Agricultural operations do not end at harvest: the importance of analysis and management of results

This stage ensures more efficiency and, consequently, reduces expenses and increases certain investments

Preparing the soil, planning the operations, carrying out the planting, applying the inputs, monitoring the activities and carrying out the harvest. Many see this as the complete cycle of agricultural activities, but there is one more essential factor for success in agribusiness: analysis and results management. Missing this stage can completely impair the work of a producer or agricultural and forestry company. That’s why, nowadays, more and more technologies are available to assist in this process.

"By evaluating and understanding all the actions that were taken in a transaction, it is possible to invest in the best attitudes so that the next harvest is even more operationally efficient. No one is exempt from mistakes and free from unforeseen circumstances, for example, but the way to deal with these situations — seeking to understand them to avoid them, or simply ignoring them — is the great difference between those who fail and those who succeed", defends Bernardo de Castro, president of Hexagon’s Agriculture division, a company that develops and provides digital agricultural and forestry solutions.

Through technologies such as sensors and on-board computers integrated into the field machinery, all information that allows accurate understanding of the reality of what happens in rural areas is recorded. Based on this, and with the support of operational management and business intelligence solutions, it is possible to make an intelligent analysis of the processes, acquiring a strategic vision for making better decisions in the future.

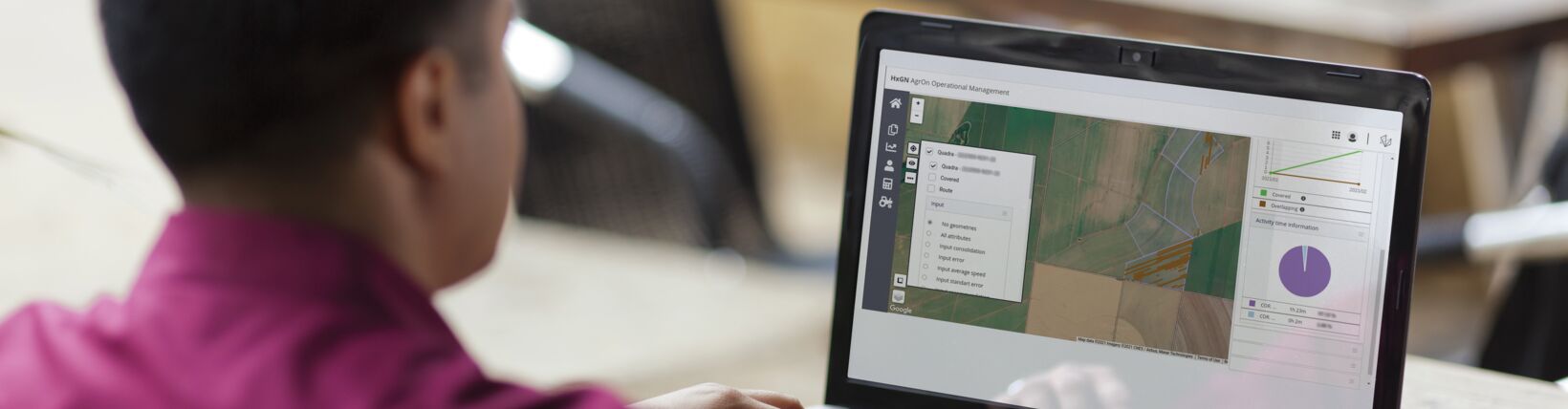

HxGN AgrOn Operational Management software, developed by the division, for example, is a geo-referenced information management system of agricultural and forestry operations, whether in the planting, cultivation or harvesting phase. With advanced and automated processing, the product collects data from the displays installed on the machines and makes reports, maps, graphs and exportable tables available on an online platform.

"With this real information in hand, companies and producers can have much greater control of the operations under their management, identifying the most sensitive phases of production and taking the necessary actions to adjust them. This guarantees more efficiency and, consequently, reduction of expenses and increase in certain investments ", reinforces Bernardo.

An important management example is that of the total inputs applied (in kg/ha) — whether fertilisers, herbicides, pest control or any other type of product. With this value in hand, it is possible to analyze if there was over or underdosage, what was the percentage of the deviation, if it will be necessary to do some reapplication action and so on. As the data are georeferenced, it is also available which exact areas have failed the application, what was the total area executed and what was the speed of the operation. With this, complementary actions such as a reduction in the stock of inputs, control of work orders and payments to third parties can be carried out automatically.

Another collaboration of management technologies is the analysis of time and income issues, which allow a better management of the assets involved in the operations. As the tools provide the measurement of topics such as area covered by the machinery, hours of work and fuel spent, they are able to verify exactly the total productive and unproductive time.

The gains that this management provides are many, such as negotiation with service providers, operator bonus policies, preventive and corrective maintenance decisions of the machines and planning of the best trajectory of the vehicles for fleet management.

Real-time management

With the advancement of innovations in the field, currently, this strategic management does not need to be carried out only after harvest, but also throughout the agricultural operation.

Telemetry and connectivity already allow the collection and sharing of data with remote command centers, where teams of operators can stay connected with field activities even from a distance.

All the information that arrives through the system about the execution of operations can be continuously compared with the planned goals, in addition to giving rise to performance analyzes and enabling quick decision making to correct problems. "If the manager sees that any machine is stopped, out of speed or has a deviation in the application, for example, it is possible to contact the operator at the same time to check what’s happening and solve the issue, which prevents losses and increases productivity," emphasises the president of Hexagon's Agriculture division.