Forest management: technology ensures advanced and real-time analytics for efficient results

By Ronaldo Soares, Forest Manager at Hexagon's Agriculture division

The absence of good management can completely harm a business, especially when it comes to long-term results. Therefore, in forest operations — which take years to complete — keeping management up to date is something that makes all the difference.

However, although this is a major challenge for managers, with the support of increasingly advanced technologies, today it is already possible to understand practically everything that happens in forests. Through sensors, hardware and software, data and analysis to solve problems, improve processes and obtain more productivity and profit become increasingly a reality in forest operations.

Operational management

With support for sensors and onboard controllers installed in forestry machinery, management software is often widely used for an operational and qualitative view. An example of data analysed, for example, is the total of inputs — whether fertilisers, herbicides, pest control or any other type of substance for forest implantation and maintenance — applied (in kg/ha).

With this value in hand, it is possible to analyse if there was over or underdosage, what was the percentage of the deviation, if it will be necessary to do some reapplication action and so on. As the data are georeferenced, it is also available which exact areas have failed the application, what was the total area executed and what was the speed of the operation. With this, complementary actions such as a reduction in the stock of inputs, control of work orders and payments to third parties can be carried out automatically. Management software that values the usability and practicality of the manager also have tools such as email alerts with information on the status of the area executed, deviations in the application of the input or in the recommended spacing, for example. Notifications add a lot to the immediate decision making of the manager, optimising structures and resources and ensuring operational quality.

It is also worth noting that georeferenced data can be exported and inserted into other systems for interpolation with external information. A common example is the crossing with the forest inventory, which points out how many m³ of wood were produced. Thus, it is possible to analyse the relationship of the final productivity of the forest with the quality of operations in the implementation and maintenance of the same (applications of fertilisers, correctives, herbicides, formicide bait etc.), as well as with other interpolation analyses such as area slope and soil analysis.

Asset Management

Another collaboration of forest management technologies is the analysis of issues of times and yields, which allow a better management of the assets involved in the operation.

As the tools provide the measurement from second to second, they are able to verify exactly the total productive and unproductive time at different levels of grouping: the yield per machine, per operator, by geospatial classification — plot, farm or unit, for example — by activity and by time.

The information is interesting for analysing issues such as operational availability, effective yield and overall efficiency. There are many gains for the manager from the good use of this data, such as negotiation with service providers, operator bonus policies when checking their operational productivity or even decisions on preventive and corrective maintenance of machines and implements. In addition, the data facilitates operational planning with the understanding of how many working days, how many people and how many resources will be necessary to perform a given activity.

Analytical and integrated management

In general, the management systems available for forest operations monitor and consolidate various information, which are presented to managers and assist in facilitating processes. However, when the company is prepared and willing to work analytically with this data, it is possible to achieve even more efficient results. The optimisation of non-productive time to reduce overtime, the design of strategies to increase income among service providers and the agility in corrective action in the face of identified errors are some examples of how this management is able to change forest production.

Other sectors of the company can also take advantage of the data collected to advance productivity, in an integrated and collaborative management. The supply area, for example, can automatically record how many inputs were used or what amount needs to be paid to service providers in view of the hectares worked.

As everything is recorded in a historical way, the planning sector can use it to monitor activities and monitor goals, creating contingency actions when necessary and drawing up increasingly realistic future plans. The research team, in turn, can create highly reliable databases and generate technical recommendations from the georeferenced information of the software, which have a high level of detail.

For the governance area, these same data serve to monitor and reduce environmental risks, in addition to being adequate ways to prove compliance with rules and subsidy to obtain international certifications.

Real-time management

With the advancement of innovations in the field, currently, management can be carried out from the telemetry and connectivity of the machine — which guarantees the collection and sharing of data remotely. In a control room, away from the farm, managers follow what is happening in the operation, with a map of the tractors in real-time.

This data is very useful for quick decision-making and troubleshooting. If the manager sees that any machine is stopped, out of speed or with deviation in the application, for example, it is possible to contact the operator at the same time to check what is happening and solve the issue.

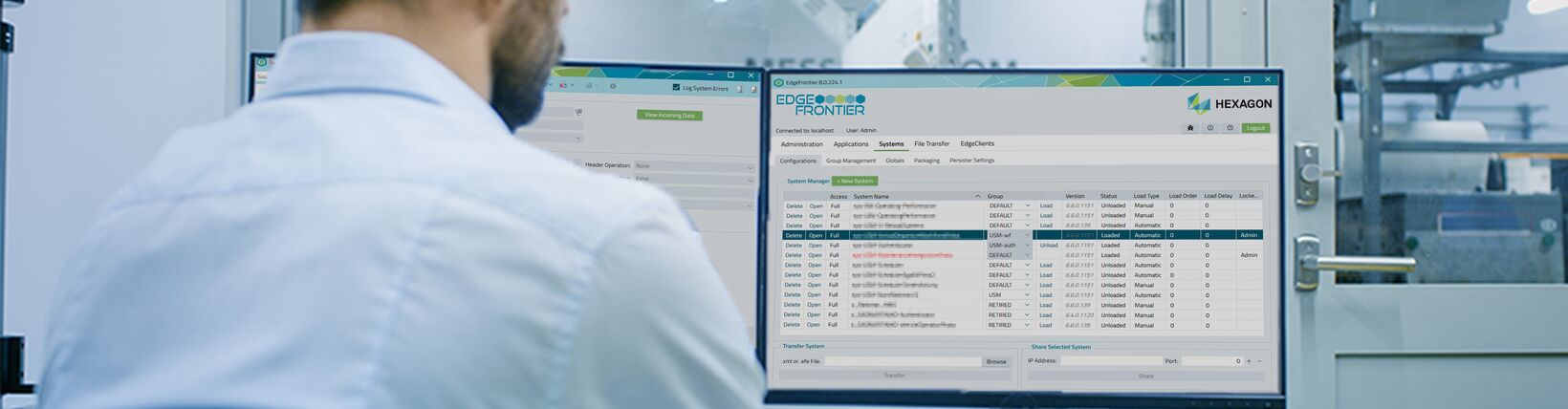

Management systems such as Hexagon also allow the creation of workflow rules, that is, the parameterisation and configuration of a routine that must be followed by forestry machinery. If these prescribed activities are not performed correctly for any reason, an alert is sent for the action to be explained. In fact, alarms can be set up visually and audibly for the operator, some of which are very important for the safety of the team — such as maximum speed allowed, machine slope and risk of tipping. Other alarms can be used for better operational performance and cost reduction, such as idle engine warning or low productivity.

In the workflow, machine telemetry solutions such as reading revolutions per minute (RPM) and fuel level, associated with data from other sensors, geographical positioning, definition of electronic fence, operator, pairing between vehicles, etc., ensure a more autonomous recording of activities during operation, minimising manual notes.

On the other hand, it is worth mentioning that, due to the connectivity challenges that still exist in agricultural and forestry areas, this information shared in real-time is limited. More historical, analytical and consolidated data, which do not require such agile action, are made available after the work is carried out in the case of areas that do not have a wide connection.