profile on the lasers, then use Alphacam to create a jig which we’d fix into place on the router, and Alphacam programs the CNC to carry out the routing operations and machine the slots as required.

means we profile on the lasers, then use Alphacam to create a jig which we’d fix into place on the router, and Alphacam programs the CNC to carry out the routing operations and machine the slots as required.

“For example, we needed to create a locking door which we designed in 3D CAD. We had to laser the profile, then used Alphacam to create the NC code for a rebated two-part slot.”

The company, which employs around 35 staff at its 32,000 square foot premises in Wolverhampton, has two front-end operatives working with Alphacam – one of whom also runs the CNC machine, using all aspects of the software – and a further shop floor worker who specialises in running the CNC machines using the programs which have been produced for him.

A member of the Alphacam technical support team helped to set up the software initially, creating their first programs. “We were taking on a new contract which required a certain level of 3D machining, and we didn’t have the capability to carry it out at that time. An Alphacam engineer worked closely with our part files, demonstrating how to program those particular components.”

A.S.H. Plastics already uses Alphacam for high quality, accurate machining of its range of sheet material, and working on complex parts that it would not be able to undertake without it.

A.S.H. Plastics already uses Alphacam for high quality, accurate machining of its range of sheet material, and working on complex parts that it would not be able to undertake without it. Joint Managing Director David Archer says it is especially valuable for prototyping, as they can generally get a prototype on the machine ready for cutting, within 20 minutes. “When we were programming manually it could take up to an hour, so there’s considerable time saving.”

They invested in Alphacam when they installed a second Rye CNC router. The software now drives their 8 x 4 three-head MG 240, and a two-tabled machine which has four heads and four tool changers. “Both machines are three-axis – which is why we wanted Alphacam, so we could machine 3D parts.”

He says accuracy is of paramount importance to them, especially where they are bonding and gluing parts together, and Alphacam enables them to machine to high tolerances. “If we were to be out by just half a millimetre it would mean the unit wouldn’t fit together, but Alphacam achieves those hyper-critical tolerances for us.”

As well as providing their 3D capability and accuracy, Alphacam readily overcame a particular major challenge facing the upfront CAD part of the operation. “We use Alphacam’s Automation Manager to import several SolidWorks files into the system at once, automatically set up the machining for different materials and thicknesses, as well as nesting. This saves several hours of programming time a week, compared to when we had to open each part file individually, save as a dxf, import it, and then nest it separately.

“It means that once the customer has approved the part design, we can integrate all the SolidWorks part files into Alphacam, the CNC operator then programs those files for each different substrate, they’re sent to the machine, checked and verified, and then go into production.” He says Alphacam’s Advanced Router module ensures a seamless transition from CAD to CAM. “Setting up the geometries and toolpaths is incredibly easy, compared to how it used to be when we had to plot it all out manually and write line after line of G-code. Now, it picks up the required material and thicknesses, and generates everything for us, creating the NC code within minutes – again, saving considerable time.”

Along with the point of sale material for end-users such as Claire’s Accessories and Tesco, A.S.H. Plastics also manufactures a range of products for the engineering sector, including stillages for car dashboards during transit on transporters.

While some of the products only require lasering on their two laser machines, a growing number need to be finished on the CNC routers. “In particular this is when we need to do rebated slots. It

means we profile on the lasers, then use Alphacam to create a jig which we’d fix into place on the router, and Alphacam programs the CNC to carry out the routing operations and machine the slots as required.

means we profile on the lasers, then use Alphacam to create a jig which we’d fix into place on the router, and Alphacam programs the CNC to carry out the routing operations and machine the slots as required. “For example, we needed to create a locking door which we designed in 3D CAD. We had to laser the profile, then used Alphacam to create the NC code for a rebated two-part slot.”

The company, which employs around 35 staff at its 32,000 square foot premises in Wolverhampton, has two front-end operatives working with Alphacam – one of whom also runs the CNC machine, using all aspects of the software – and a further shop floor worker who specialises in running the CNC machines using the programs which have been produced for him.

A member of the Alphacam technical support team helped to set up the software initially, creating their first programs. “We were taking on a new contract which required a certain level of 3D machining, and we didn’t have the capability to carry it out at that time. An Alphacam engineer worked closely with our part files, demonstrating how to program those particular components.”