Advanced technology meets expertise: the secret to DPS’s success in mould design

by Alberto Marelli, Costruire Stampi reproduced with permission from Costruire Stampi, April 2022

Engineering Reality 2023 volume 2 edition

Empowering Makers for an autonomous sustainable future

DPS relies on VISI CAD/CAM to guarantee high-quality moulds for automotive lighting

DPS S.A.S. (Di Pelosi Romolo & C.) was founded in 1977 and is based in Turin, Italy. The company specialises in the design and construction of moulds, especially for

the automotive sector. As a leader in manufacturing single-colour, multi-colour, multi-material thermoplastic, thermoset, and compression moulds, DPS’ facilities are state-of-the-art. Their stringent quality requirements produce superior moulds that exceed industry standards. These are challenging moulds but with a common distinctive trait: quality must be of the highest level despite product complexity.

All plastic injection moulds from DPS feature three critical success factors: the skill and expertise of their team, leading-edge technology, and detailed, repeatable processes. To ensure success, DPS has assembled a team of expert engineers, designers, machine operators, and project managers whose combined experience in injection moulding is second to none. DPS excels at creating moulds for headlights, taillights, fog lamps, reflectors, side markers, dome lamps, instrumentation, and other

vehicle lighting. “We take great pride in getting our plastic injection moulds right the first time, saving our customers a great deal of production time and cost,” says Claudio Rizzo, Head of DPS.

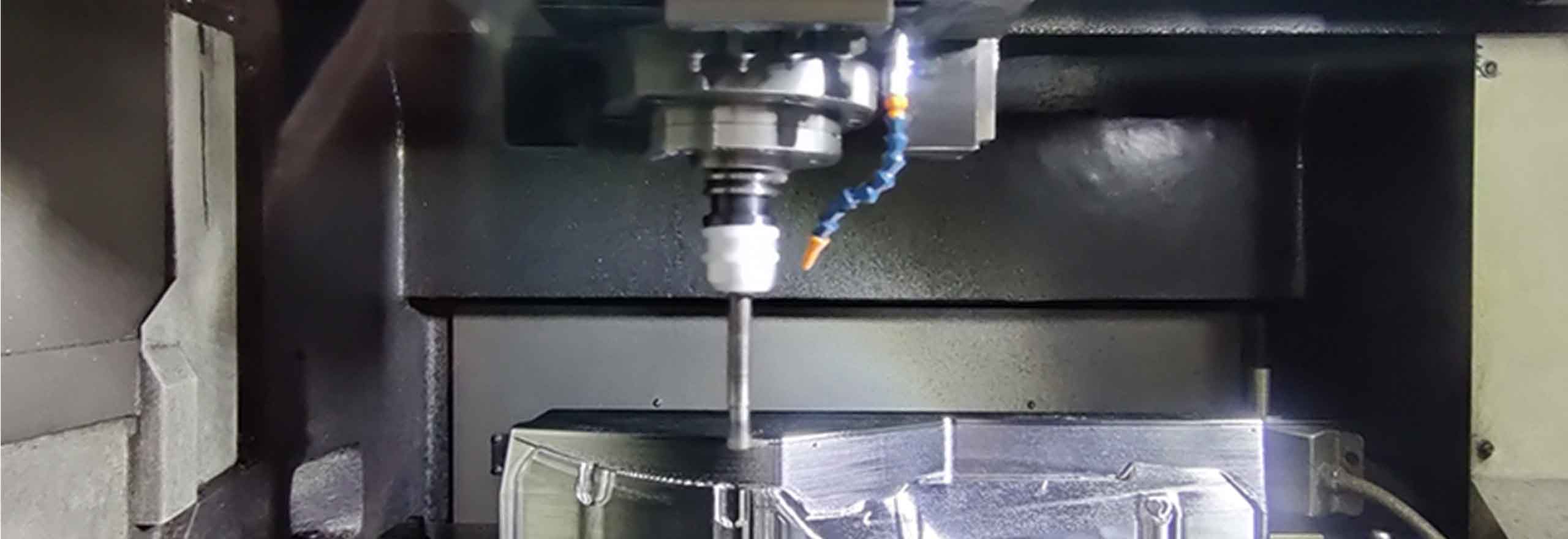

High-performance, state-of-the-art machines guarantee precision and accuracy

“We’ve built a reputation for excellence in product quality and customer service. When we first meet with a client through developing the product design, prototyping, and production, we base our approach and process on mutual trust and collaboration. We are small but powerful. As a Tier 3 supplier, we produce moulds for international brands such as Stellantis, Ferrari, the Volkswagen Group, Renault, and Ford. This attention to quality has never failed us,” explains Rizzo.

“Automotive optical moulds are not easy to make, as the precision and accuracy of the finish required is something that only a few can guarantee,” he says. “To be competitive, it is necessary to constantly keep up to date with technology and have state-of-the-art and high-performance machines and software. We must keep our costs low while optimising processes. Our machines also work all night and on weekends. At night, the milling machines perform finish machining operations, while on the sinker and wire EDM, we perform roughing and finishing operations.”

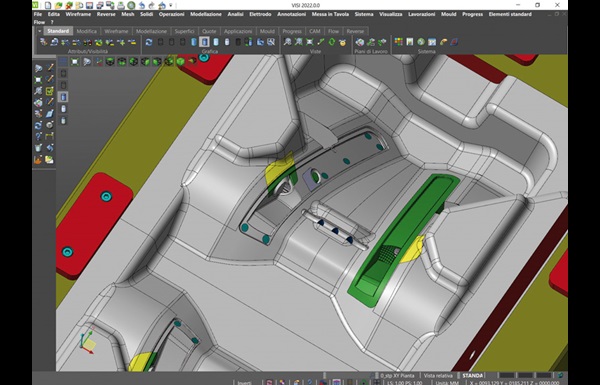

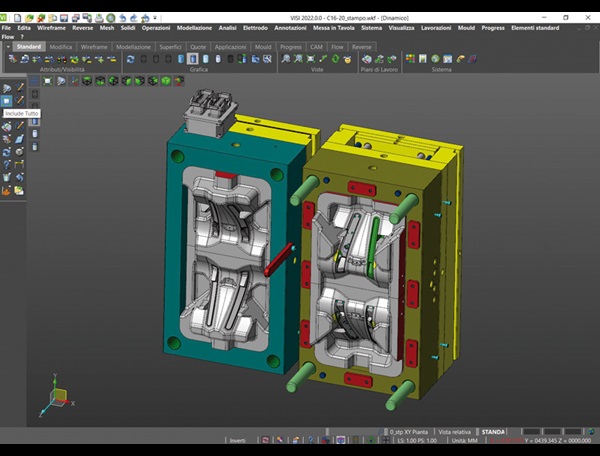

Rizzo continues, “Our customers demand more from lighting components, which challenges us to create more complex mechanisms to bring the desired forms and functions to reality. Usually, companies come to us with the mathematical model of the piece, and we develop high-performance moulds through our advanced mould design and engineering solutions from Hexagon’s VISI CAD/CAM software. Our highly skilled engineers create core, cavity, inserts, and lifters and then analyse and simulate the moulding with the VISI Flow software to create the digital twin of the plastic injection process.

”

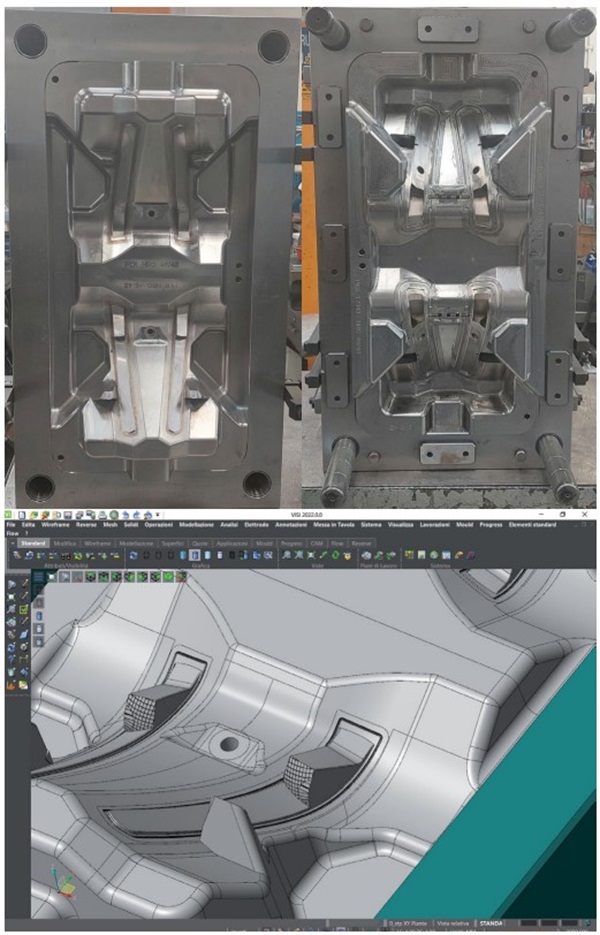

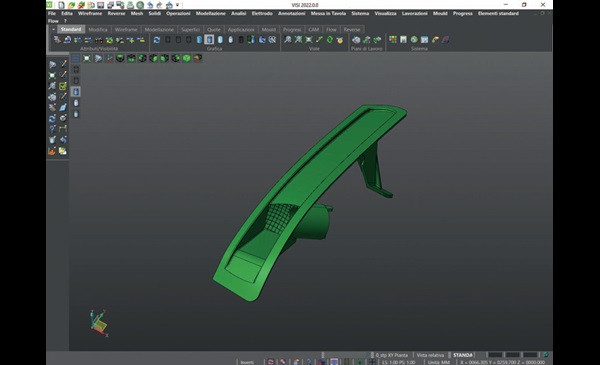

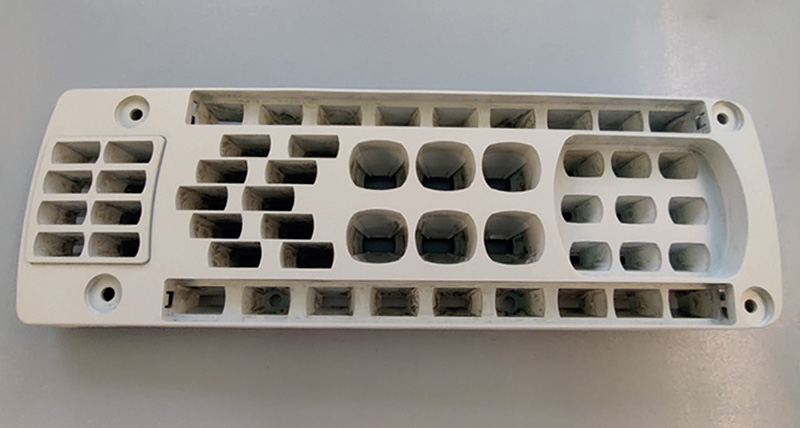

Figure 2. Core and cavity for rear view mirror blinker lens mould virtually in VISI (top) and physically (bottom) - a true digital twin.

Figure 3. Detailed view of injection gate location for melt delivery on the core.

Figure 3. Detailed view of injection gate location for melt delivery on the core.

Figure 4. Detailed view of the injection pins locations for part extraction on the cavity.

Figure 5. Various automotive injection moulded components made by DPS

Figure 6. Rear view mirror blinker component details.

Improving analysis accuracy and reducing model preparation and calculation times

VISI Flow is a solution for plastic injection moulding analysis and simulation. All phases of part production benefit from the moulding design approach: concept design, part engineering, mould design and industrialisation, and optimisation of moulding parameters. VISI Flow is a prediction and analysis tool that allows you to perform a significant number of analyses accurately with reduced model preparation and calculation times enabling multiple comparative studies in reduced time.

VISI Flow allows accurate analyses during the piece design phase and before the mould design; these analyses make it possible to identify and solve problems. Typical issues to identify and optimise include gate locations, accurate filling simulation, aesthetic issues, fibre orientation, meld and weld lines, voids, air traps, vents, fibre orientation, warpage, cooling analysis, and layout when modification costs are still minimal in the project’s early phase.

The collaboration between DPS and VISI mentioned by Rizzo dates back to the mid-nineties. “We were among the first companies in Italy’s automotive corridor in Turin to use their product. We knew of the existence of other software, but we immediately believed in the VISI product, which was perfectly in line with our needs, and the results proved us right. Over the years, the VISI system has made great strides, expanding and becoming more and more complete, an evolution that we have experienced in every step and has supported us on our growth path. Today VISI is a comprehensive product that excels in 3D surface and solids modelling, mould design, injection analysis, 3-5 axis machining, wire EDM, and design of sinker EDM electrodes.”

Increasing flexibility and simplicity and guaranteeing high precision across all operation

In summary, Rizzo outlines the following three strengths of VISI software. “First of all, the extreme flexibility in modelling a piece. The second noteworthy aspect is the remarkable simplicity of use: it is sufficient to indicate only few parameters to start programming. Third (last but not least), the guaranteed high precision across all operations.”

“VISI is an excellent product that helps us to simplify our work. Since we switched to solids modelling, the benefits have immediately become evident. Features such as automatic recognition of design changes, draught angle visualisation, multiple split line analysis, core and cavity separation, and dynamic 3D tool design are invaluable to our process. Integrating solids and surfaces into a single file provides maximum flexibility for moulding simulation. This is a real benefit because it allows us to minimise our file management and revision control process,” underlines Rizzo.

DPS’s high-quality standards and knowledge of lens-grade plastic materials make it a leader in the automotive lighting industry.

Figure 7. Injection moulded component for motorbikes.

Figure 9. Machining of the mould.

Many injection moulding service providers manufacture plastic parts and components for the automotive industry. Fewer moulders, however, provide custom-moulded plastic parts for automotive lighting. Whether traditional lighting or newer automotive LED plastics, DPS leverages decades of experience, cutting-edge technology, and collaborative process for delivering high-quality plastic lenses to European automotive manufacturers and suppliers.